Reverse osmosis membrane filter element assembly and water purifier with reverse osmosis membrane filter element assembly

A technology of reverse osmosis membrane and water purifier, applied in the direction of osmosis/dialysis water/sewage treatment, reverse osmosis, semi-permeable membrane separation, etc., can solve the problem of excessive TDS of the initial effluent, so as to ensure the health of drinking water and solve the problem of long-term shutdown Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

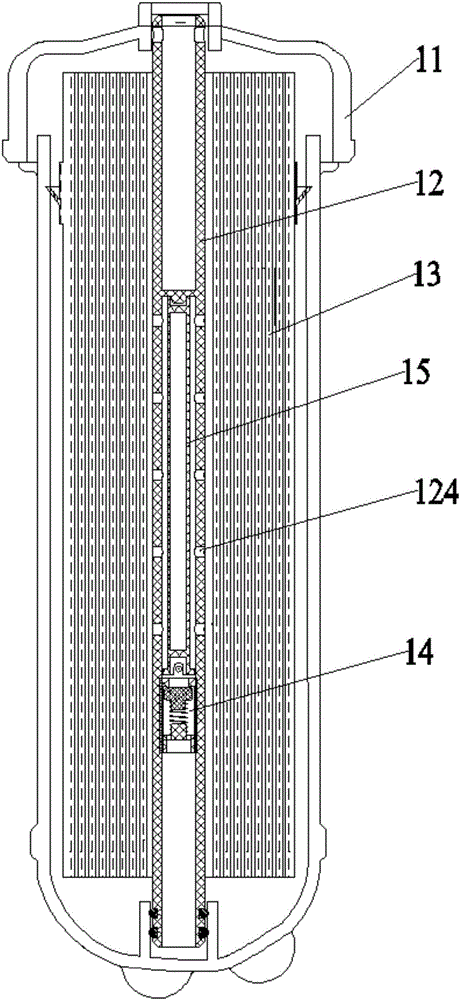

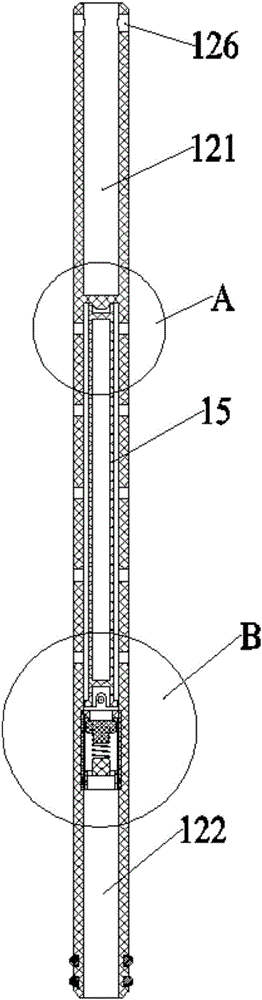

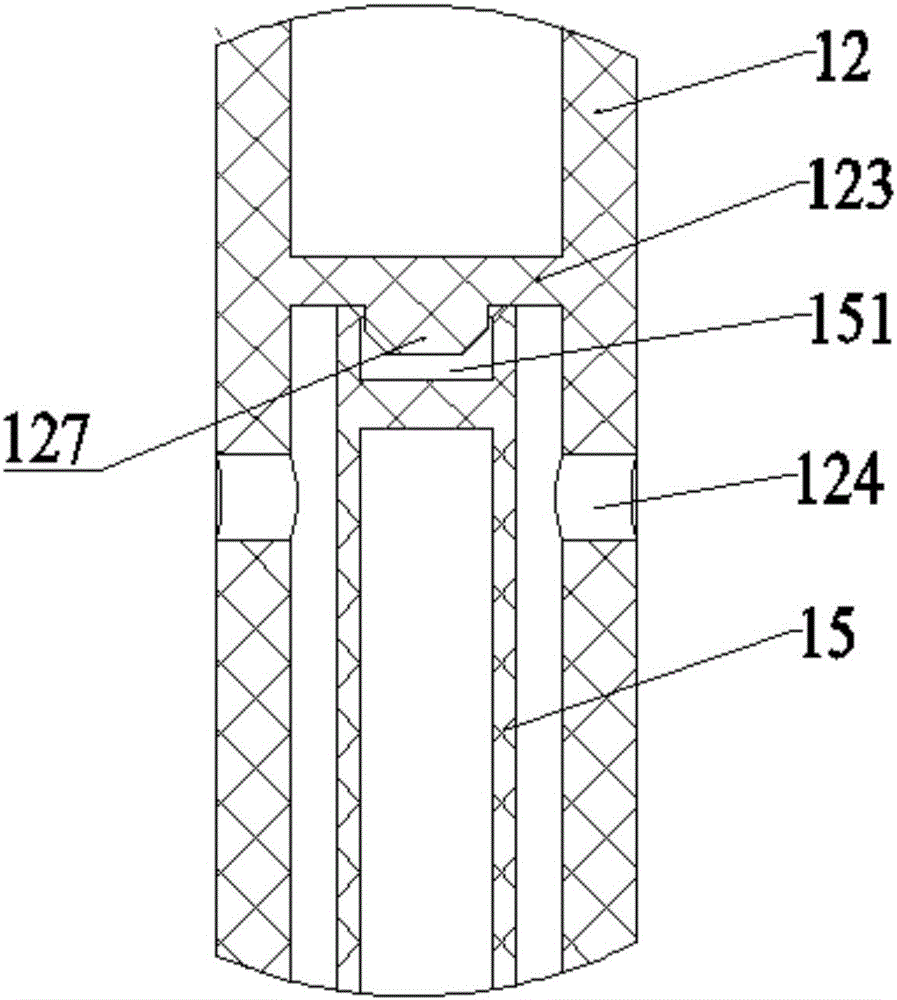

[0031] reverse osmosis membrane filter components, such as Figure 1-Figure 5 As shown, the filter element housing 11 is included, and the filter element housing 11 is provided with a central pipe 12 and a reverse osmosis membrane 13 arranged around the central pipe 12. The central pipe 12 is provided with a central pipe 12 that is divided into an upper pipe 121 and a lower pipe. The water baffle 123 of 122 is provided with a water collecting hole 124 on the wall of the lower pipe 122, and a one-way valve 14 that can cut off the lower pipe 122 and the direction is from top to bottom is provided in the lower pipe 122 and below the water collecting hole 124. The top of the upper tube 121 is a raw water inlet, the side wall of the upper tube 121 is provided with a water outlet 126 communicating with the reverse osmosis membrane 13, and the bottom of the lower tube 122 is a pure water outlet.

[0032] The one-way valve 14 includes a one-way valve housing 141 fixed on the pipe wall...

Embodiment 2

[0049] Same as embodiment 1, the difference is that the bottom of the drain rod 15 is not provided with a limit groove 152, and the wall of the central tube 12 is not provided with a limit pin 125. There are a plurality of protruding points 153 evenly arranged around the drain rod 15 , and there is a gap between the protruding points 153 and the inner wall of the central pipe 12 .

Embodiment 3

[0051] The same as embodiment 1, the difference is that the bottom of the drain rod 15 is provided with a downwardly opening limiting groove 152, and the wall of the central tube 12 is provided with a limiting pin 125 that cooperates with the limiting groove 152. No bumps 153 are provided on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com