Apparatus For Deriving Natural Frequency Of Cutting Tool

A technology of inherent vibration and cutting tools, applied in manufacturing tools, measuring devices, program control, etc., can solve the problems of poor machining accuracy and surface accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

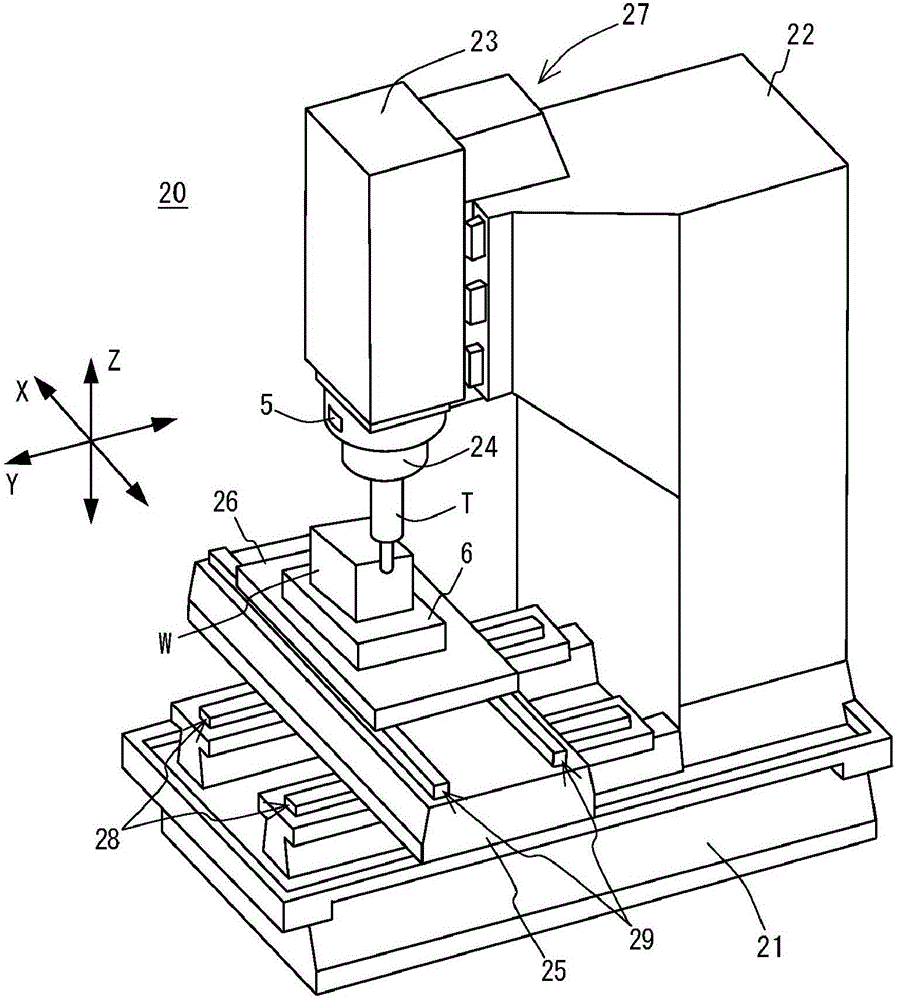

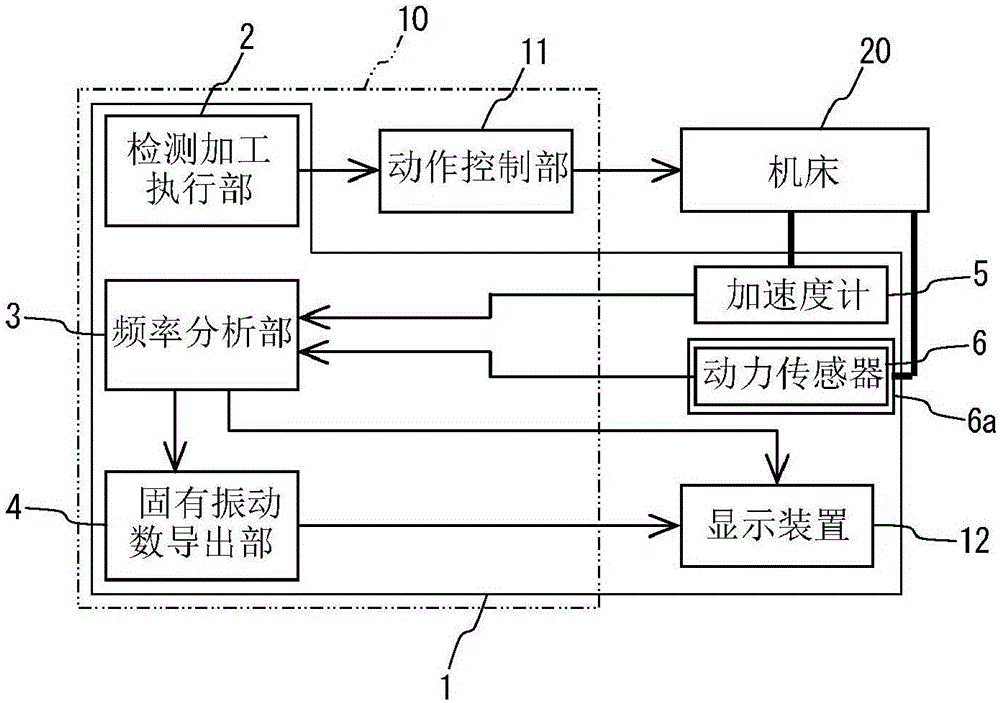

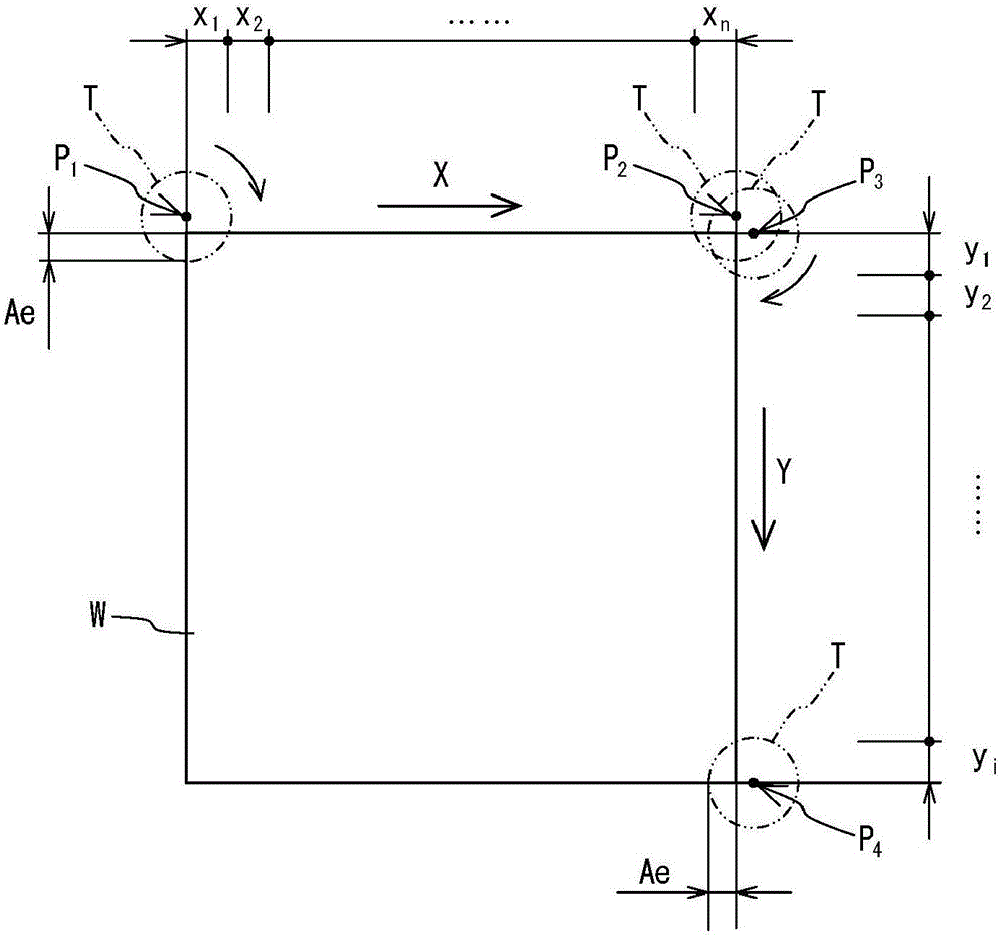

[0074] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. figure 1 is a perspective view showing a machine tool used in this embodiment, figure 2 It is a block diagram showing the natural frequency derivation device and the like of the present embodiment.

[0075] [Outline configuration of machine tool]

[0076]First, the schematic configuration of the machine tool 20 will be described. This machine tool 20 is provided with: a base (bed) 21; a column 22, which is erected on the base 21; surface); the main shaft 24 is freely rotatably held on the main shaft head 23 along the shaft center; On the base 21; the workbench 26 is freely movable on the saddle 25 in the X-axis direction shown by the arrow; the X-axis feed mechanism 29 makes the workbench 26 move on the X-axis (the first axis) ) direction; the Y-axis feed mechanism 28 makes the saddle 25 move in the direction of the Y-axis (second axis); the Z-axis feed mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com