Method for preparing sludge derived fuel RDF, bio-organic fertilizer and inorganic building materials with garbage served as raw material

A bio-organic fertilizer and derived fuel technology, applied in the field of bio-organic fertilizers and inorganic building materials, can solve problems such as high content of perishable substances, increased product production costs, and environmental protection projects that are not environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

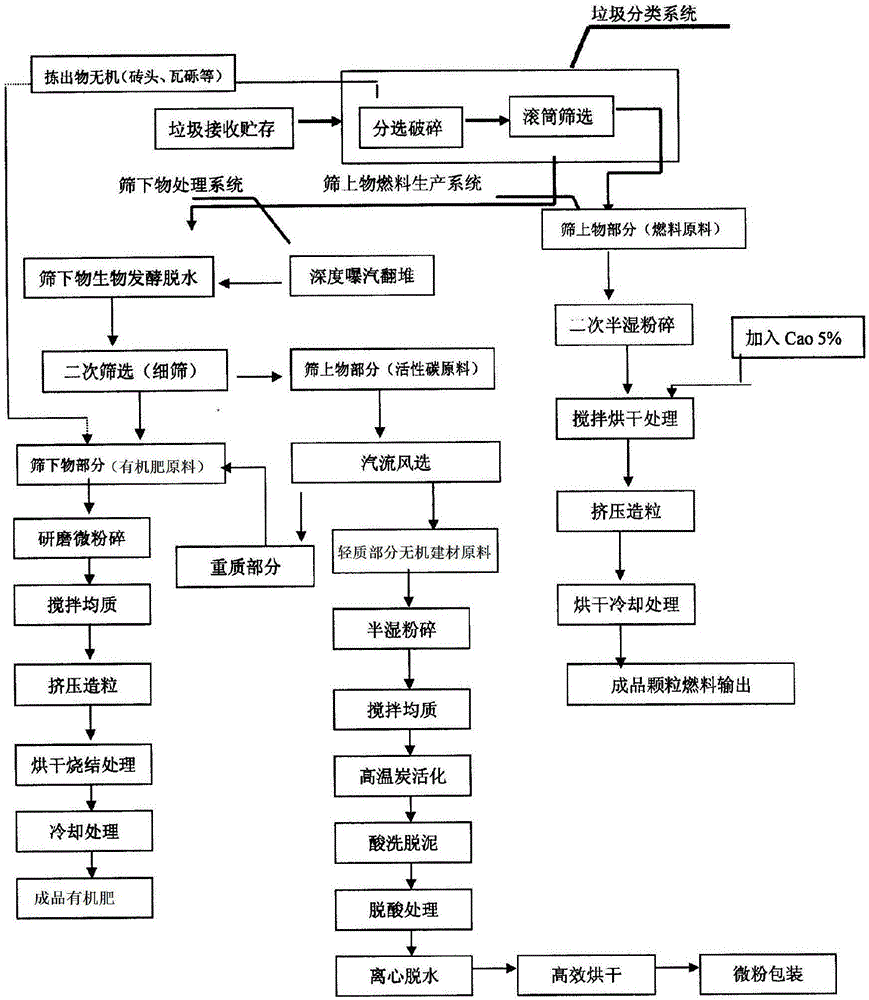

[0090] Embodiment 1: the method for preparing derivative fuel RDF, bio-organic fertilizer and inorganic building materials with rubbish as raw material, comprises the following steps:

[0091] 1. Garbage sorting and crushing: Effective mechanized sorting and crushing of high-humidity mixed urban waste, ensuring bag breaking rate ≥ 95%, output block size ≤ 100mm, automatic sorting out bricks, rubble, metal, batteries Hard materials such as leather goods, clothes and other large items, among which leather goods, clothes and other large items are returned to the system for secondary crushing after large-scale crushing;

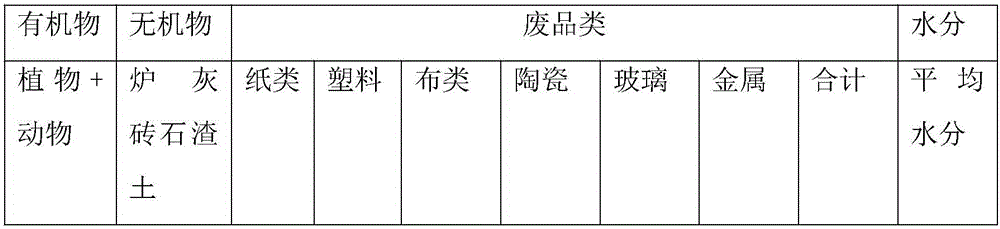

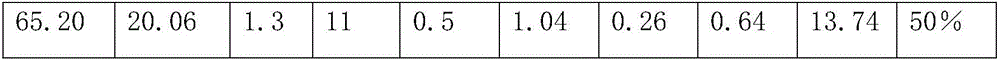

[0092] 2. Drum screening: It is the process of screening the remaining broken garbage with a water content of 50% after sorting and crushing in a special drum sieve. It classifies the garbage into two parts: the oversize and the undersize. The typical composition of the upper object is:

[0093] The typical ingredient list (table four, unit: weight %) of the sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com