Horizontal opposed engine

A horizontally opposed engine technology, which is applied in the direction of machines/engines, mechanical equipment, transmissions, etc., can solve the problems of incomplete valve closure, unequal lateral force, unequal cylinder pressure, etc., to achieve simplified design requirements and offset impact The effect of low power and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

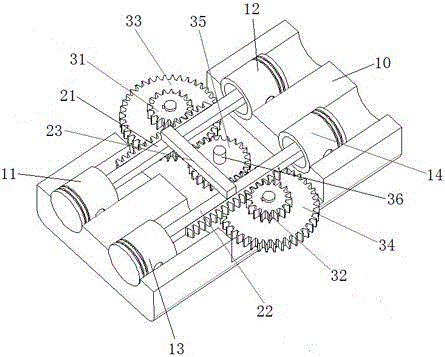

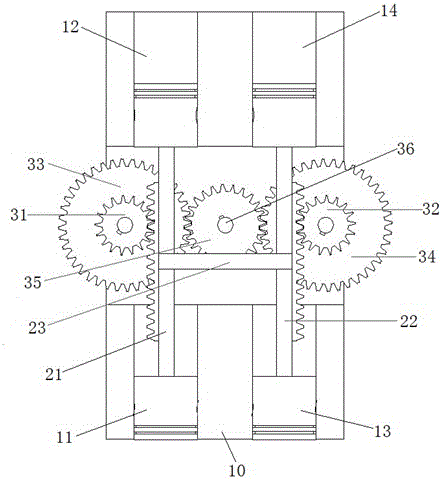

[0022] A horizontally opposed engine, including cylinder heads, intake ducts, exhaust ducts, fuel injectors, cylinder blocks, cylinder liners and pistons. Such as figure 1 with figure 2 As shown, for the sake of simplicity, only the cylinder, piston, transmission and power output are shown in the figure, and the rest are omitted.

[0023] As shown in the figure, a horizontally opposed engine has a cylinder block 10 with four horizontally opposed cylinders, and the four cylinders are respectively provided with a piston 11, a piston 2 12, a piston 3 13 and a piston 4 14 therein. It also includes a connecting rod assembly and a gear transmission mechanism, wherein the connecting rod assembly includes a connecting rod 21 and a connecting rod 22. The two ends of the connecting rod 21 are connected to the piston 11 and the piston 12 through a piston pin. The two ends of 22 are respectively connected with piston three 13 and piston four 14 through piston pins. In order to further imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com