Propeller Direction Guidance Controller

A technology of a propulsion machine and a controller is applied in the field of the direction guidance controller of the propelling machine, which can solve the problems of inconvenience of maintenance personnel, short circuit of circuit boards, easy access to water, etc., and achieve the effects of reducing errors, reducing volume and improving space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

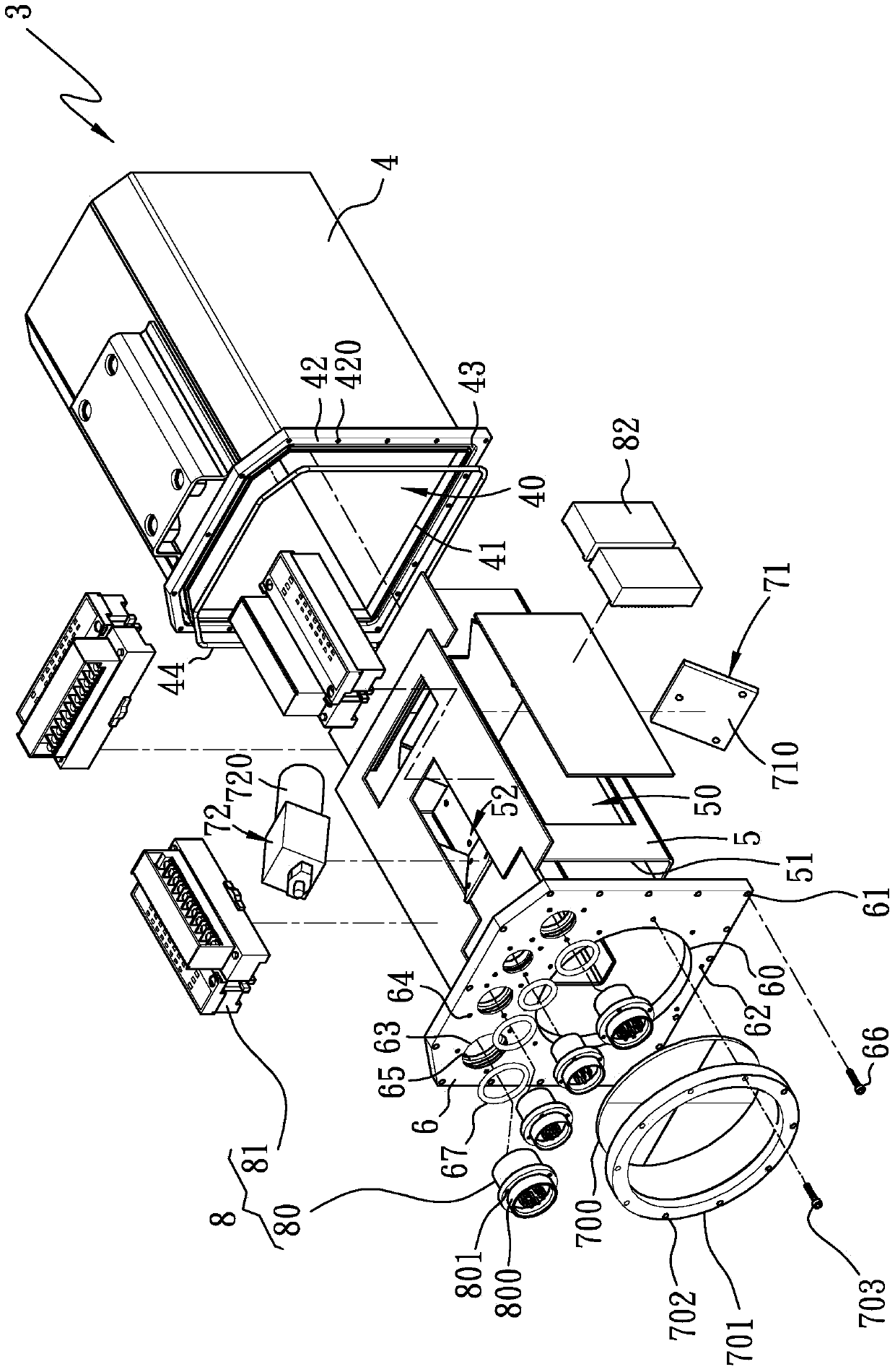

[0067] The following describes in detail how the structure of the present invention is combined and used in conjunction with the attached diagrams, and it should be easier to understand the purpose, technical content, characteristics and effects of the present invention.

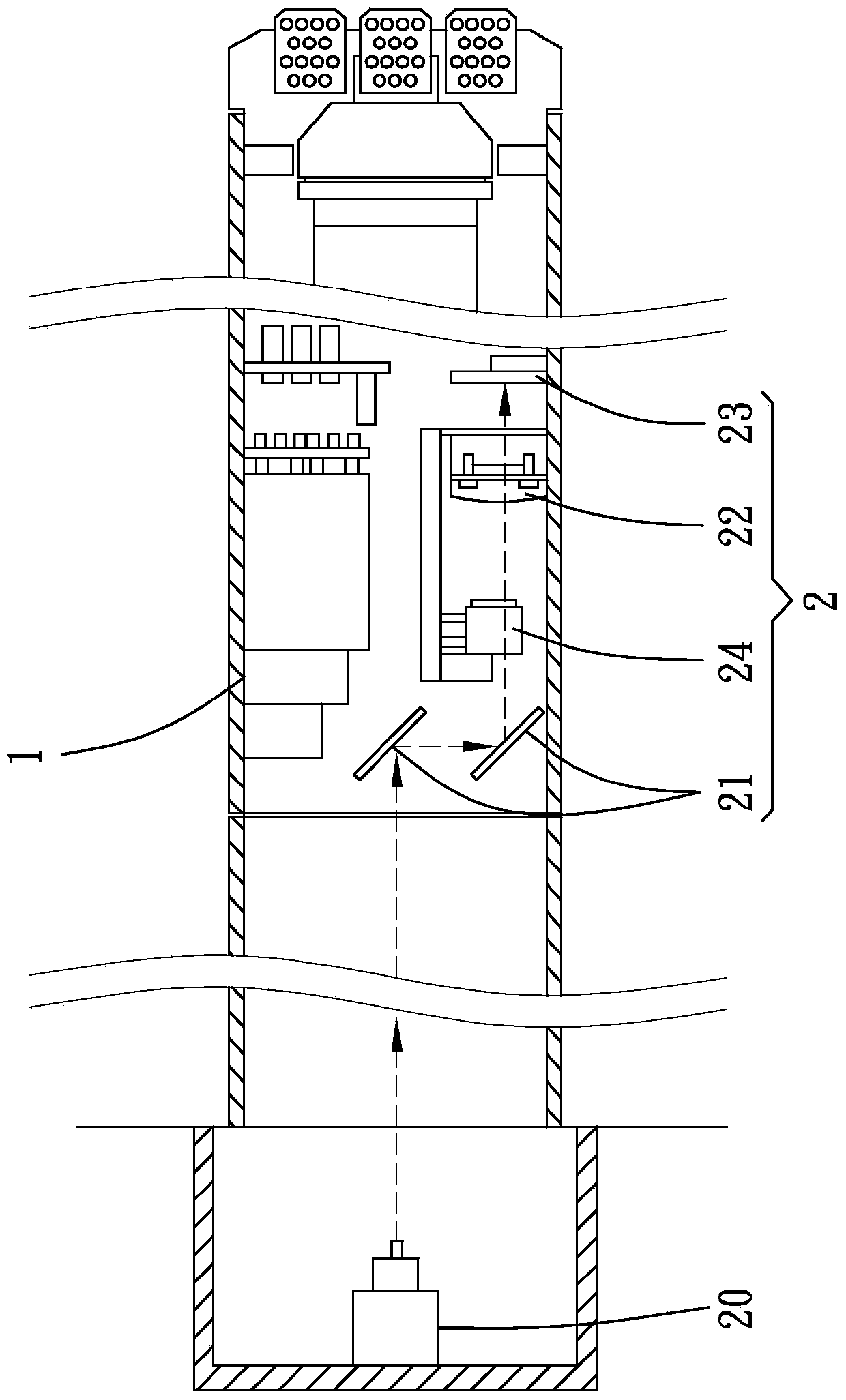

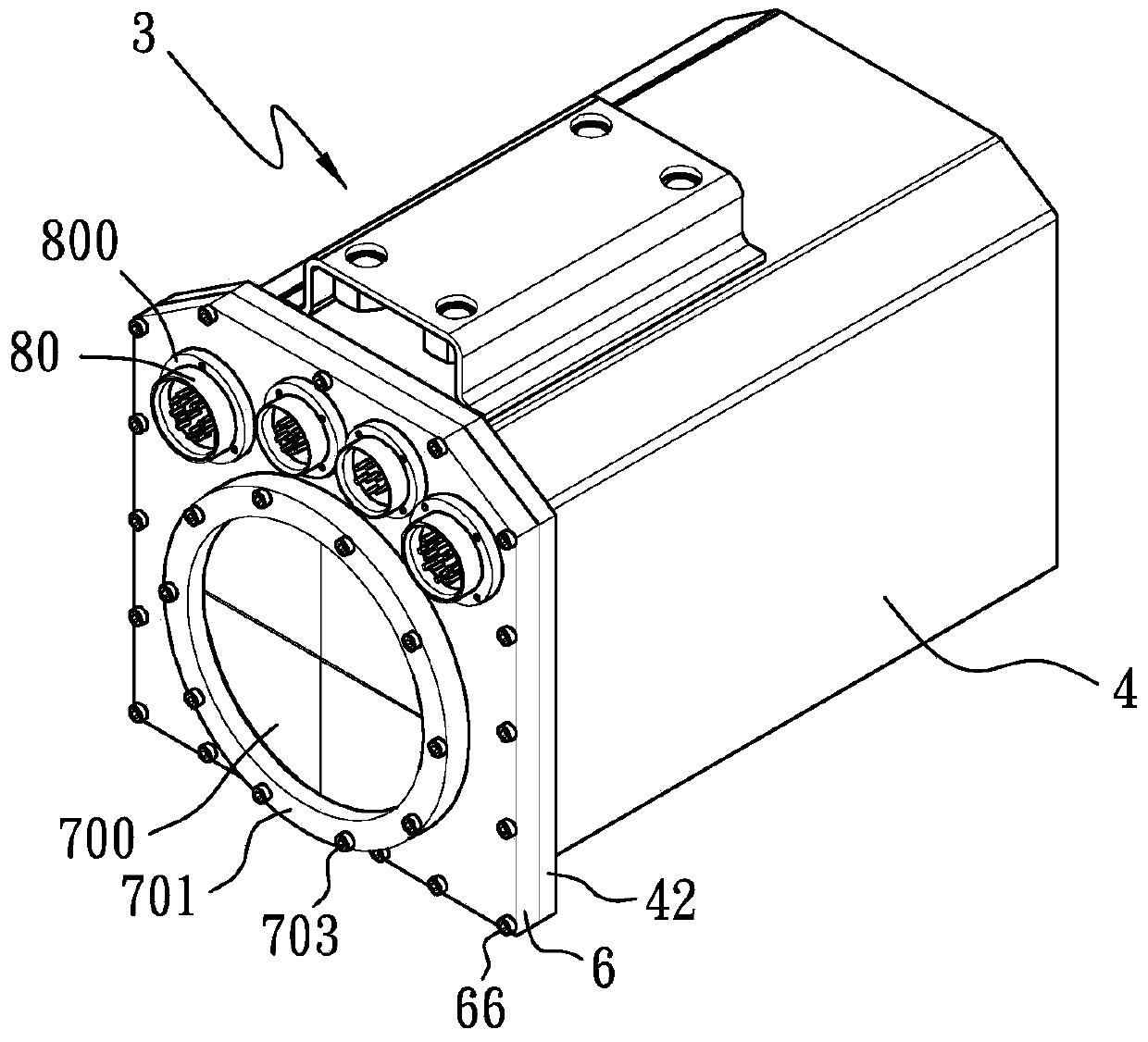

[0068] see Figure 2 to Figure 4 As shown, a thruster direction guidance controller 3 proposed by the present invention is applied to a thruster 9, and through the thruster direction guidance controller 3, it can be judged whether the thruster 9 deviates during the excavation process. Phenomenon and by a correction tool (not shown in the figure), guide the propelling machine 9 back to the correct direction to improve the construction quality. Wherein, the propulsion machine direction guidance controller 3 includes a box 4 , a cover 6 , a display unit 7 , and a control unit 8 .

[0069] The box body 4 includes an accommodating space 40 inside the box body 4, an opening 41 opened at one end of the box body 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com