Refining and separating device for wood vinegar

A separation device and technology of wood vinegar, which is applied in the refining and separation device of wood vinegar, and in the field of wood vinegar refining and separation from biomass, can solve the problems that soluble impurities cannot be removed and affect the quality of wood vinegar, and achieve quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

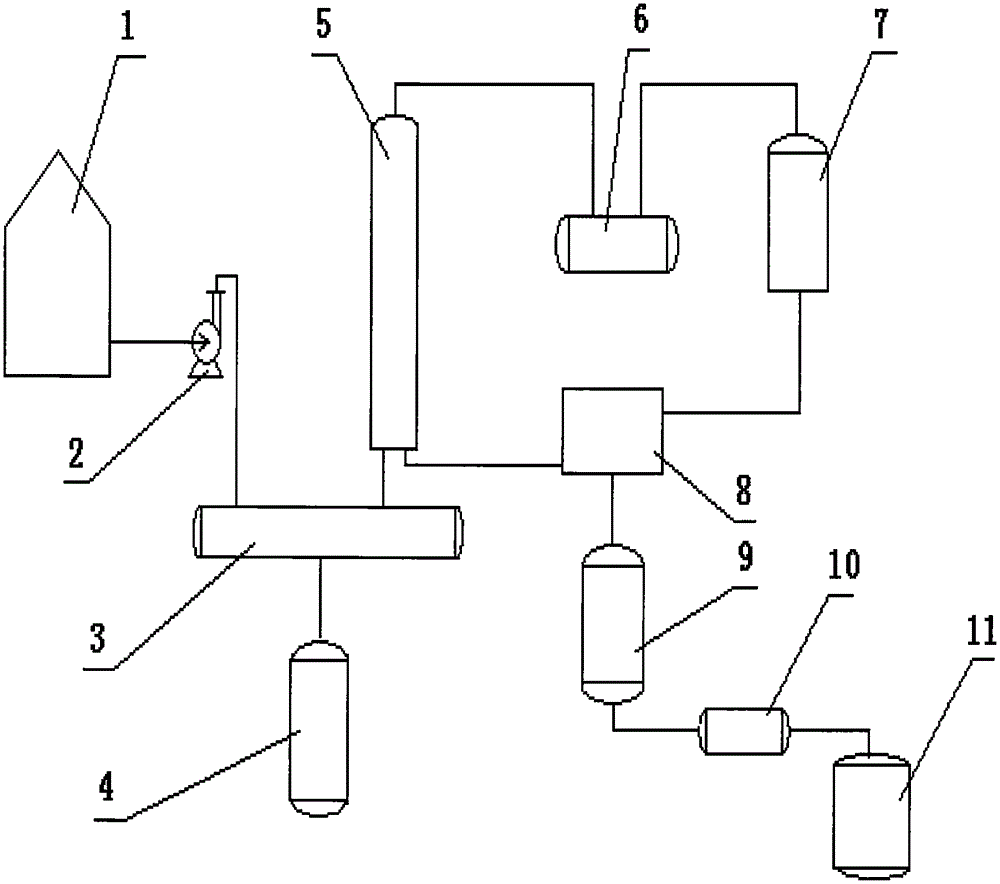

[0011] see figure 1 , through the description of the embodiments, the specific implementation of the present invention, such as the relationship between the various parts involved, the role and working principle of each part, and the method of operation and use, etc., will be further described in detail to help engineering in this field. The technical personnel have a more complete, accurate and in-depth understanding of the concept of the present invention and the technical solution.

[0012] The refining and separating device of wood vinegar of the present invention comprises a raw material storage tank 1, a raw material pump 2, a still 3, a bottom tar storage tank 4, a rectifying tower 5, a condenser 6, a reflux tank 7, a reflux pump 8, and a distillate tank 9. Adsorption device 10, finished product tank 11.

[0013] The raw material storage tank 1 is a container for storing crude wood vinegar.

[0014] Its effect of described raw material pump 2 is that crude wood vinega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com