Tar treatment method and treatment device

The technology of a processing device and a processing method is applied in the processing of tar, the processing of tar by heat treatment, the petroleum industry, etc., and can solve the problems of high energy consumption, inability to transport, and the inability to transport coal tar over long distances in the pipeline, and achieve The effect of saving energy, avoiding the release of harmful substances, and safe disposal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

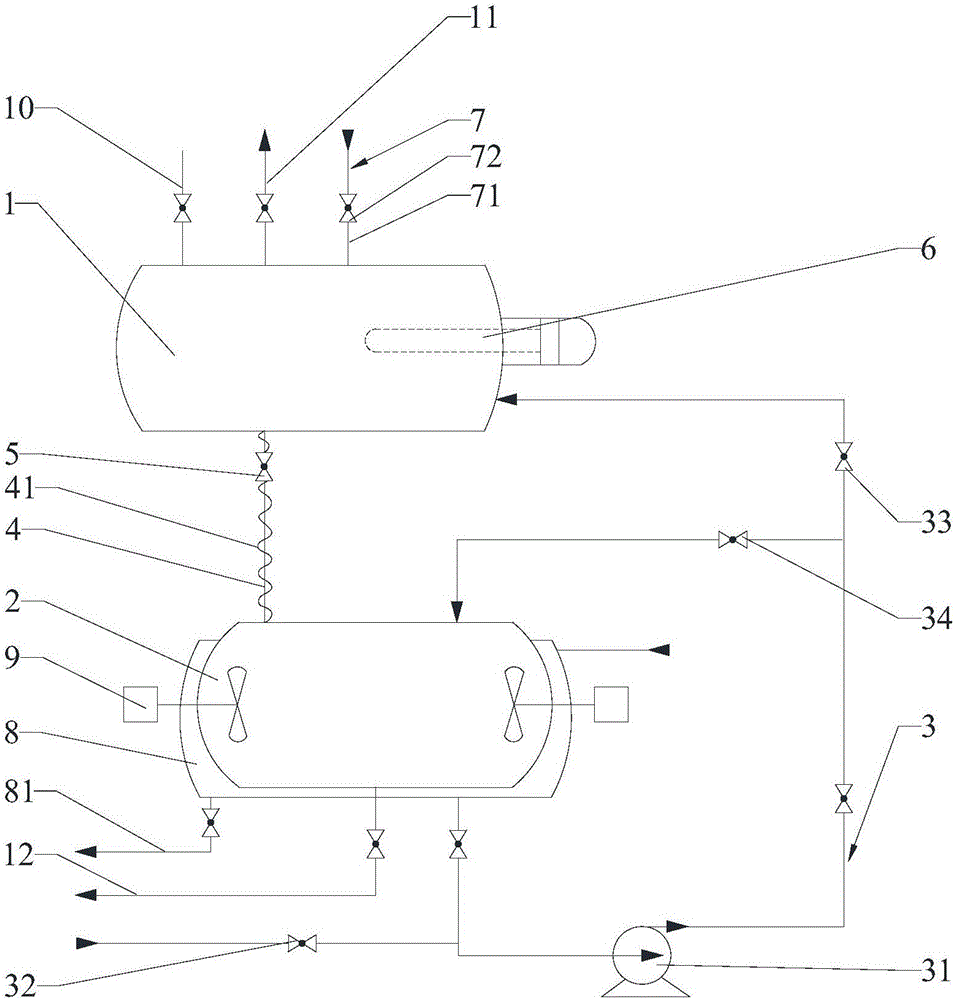

[0045] Please refer to figure 1 Shown, embodiment one of the present invention is:

[0046] Tar processing method provided by the invention comprises the steps:

[0047] Step 1: Heat the DMF circulating solvent containing tar to 140°C in a closed environment, and adjust the pressure to -0.075MPa by vacuuming. Under negative pressure, the DMF solvent becomes a gas and is separated to obtain the separated tar , and keep the temperature of the tar at 140° C.; when the content of the tar-containing DMF circulating solvent in the tar is as low as 8%, stop the extraction, and feed nitrogen to adjust the pressure to 0.1 MPa at normal pressure.

[0048] Step 2: Heat the ethylene pan oil to 130°C in a closed environment;

[0049] Step 3: Transport the tar separated in step 1 with a temperature of 120°C to 150°C into the closed environment of step 2. The temperature of the ethylene pan oil is kept at 125°C to 135°C. The tar is continuously heated during the transportation process, and...

Embodiment 2

[0051] Please refer to figure 1 Shown, embodiment two of the present invention is:

[0052] On the basis of Embodiment 1, the tar oil treatment device is further improved. The heating device on the first container 1 is a heating coil 6, and the heating coil 6 is arranged inside the first container 1. The first The heating device on the second container 2 is a steam heating jacket 8, and the steam heating jacket 8 is provided with a condensed water pipe 81. The delivery system 3 includes a delivery pump 31 and a delivery pipeline, and the delivery pump 31 is arranged on the delivery pipeline. Above, the delivery pipeline at the front end of the delivery pump 31 is provided with a second valve 32, and the delivery pump 31 is respectively connected to the first container 1 and the second container 2 through the delivery pipeline, and the connection between the delivery pump 31 and the first container A third valve 33 is provided on the delivery pipeline, and a fourth valve 34 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com