Polydextrose-containing steak and preparation method thereof

A technology for polydextrose and steak is applied in the field of polydextrose-added steak and its preparation, and achieves the effects of easy popularization and application, reasonable supplement of dietary fiber, and improved uniformity of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

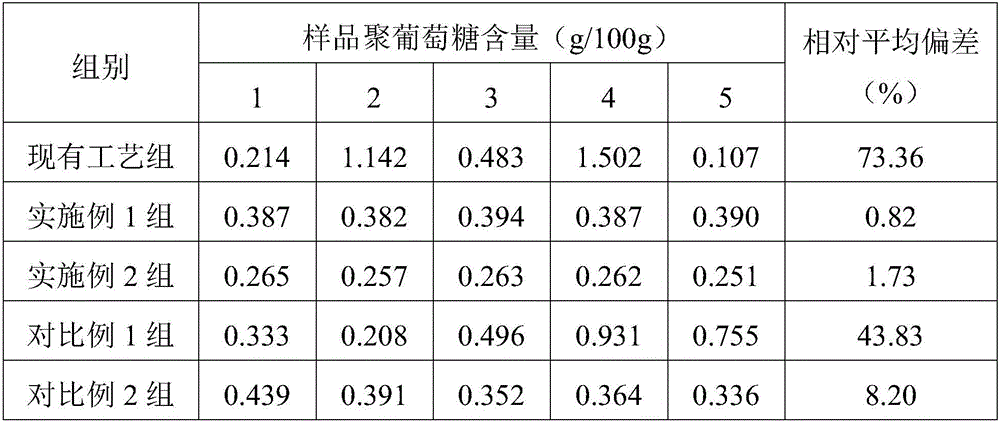

Examples

Embodiment 1

[0058] A kind of steak added with polydextrose, the steak is made from the following raw materials in parts by weight:

[0059] Beef tenderloin 100; table salt 1.3; white sugar 0.5; phosphate 0.5;

[0060] Protein Isolate 2.0; Starch 3.0; Polydextrose 0.6; Spice 0.15;

[0061] Black pepper 1.0; Monosodium glutamate 0.5; Flavor 0.10; Ice water 42;

[0062] Transglutaminase 0.20.

[0063] The preparation method is as follows:

[0064] (1) Thawing: thaw the beef tenderloin, control the temperature of the thawing room at 8-12°C, and the thawing time is 24-36h, and the temperature of the center of the meat after thawing is 0-2°C;

[0065] (2) Segmentation: remove fat and fascia from the thawed beef tenderloin, and divide it longitudinally into 0.8-1kg blocks for later use. The temperature of the segmentation chamber is 0-4°C, and the segmentation time shall not exceed 2 hours;

[0066] (3) Preparation of feed liquid: mix salt, white sugar, phosphate, protein isolate, starch, po...

Embodiment 2

[0074] A kind of steak added with polydextrose, the steak is made from the following raw materials in parts by weight:

[0075] Beef tenderloin 80; table salt 1.0; white sugar 0.2; phosphate 0.3;

[0076] Protein Isolate 1.5; Starch 2.0; Polydextrose 0.3; Spice 0.10;

[0077] Black pepper 0.8; Monosodium glutamate 0.3; Flavor 0.05; Ice water 32;

[0078] Transglutaminase 0.15.

[0079] The preparation method is as follows:

[0080] (1) Thawing: thaw the beef tenderloin, control the temperature of the thawing room at 8-12°C, and the thawing time is 24-36h, and the temperature of the center of the meat after thawing is 0-2°C;

[0081] (2) Segmentation: remove fat and fascia from the thawed beef tenderloin, and divide it longitudinally into 0.8-1kg blocks for later use. The temperature of the segmentation chamber is 0-4°C, and the segmentation time shall not exceed 2 hours;

[0082] (3) Preparation of feed liquid: mix salt, white sugar, phosphate, protein isolate, starch, pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com