Efficient chip LED packaging structure

A technology of LED packaging and LED brackets, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of excessive operating current and short life of SMD packaging, and achieve improved brightness, long life, and slow aging speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

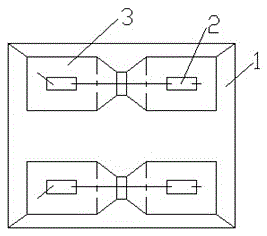

[0009] figure 1 It is a top view of a high-efficiency patch LED packaging structure provided by the present invention, including an LED bracket 1, an LED chip 2 arranged in the bracket 1, the LED bracket 1 to which it belongs is designed with an inverted trapezoidal groove 3, and chips 2 (4 pieces chips) are respectively placed in four independent bowls, and the bowls are designed to be concave on both sides and slightly convex in the middle, the walls of the four grooves are all designed as inverted trapezoids, and the front surfaces of the bottom bowls of the four grooves are all The silver-plated layer is used to place 4 chips. The slightly protruding part in the middle of the four bowls is the PPA layer. The walls of the bowls have a certain gradient to increase the angle of light; and the back of each groove at the bottom of the bracket is Desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com