Dry material wet feeding method and system

A dry and wet feeding technology, applied in the field of dry and wet feeding methods and systems, achieves the effects of saving water consumption, improving economic benefits, and simple technology and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

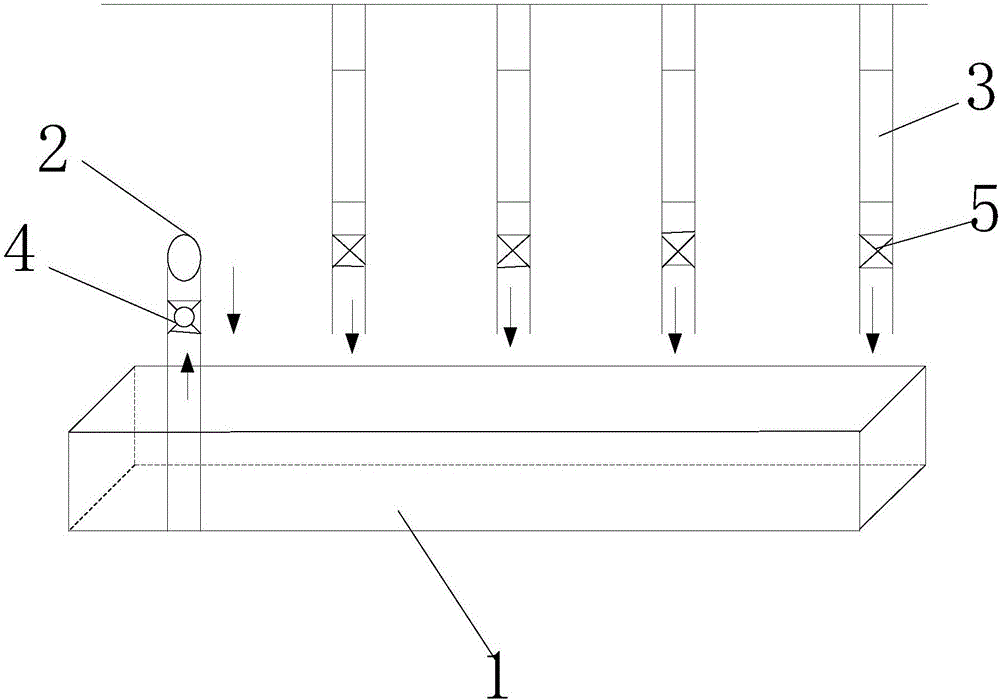

[0025] The application principle of the present invention will be described in detail below with reference to the accompanying drawings.

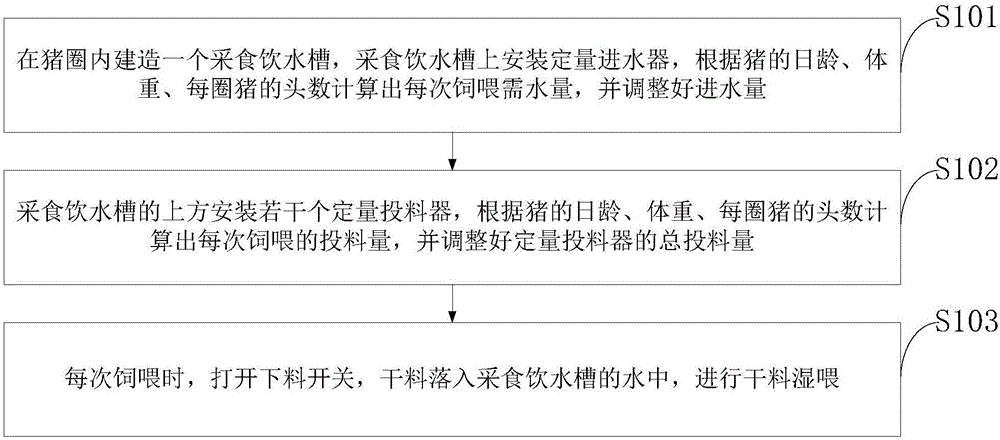

[0026] Such as figure 1 As shown, the dry material wet feeding method provided by the embodiment of the present invention includes:

[0027] S101: Build a feeding and drinking trough in the pigpen, install a quantitative water inlet on the feeding and drinking trough, calculate the water requirement for each feeding according to the age, weight, and the number of pigs in each pen, and adjust it well Water intake.

[0028] S102: Install a number of quantitative feeders above the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com