Electric connector female terminal and processing method thereof

An electrical connector and processing method technology, applied in the field of electrical connector female terminals and their processing, can solve the problems of easy deformation and damage repair of products, high manufacturing and labor costs, complex manufacturing processes, etc., and achieve easy application and popularization. Simple manufacturing process and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

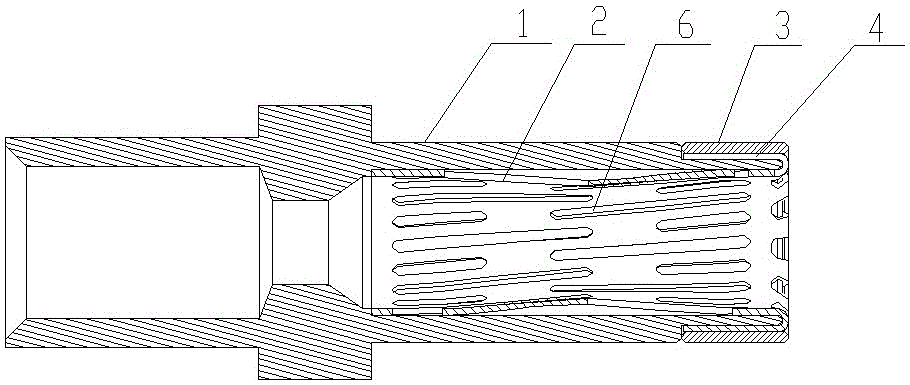

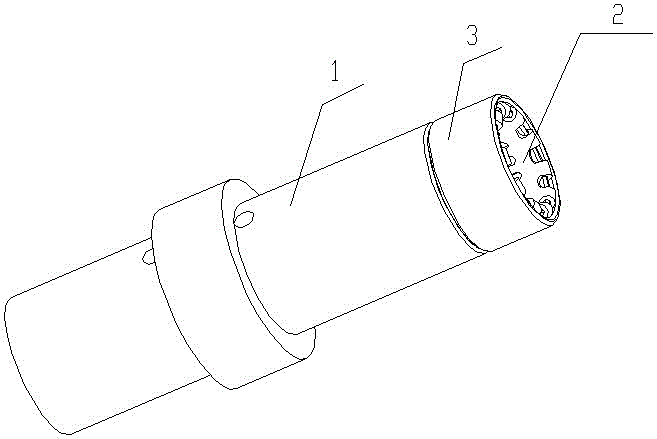

[0021] See attached figure 1 ~ attached figure 2 , the present invention is composed of a sleeve 1, a female terminal 2 and an outer sleeve 3, the female terminal 2 is assembled in the sleeve 1, and its several fixing claws 4 are folded outward on the outer edge of one end of the sleeve 1 and It is crimped and fixed by the outer sleeve 3 .

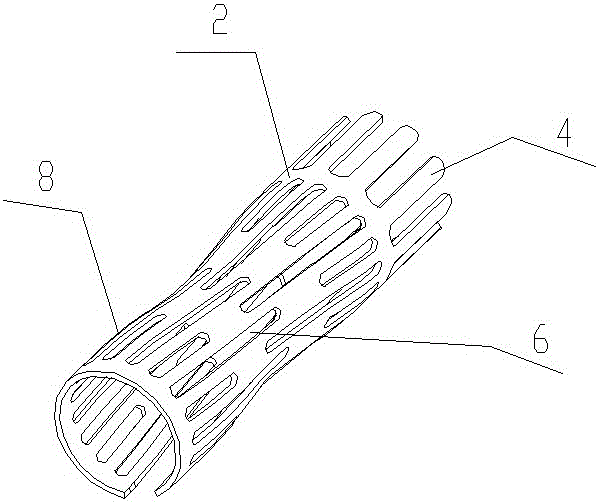

[0022] See attached image 3 , the female terminal 2 is an elastic cylinder with several parallel and interlaced reeds 6 and a wave structure 8 in the axial direction, and several fixed claws 4 are provided at one end, and the interlaced reeds 6 are each spring The slices 6 are arranged axially successively and interlaced with each other.

[0023] See attached Figure 4 , making, installation of the present invention comprises the following steps:

[0024] See attached Figure 4 In Figures a and b, the conductive metal sheet is cut into a parallelogram blank 21 according to the design requirements for stamping, so that it forms a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com