A method for efficiently crushing and separating eggshells and shell membranes of poultry breeding eggs after hatching

A separation method and high-efficiency pulverization technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc. It can improve the disease resistance of livestock and poultry, reduce the occurrence of respiratory diseases, and reduce the rate of broken eggs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

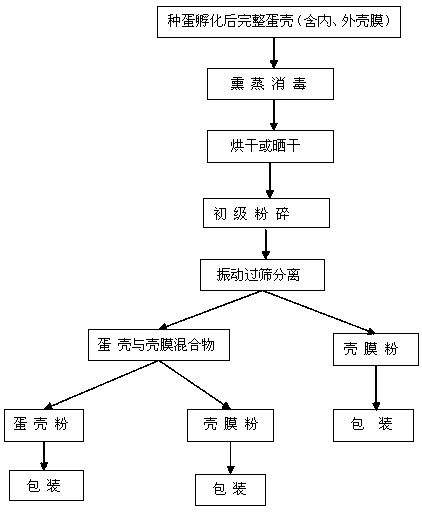

Image

Examples

Embodiment 1

[0025] A hatchery A has been hatching and supplying a variety of chicks for many years. The annual emergence is about 3 million chicks, and the eggshells produced after hatching are about 17 tons. Due to the random stacking of eggshells in residential areas, it has caused great environmental pollution. In June 2015, the present invention was used to separate eggshells and shell membranes. The method is as follows:

[0026] a. After picking out the hatching chicks, place the hatching tray with egg shells on the hatching frame, push it into the hatching machine and press formalin (48ml / m 3 ) + potassium permanganate (24g / m 3 ) closed fumigation for 24 hours.

[0027] b. After disinfection, take it out and spread it on the cement floor to dry for one day, or keep it in the hatcher for ventilation, and then use the incubation setting temperature of 40°C to dry for 16 hours.

[0028] c. Utilize the 9ZF-50 chaff crushing and kneading machine (aperture of the sieve bottom: 8.0mm), ...

Embodiment 2

[0032] Certain poultry limited liability company B raises 20,000 sets of laying hens every year, with an annual output of about 30 tons of intact eggshells after hatching. In order to deal with the problem of hatching eggshells and affect normal production. In February 2015, it was recommended to use the eggshell and shell membrane separation method of the present invention, the method is as follows:

[0033] a. After picking out the hatching chicks, place the hatching tray with eggshells on the hatching frame, push it into the special fumigation and disinfection room and press formalin (40ml / m 3 ) + potassium permanganate (20g / m 3 ) closed fumigation for 24 hours.

[0034] b. After disinfection, push the egg rack trolley into the hatcher, and set the temperature for incubation at 50°C to dry for 12 hours.

[0035]c. Pour the eggshells into the ground groove and use the spiral lift to force feed the material into the hammer mill (the aperture of the sieve bottom is 8.0mm). ...

Embodiment 3

[0039] A certain duck hatchery C raises 10,000 sets of laying ducks all the year round, and the annual eggshell output is about 16 tons. In order to completely change the pollution to the environment caused by eggshell stacking, in August 2015, the eggshell and shell membrane separation method of the present invention was carried out:

[0040] a. After picking out the hatched ducklings, put the hatching tray with eggshells into the airtight disinfection room, press formalin (44ml / m 3 ) + potassium permanganate (22g / m 3 ) closed fumigation for 24 hours.

[0041] b. After disinfection, take it out and spread it on the cement floor to dry for one day, or put it into the hatcher, and set the temperature for 14 hours at 45°C for incubation.

[0042] c. After drying, use a hammer-type feed mill (screen bottom aperture: 8.0mm), pour eggshells from the feed port for primary crushing,

[0043] d. The primary crushed material is vibrated and screened by a multifunctional grain screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com