Reactivity control in a molten salt reactor

A reactor, reactive technology used in the control of fission reactions to solve problems such as being toxic, complex and expensive, and volatile metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

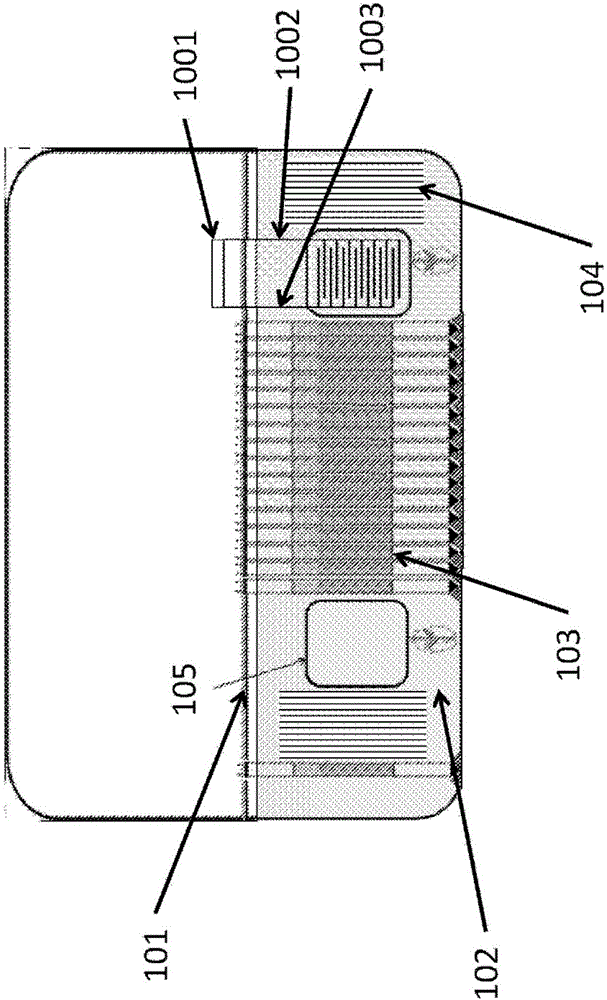

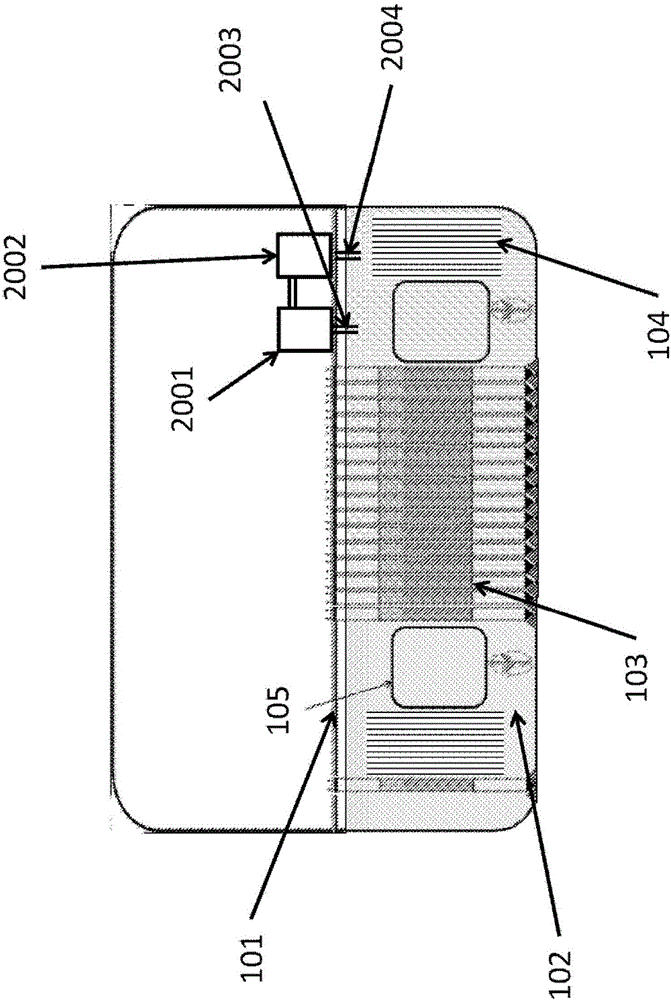

Image

Examples

Embodiment Construction

[0015] It should be noted that, as stated in this document, the following terms have the following meanings which are standard in the chemical field:

[0016] Element: A single type of atom (when used to describe a component of a compound) or a chemical formed from a single type of atom (when used to describe a substance). Compound: A chemical comprising two or more different elements bonded together by electricity.

[0017] Substance: A chemical product that cannot be separated into its components by physical separation (ie, chemical bonds cannot be broken), such as compounds, alloys, or elemental substances, but does not include mixtures.

[0018] The reduction in reactivity of nuclear reactions may be for the purpose of temporarily controlling reactivity, eg to compensate for the desired reduction in initial high reactivity as fission proceeds, and for the purpose of total cessation of reactivity.

[0019] This can be achieved by adding neutron absorbing material to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com