Cubic carbon material from hemicellulose and preparation method thereof

A technology of hemicellulose and cubic shape, which is applied in the field of cubic carbon materials and its preparation, can solve the problems of insufficient biomass carbon material precursor materials, poor material appearance, complicated preparation process, etc., and achieve low price and low cost. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a cubic carbon material from hemicellulose, specifically comprising the following steps:

[0028] 1) Cut pomelo peel into small pieces, wash, dry and grind into powder.

[0029] 2) Dissolve 6 g of pomelo peel powder and KOH solution at a mass ratio of 1:4, stir and filter the obtained supernatant to make it neutral, mix ethanol with the obtained supernatant and wash by centrifugation to obtain a mixture.

[0030] 3) The mixture was vacuum-dried in a vacuum drying oven, and vacuum-dried at 80° C. for 6 hours to obtain a hemicellulose precursor.

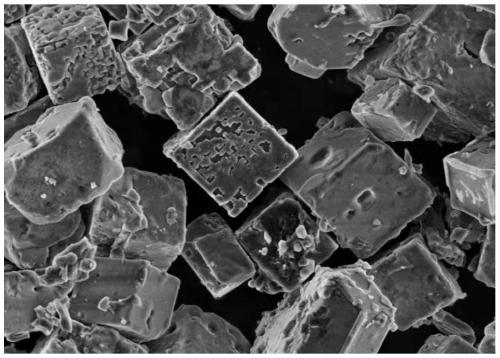

[0031] 4) Combine hemicellulose precursor with activator H 3 PO 4 After mixing, calcining at a high temperature of 600° C. for 2 hours to obtain a semi-fibrous cubic carbon material. From figure 1 It can be seen from the SEM image that the prepared carbon material has a relatively regular morphology, generally a cubic structure. It shows that this method is easy to operate and low in cost, and it is ...

Embodiment 2

[0033] A preparation method of a cubic carbon material from hemicellulose, specifically comprising the following steps:

[0034] 1) Cut pomelo peel into small pieces, wash, dry and grind into powder.

[0035] 2) Dissolve 8 g of pomelo peel powder and KOH solution at a mass ratio of 1:4, stir and filter the obtained supernatant to make it neutral, mix ethanol with the obtained supernatant and wash by centrifugation to obtain a mixture.

[0036] 3) The mixture was vacuum-dried in a vacuum drying oven, and vacuum-dried at 70° C. for 8 hours to obtain a hemicellulose precursor.

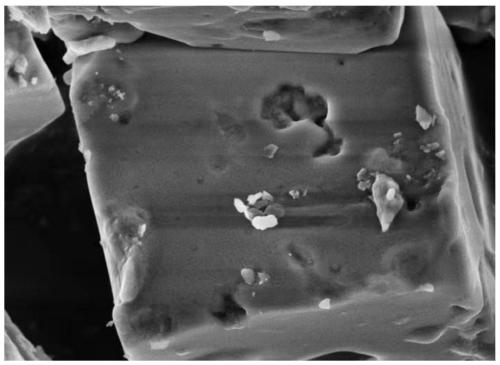

[0037] 4) Combine hemicellulose precursor with activator H 3 PO 4 After mixing, calcining at a high temperature of 800° C. for 3 hours to obtain a semi-fibrous cubic carbon material. From figure 2 It can be seen from the SEM image that the prepared carbon material has a relatively regular morphology, generally a cubic structure. However, due to the high calcination temperature, the structural surfac...

Embodiment 3

[0039] A preparation method of a cubic carbon material from hemicellulose, specifically comprising the following steps:

[0040] 1) Cut pomelo peel into small pieces, wash, dry and grind into powder.

[0041] 2) Dissolve 10 g of pomelo peel powder and KOH solution at a mass ratio of 1:4, stir and filter the obtained supernatant to make it neutral, mix ethanol with the obtained supernatant and wash by centrifugation to obtain a mixture.

[0042] 3) The mixture was vacuum-dried in a vacuum drying oven, and vacuum-dried at 70° C. for 8 hours to obtain a hemicellulose precursor.

[0043] 4) Combine hemicellulose precursor with activator H 3 PO 4 After mixing, calcining at a high temperature of 600° C. for 2 hours to obtain a semi-fibrous cubic carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com