Design method of improving repetitive controller applied to grid-connected inverter current control

A repetitive controller, current control technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc. The output waveform has a large impact and the stability margin of the control system is low, so as to achieve the effect of improving the stability margin, high steady-state tracking accuracy, and good dynamic response capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

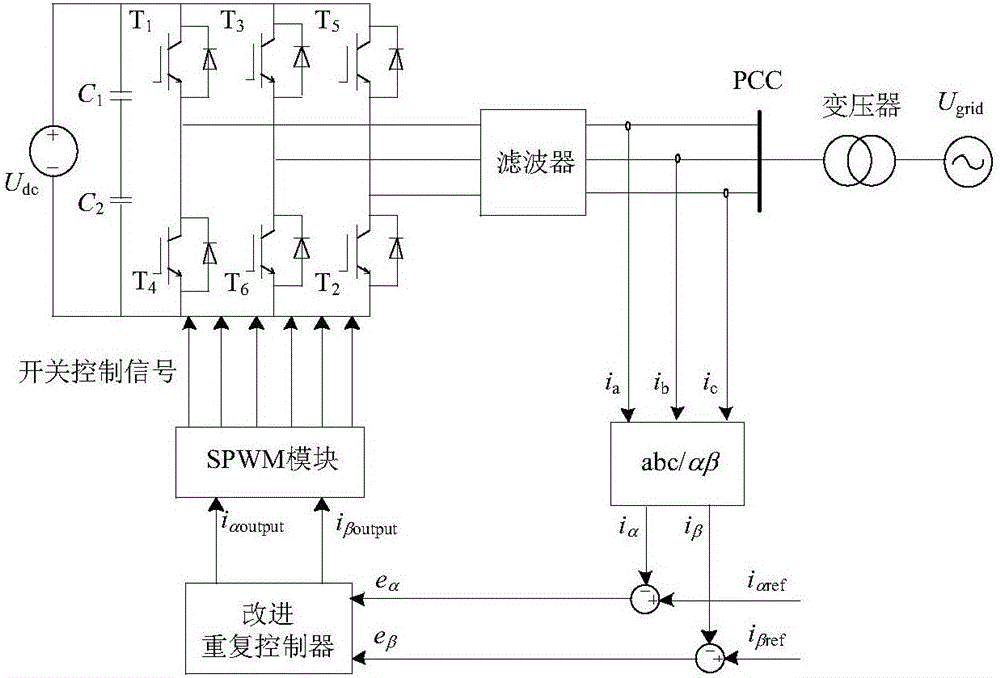

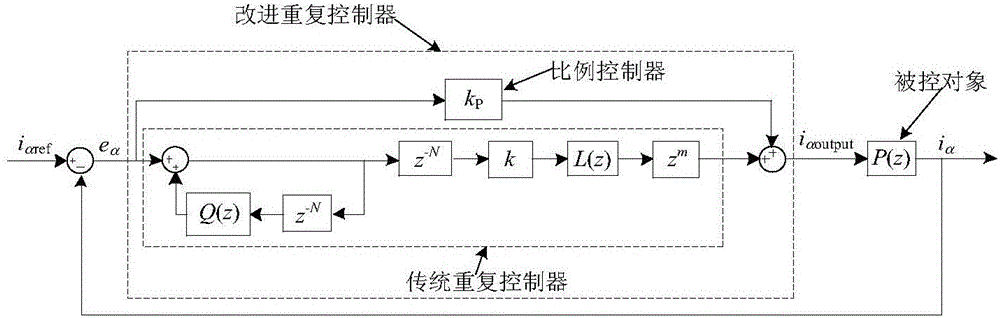

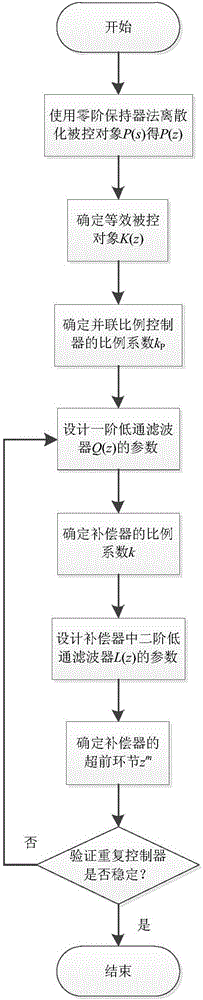

[0055] The specific implementation of the present invention will be described below with reference to the accompanying drawings and by taking the LCL type grid-connected inverter as an example, so that those skilled in the art can better understand the present invention.

[0056] In this embodiment, the grid-connected inverter mainly includes two parts, a main circuit and a control circuit.

[0057] The main circuit includes: DC voltage source, three-phase half-bridge inverter circuit and LCL filter. Among them, the DC voltage U dc =400V; Inverter side inductance L in LCL filter 1 =0.3mH, grid side inductance L 2 =1mH, filter capacitor C=100μF, damping resistance R=1Ω on the capacitor branch; the three-phase half-bridge inverter circuit is connected to the common connection point through the LCL filter, and then connected to the external power grid through the step-up transformer.

[0058] The control circuit includes: abc / αβ coordinate system transformation module, improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com