Pre-fabricated assembled steel structured residential cable and electric wire laying system and construction method therefor

A prefabricated assembly and steel structure technology, applied in cable laying equipment, electrical components, etc., can solve problems such as prefabricated wall damage, and achieve the effect of reducing the laying radius, convenient and convenient construction, and easy modification or maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

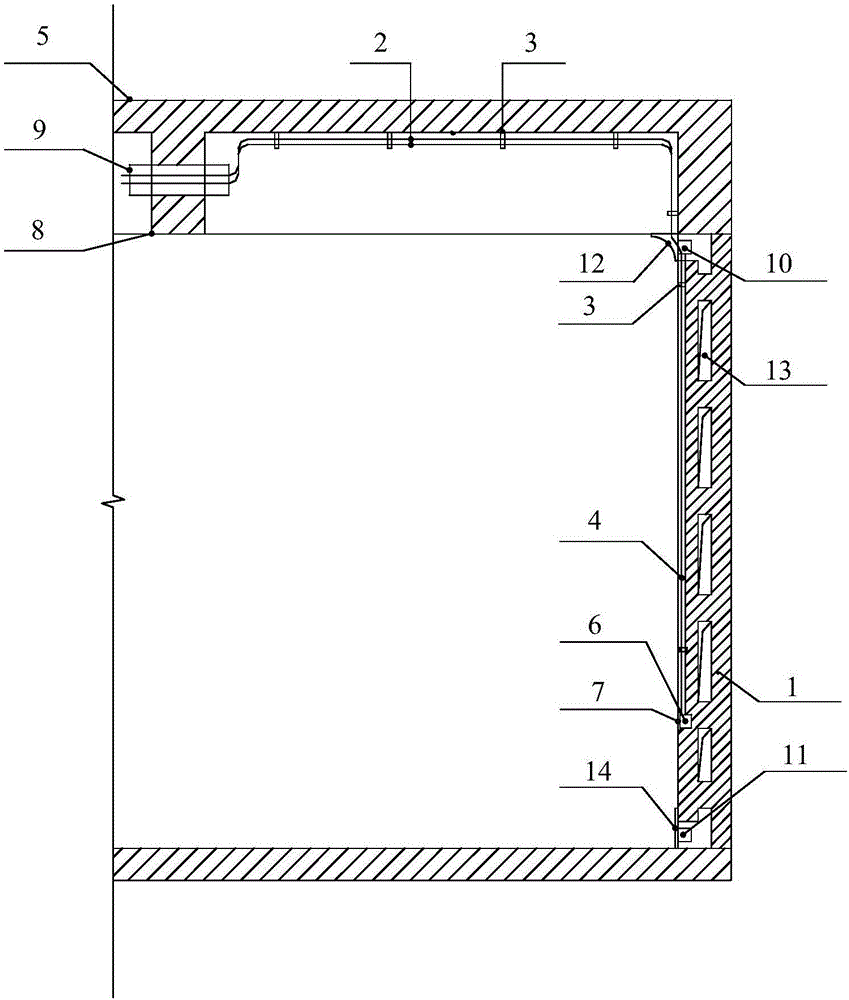

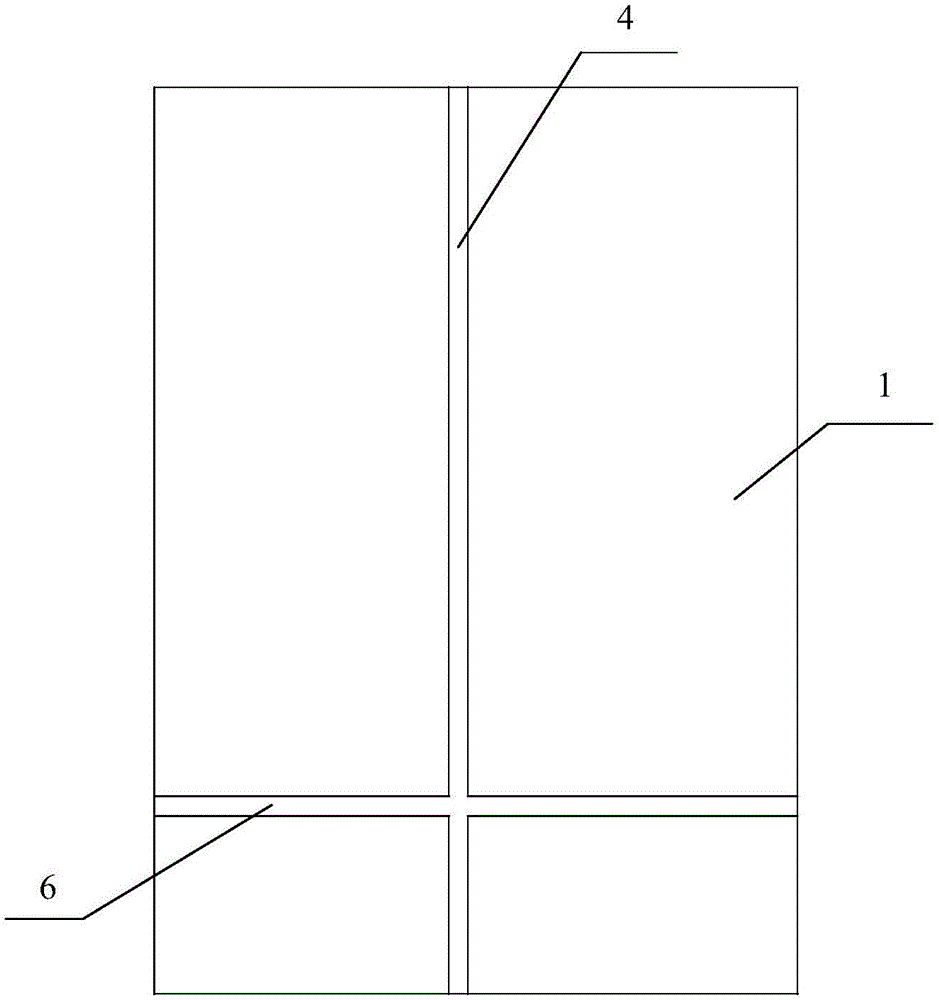

[0028] see figure 1 and figure 2 , this embodiment discloses a cable and wire laying system for a prefabricated steel structure house, including several hydroelectric wall panels 1 and several cables 2 (which can be indoor cables), and the hydroelectric wall panels 1 are distributed according to the indoor electricity demand. In the prefabricated and assembled steel structure house, the water and electricity wallboard 1 is provided with a vertical branch line trough 4 for laying cables 2, and the cables 2 are fixed in bundles by a plurality of clips 3, and the clips 3 are glued to each other. Knotted in the vertical branch pipe trunking 4, the upper end of the cable 2 walks along the ceiling in the suspended ceiling to the indoor distribution box (not shown), and the upper end of the cable 2 extends into the suspended ceiling and walks to the indoor distribution box. The inner distribution box is connected, that is, the upper end of the cable 2 extends into the ceiling and w...

Embodiment 2

[0036] read on figure 1 and figure 2 , the present embodiment provides the construction method of the prefabricated and assembled steel structure residential cable and wire laying system described in the first embodiment, including the following steps:

[0037] Step 1, providing several water and electricity wall panels and several cables.

[0038] Step 2: Install the hydropower wallboard in the prefabricated steel structure house according to the indoor electricity demand. The hydropower wallboard 1 is provided with a vertical branch pipeline trough 4 for laying cables 2, and the The cables 2 are fixed in bundles by several clips 3, and the clips 3 are bonded in the vertical branch pipe trough 4, and the upper ends of the cables 2 walk along the top plate 5 in the suspended ceiling to the indoor distribution box, The lower ends of the cables 2 are respectively connected to sockets or switches. On the one hand, in this embodiment, by laying the cable 2 inside the hydropowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com