Strong stereo spraying chip-discharging system

A powerful and chip-flushing technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of chip accumulation, inability to effectively and timely discharge chips, continuous operation of the machine, etc., to achieve Effects of improving reliability and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

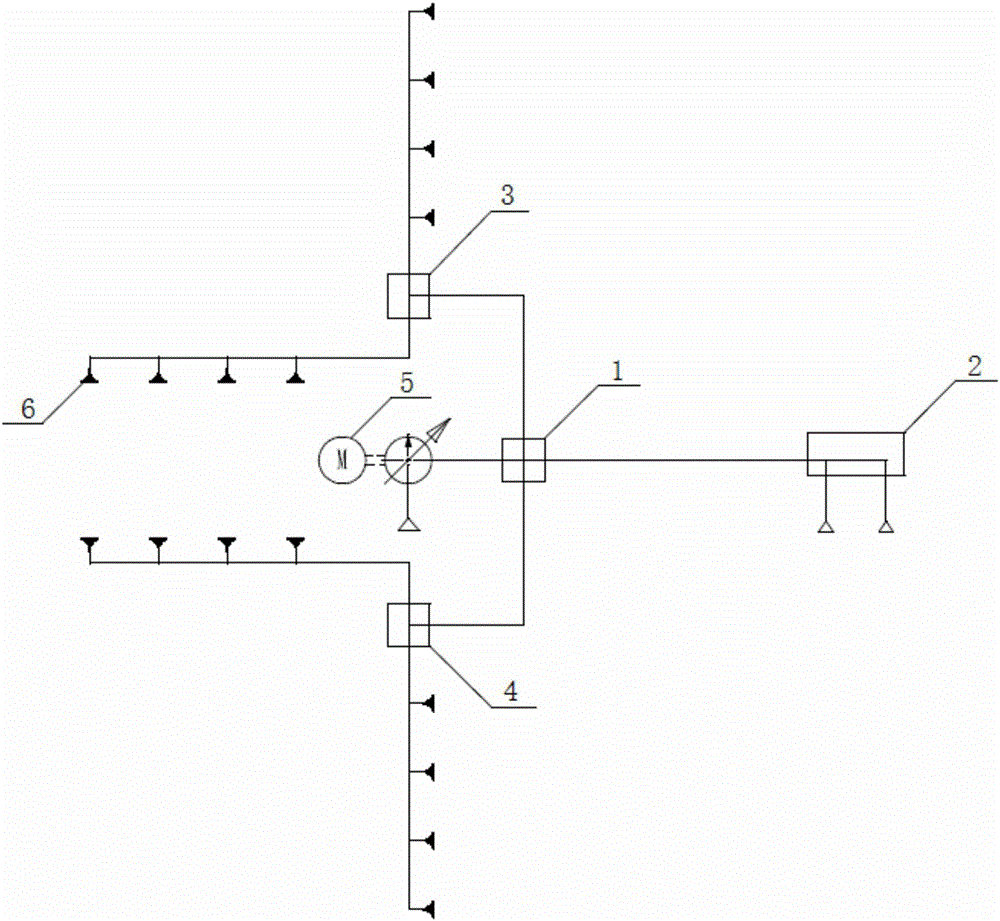

[0017] see figure 1 , a three-dimensional spray powerful chip flushing system, including an oil distribution block A1, an oil distribution block B2, an oil distribution block C3, an oil distribution block D4, a high-pressure water pump 5 and a powerful cooling chip discharge port 6, the outlet of the high-pressure water pump 5 The water port is connected to the oil distribution block A1 through the water pipe, and the oil distribution block A1 is respectively connected to the oil distribution block B2, the oil distribution block C3, and the oil distribution block D4 through the water pipe, and the oil distribution block C3 and the oil distribution block D4 are respectively installed with 8 water pipes. A powerful cooling chip outlet 6.

[0018] Further, the oil separation block C3 of the present invention is connected with two water pipes equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com