Brushless direct current motor control system based on electrolytic capacitor-free inverter and control method

A technology of brush DC motor and electrolytic capacitor, which is applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the problems of introducing switching loss, low system reliability, complex control circuit, etc., and achieve high power factor , Control is simple and effective, reducing the effect of commutation torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only for explaining the present invention, and are not intended to limit the scope of the present invention.

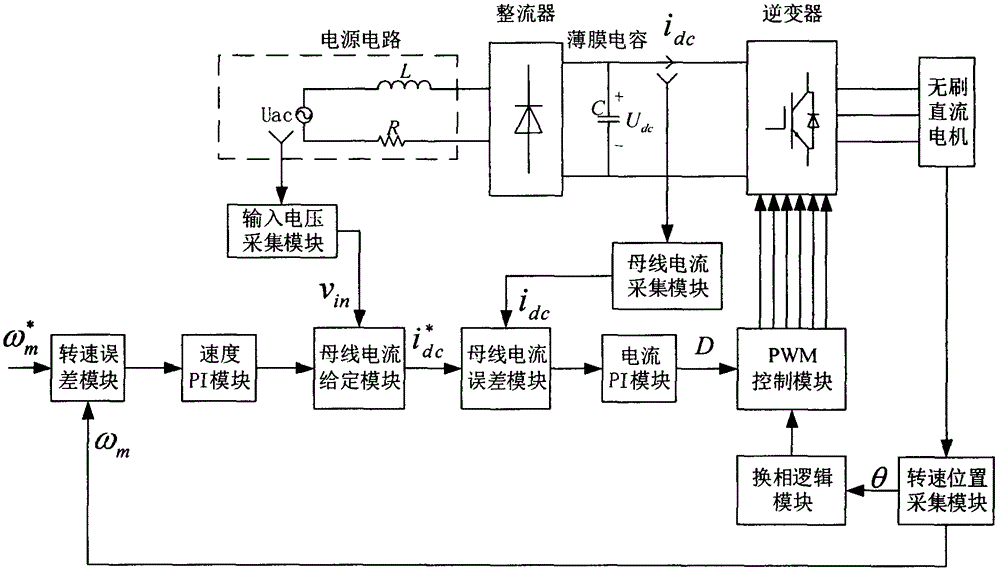

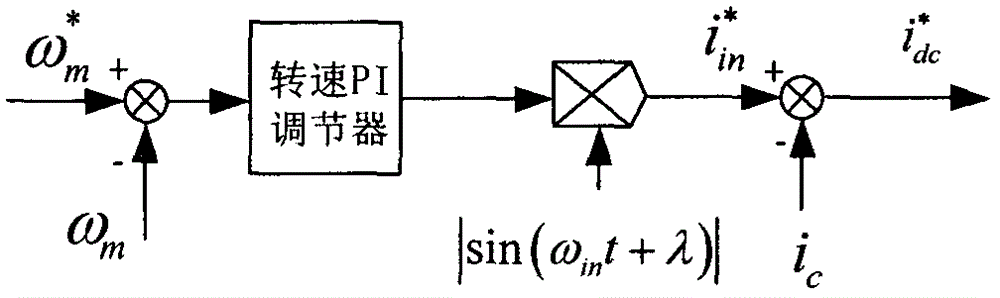

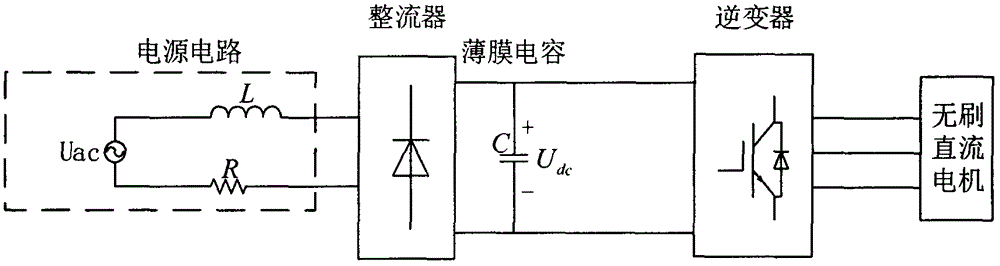

[0060]The invention discloses a brushless DC motor control system based on a non-electrolytic capacitor inverter. figure 1 It is a structural block diagram of the present invention, including: a power supply circuit, a rectifier, a film capacitor, an inverter, a motor, an input voltage acquisition module, a bus current acquisition module, a speed position acquisition module, a speed error module, a speed PI module, and a given bus current module, bus current error module, current PI module, PWM control module, commutation logic module.

[0061] The power supply circuit is a single-phase AC power supply for providing single-phase AC power to the rectifier.

[0062] The rectifier is a single-phase uncontrolled rectifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com