Single-tube-driven electromagnetic heating circuit

A heating circuit, electromagnetic technology, applied in induction heating, induction heating control and other directions, can solve the problems of difficult to precise control, large temperature fluctuations, circuit interference, etc., to achieve the effect of easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

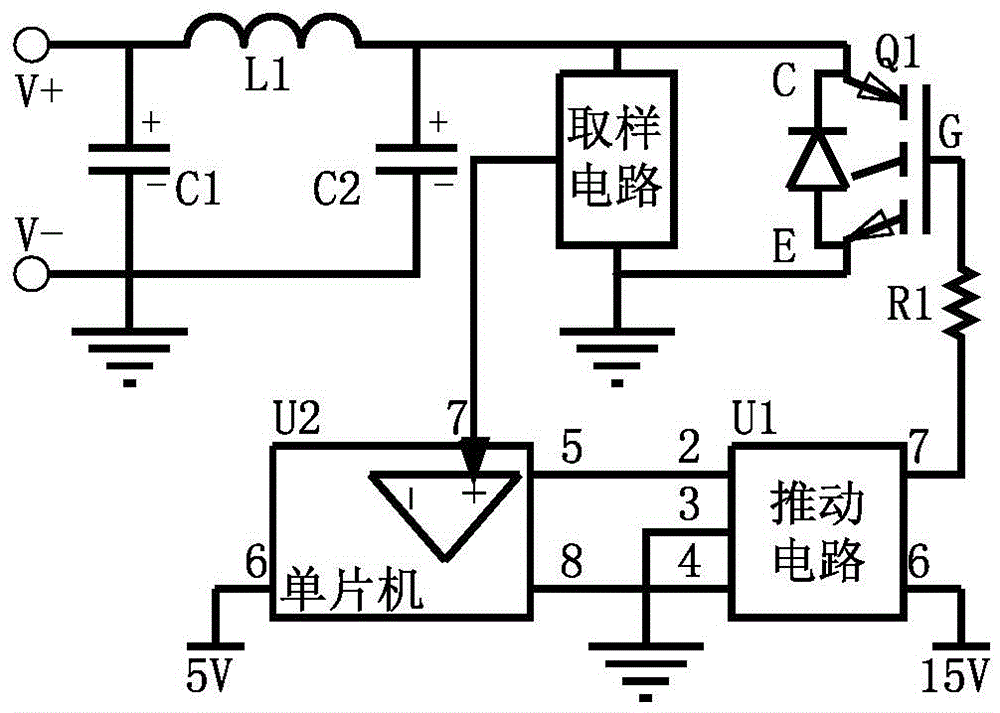

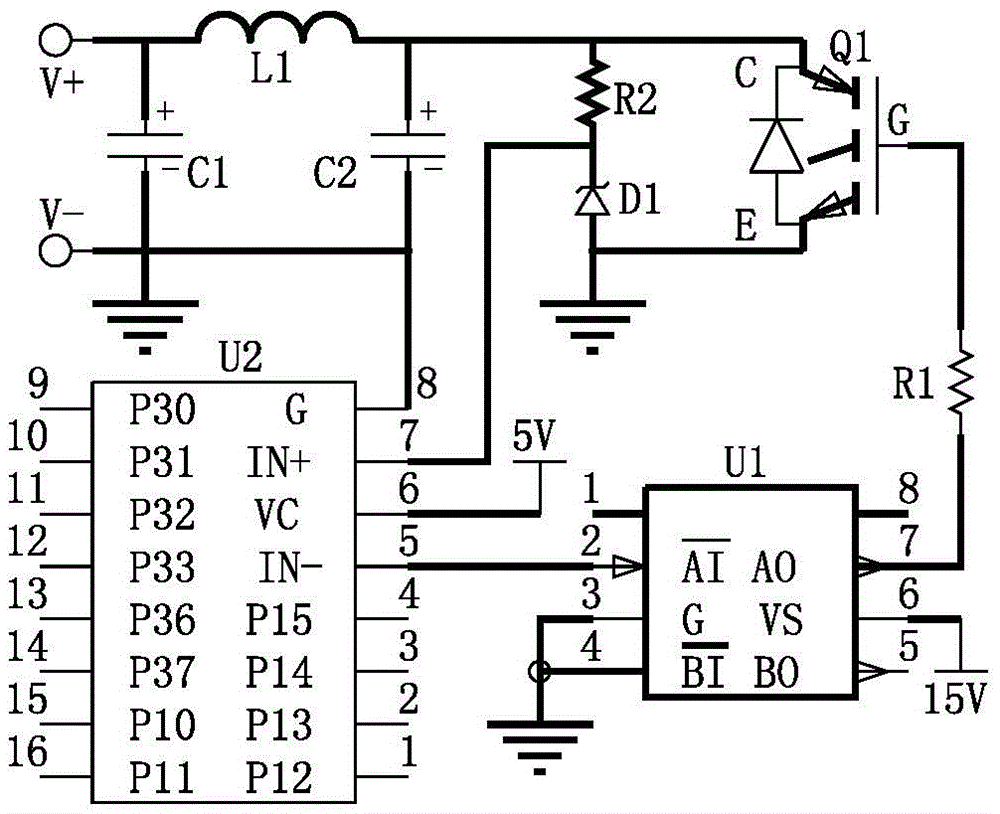

[0013] like figure 1 and 2 A single-tube drive electromagnetic heating circuit is shown, including filter capacitor C1, excitation coil L1, resonant capacitor C2, IGBT switch tube Q1 (including damping diode), sampling circuit, single-chip circuit (including voltage comparator) and driving Circuit, the filter capacitor C1 negative pole, the resonant capacitor C2 negative pole and the emitter of the IGBT switch Q1 are connected and grounded, the filter capacitor C1 positive pole is connected to the DC positive pole, and the excitation coil L1 is connected in series between the filter capacitor C1 positive pole and the resonant capacitor C2 positive pole, The positive pole of the resonant capacitor C2 is connected to the collector C of the IGBT switch tube Q1; the driving circuit U1 uses IR4426 or IR4428 chips (both contain two sets of driving circuits), and the 6 pins of the driving circuit U1 are connected to the 15V power supply, and the 3 pins and 4 pins are grounded , 7 pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com