Photoresistor ceramics and preparation method

A technology of photosensitive resistors and ceramics, which is applied in the manufacture of circuits, electrical components, and final products, and can solve problems such as poor stability and reduced performance parameters of photosensitive resistor ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

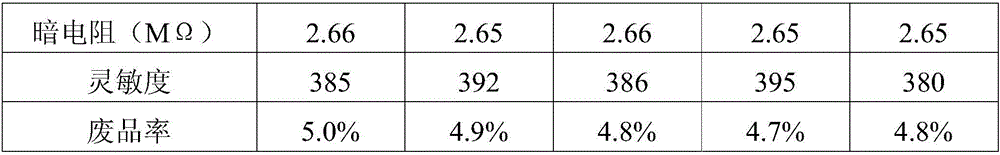

Examples

Embodiment 1

[0019] This embodiment provides a kind of photoresistor porcelain, which is made of the following components by weight: 60 parts of CdS, 30 parts of CdSe, CdCl 2 2.8 parts, ZnCl 2 3.5 parts, CuCl 2 3.5 parts, LiCl 2 2 parts of Cu(NO 3 ) 2 1 part of solution.

[0020] The preparation method of the photoresistor ceramic of the present embodiment comprises the following steps:

[0021] (1) Take CdSe and burn it at 450°C for 6 hours in a nitrogen atmosphere, then grind it with deionized water, and dry it for later use;

[0022] (2) Take CdS, CdCl 2 , ZnCl 2 , CuCl 2 , LiCl 2 Dry the standby CdSe in step (1), add deionized and grind to mix evenly, then add Cu(NO 3 ) 2 Grind evenly;

[0023] (3) Spray the above mixed solution on the substrate with a spray gun, spray the film, dry, put it into a tube furnace for firing, and obtain it. The firing is carried out at 600° C. for 40 minutes in a nitrogen atmosphere. The step (3) further includes the step of spraying an e...

Embodiment 2

[0025] This embodiment provides a kind of photoresistor porcelain, which is made of the following components by weight: 50 parts of CdS, 35 parts of CdSe, CdCl 2 2 parts, ZnCl 2 4 parts, CuCl 2 3 parts, LiCl 2 3.5 parts of Cu(NO 3 ) 2 0.5 parts by weight of the solution.

[0026] The preparation method of the photoresistor ceramic of the present embodiment comprises the following steps:

[0027] (1) Take CdSe and burn it at 400°C for 7 hours in a nitrogen atmosphere, then grind it with deionized water, and dry it for later use;

[0028] (2) Take CdS, CdCl 2 , ZnCl 2 , CuCl 2 , LiCl 2 Dry the standby CdSe in step (1), add deionized and grind to mix evenly, then add Cu(NO 3 ) 2 Grind evenly;

[0029] (3) Spray the above mixed solution on the substrate with a spray gun, spray the film, dry, put it into a tube furnace for firing, and obtain it. The firing is carried out at 600° C. for 30 minutes in a nitrogen atmosphere. The step (3) further includes the step of ...

Embodiment 3

[0031] This embodiment provides a kind of photoresistor porcelain, which is made of the following components by weight: 70 parts of CdS, 20 parts of CdSe, CdCl 2 3.5 parts, ZnCl 2 2.5 parts, CuCl 2 4 parts, LiCl 2 1 part, Cu(NO 3 ) 2 1.5 parts by weight of the solution.

[0032] The preparation method of the photoresistor ceramic of the present embodiment comprises the following steps:

[0033] (1) Take CdSe and burn it at 500°C for 5 hours in a nitrogen atmosphere, then grind it with deionized water, and dry it for later use;

[0034] (2) Take CdS, CdCl 2 , ZnCl 2 , CuCl 2 , LiCl 2 Dry the standby CdSe in step (1), add deionized and grind to mix evenly, then add Cu(NO 3 ) 2 Grind evenly;

[0035] (3) Spray the above mixed solution on the substrate with a spray gun, spray the film, dry, put it into a tube furnace for firing, and obtain it. The firing is carried out at 600° C. for 45 minutes in a nitrogen atmosphere. The step (3) further includes the step of spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com