Lollipop and production die and method thereof

A lollipop and mold technology, applied in confectionery, confectionery industry, cocoa, etc., can solve the problems of high sugar content and high sugar content in lollipops, and achieve the effect of uniform texture, convenient operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

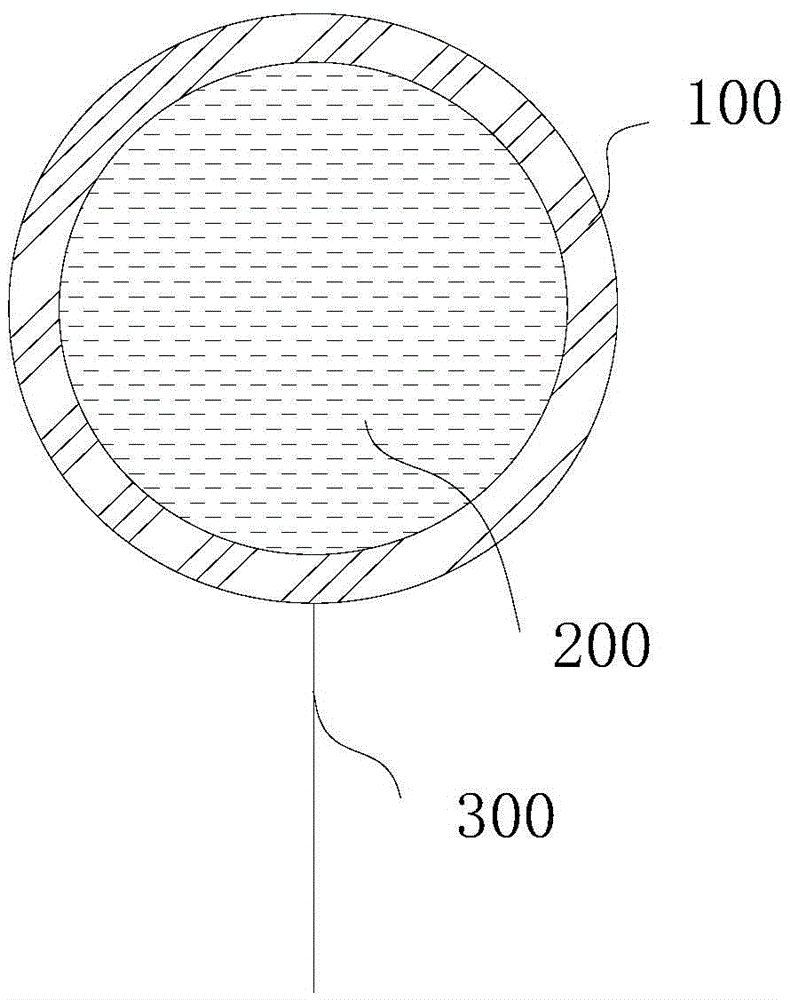

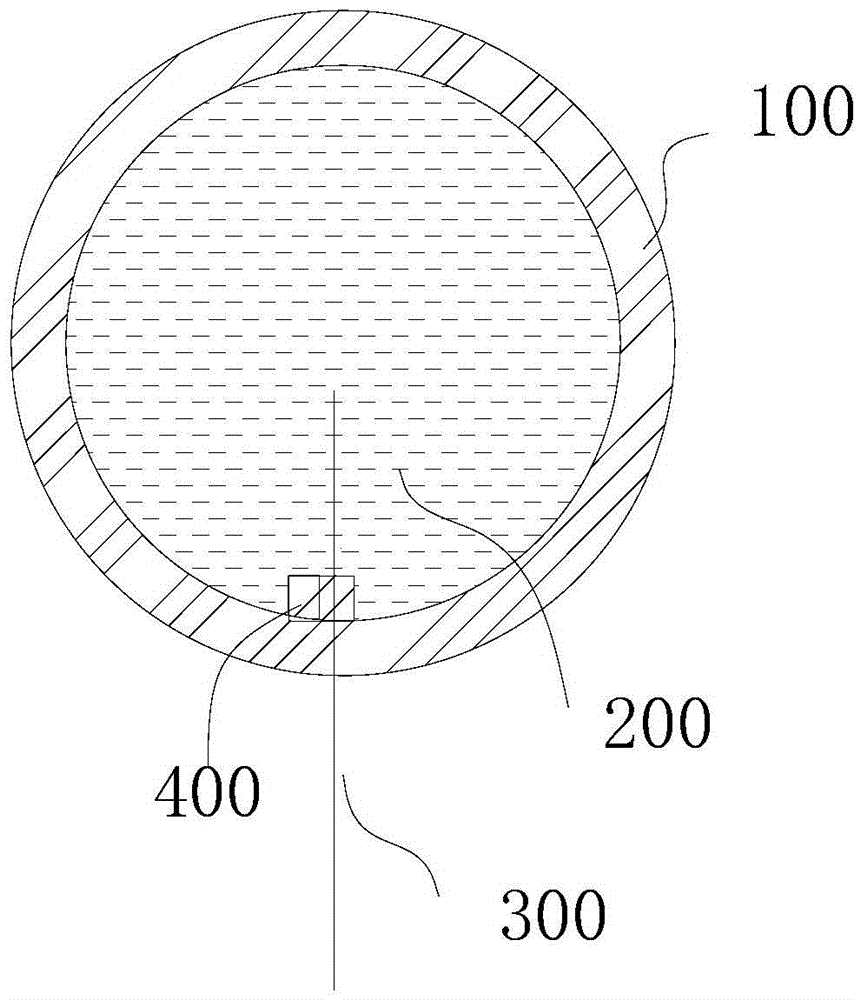

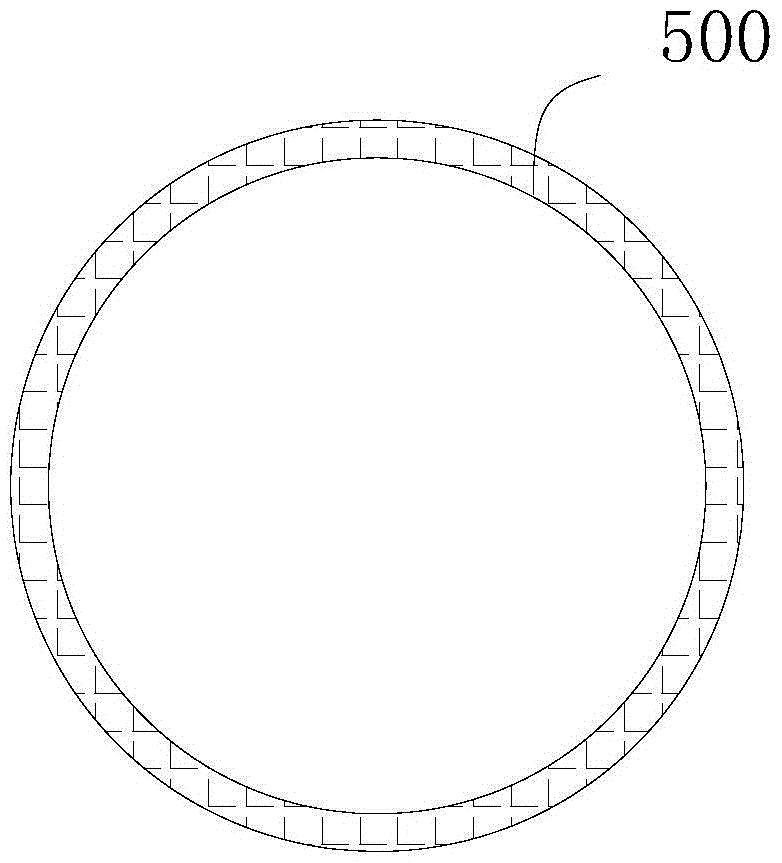

[0070] Production of dark chocolate lollipop shells: Melt 30 parts by weight of dark chocolate to a fluid state and pour it into one hemisphere of a 30mm spherical mould, then combine the other hemisphere with the hemisphere filled with melted chocolate, pass Vibration makes it cover the inner surface of the spherical mold. When the temperature drops below 20°C, the chocolate in the spherical container is cooled and molded, solidifies on the inner surface of the mold, and forms a spherical hollow shell. Open the mold and it can be used.

[0071] Production of yogurt: Mix 63 parts by weight of raw milk with 0.07 parts by weight of whey protein powder, add 4.9 parts by weight of white sugar, 0.07 parts by weight of butter, and heat up to 65°C, homogenize, and the homogenization pressure is 150bar, and then Sterilize by raising the temperature to 95°C for 5 minutes, inoculate Streptococcus thermophilus and Lactobacillus bulgaricus, ferment to pH 4.6, cool to 18°C, and cool at 2°C ...

Embodiment 2

[0075] Production of the white chocolate lollipop shell: Melt 40 parts by weight of white chocolate to a fluid state and pour it into one hemisphere of a 20mm spherical mold, then combine the other hemisphere with the hemisphere filled with melted chocolate, Vibrate to make it cover the inner surface of the spherical mold. When the temperature drops below 20°C, the chocolate in the spherical container is cooled and molded, solidified on the inner surface of the mold to form a spherical hollow shell, and the mold can be opened for use.

[0076] Production of yogurt: Mix 49 parts by weight of raw milk with 2.2 parts by weight of whey protein powder, add 4.2 parts by weight of white sugar, 2.7 parts by weight of butter, and heat up to 65°C, homogenize, and the homogenization pressure is 160bar, then Sterilize by raising the temperature to 95°C for 5 minutes, inoculate Streptococcus thermophilus and Lactobacillus bulgaricus, ferment to pH 4.6, cool to 19°C, and cool at 4°C for afte...

Embodiment 3

[0080] Production of colored chocolate lollipop shells: Melt 50 parts by weight of colored chocolate to a fluid state, pour it into one hemisphere of a 10mm spherical mold, then combine the other hemisphere with the hemisphere filled with melted chocolate, Vibrate to make it cover the inner surface of the spherical mold. When the temperature drops below 20°C, the chocolate in the spherical container is cooled and molded, solidified on the inner surface of the mold to form a spherical hollow shell, and the mold can be opened for use.

[0081] Production of yogurt: Mix 38 parts by weight of raw milk with 3.6 parts by weight of whey protein powder, add 4.5 parts by weight of white sugar, 4.6 parts by weight of butter and heat up to 65 ° C, homogenize, homogeneous pressure at 170bar, and then heat up Sterilize at 95°C for 5 minutes, inoculate Streptococcus thermophilus and Lactobacillus bulgaricus, ferment to pH 4.6, cool to 20°C, and ripen after cooling at 6°C.

[0082] Filling: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com