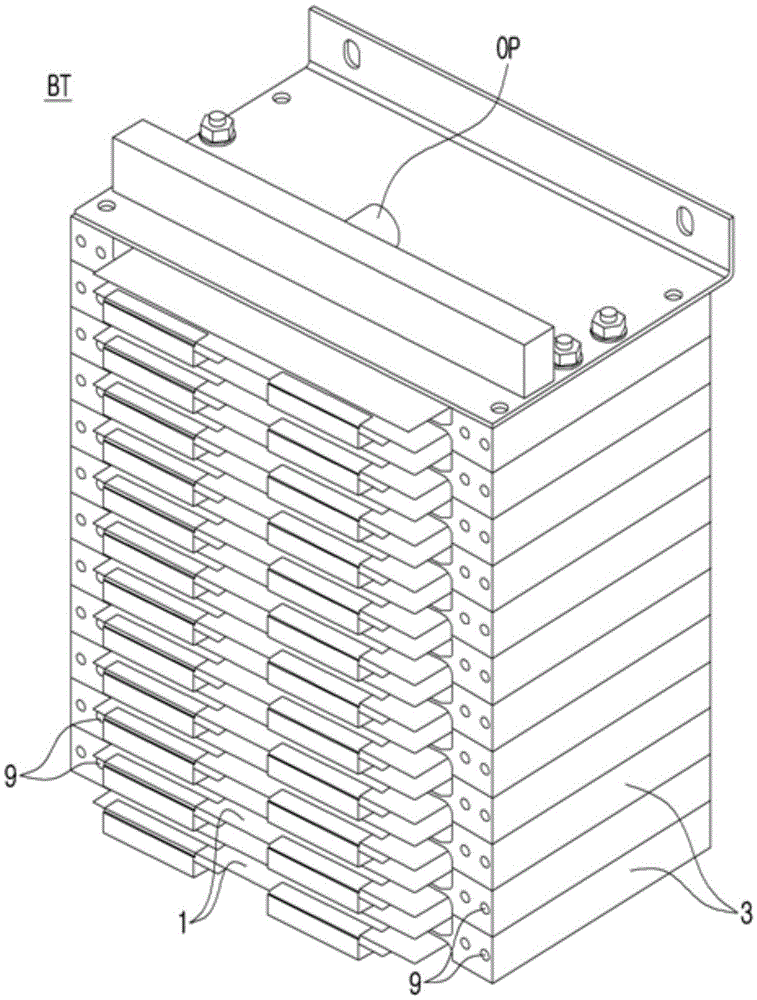

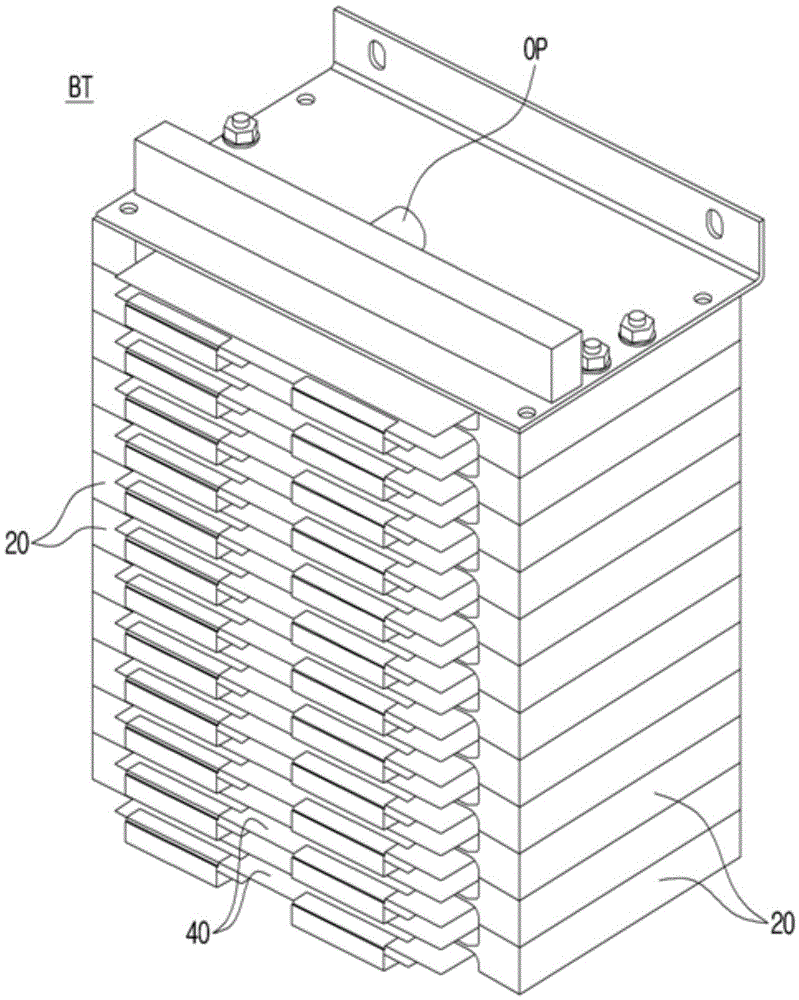

Heat exchanger for battery

A heat exchanger and battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of increasing assembly processes, increasing the overall manufacturing cost of battery heat exchangers, and manufacturing difficulties, and achieves improved cooling performance, increased obstacles, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

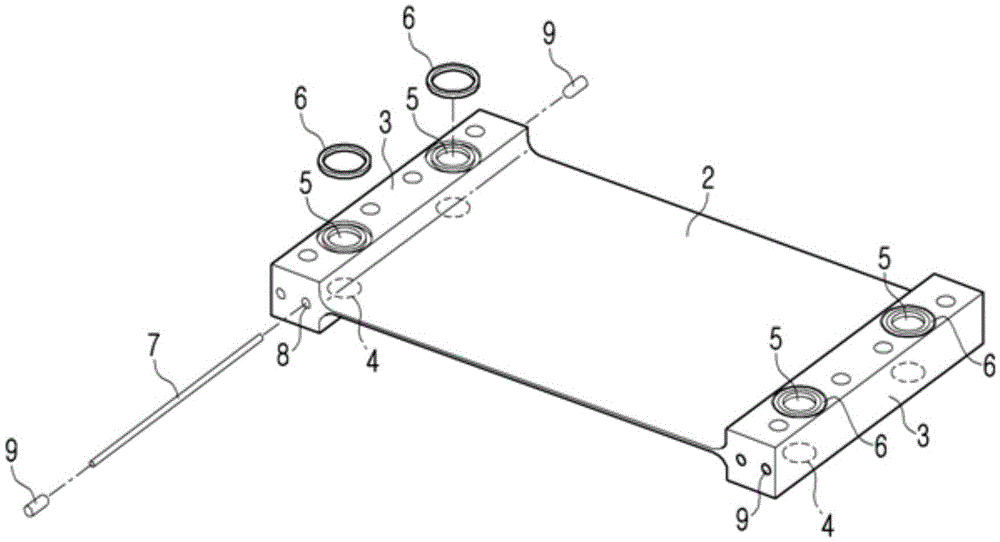

[0070] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0071] However, the size and thickness of each constituent element shown in the drawings are arbitrarily shown for convenience of description, so the present invention is not necessarily limited to those shown in the drawings, and the size and thickness of each component and region are enlarged in order to clearly show each part and region. out of thickness. In addition, in order to clearly describe the embodiments of the present invention, parts irrelevant to the description have been deleted, and the description has been given by assigning the same reference numerals to the same or similar components throughout the entire specification. In addition, when it is stated that a certain component includes a certain component in the entire content of the specification, unless there is a particularly objectionable description, it does not mean that other components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com