A fully enclosed double negative pressure circulation ink supply system for a digital inkjet printing machine

A technology of digital inkjet and printing machine, applied in printing and other directions, it can solve the problems of ink leakage, unstable ink pressure and insufficient ink supply in the print head, and achieve the effect of smooth inkjet, sufficient ink volume and stable ink pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

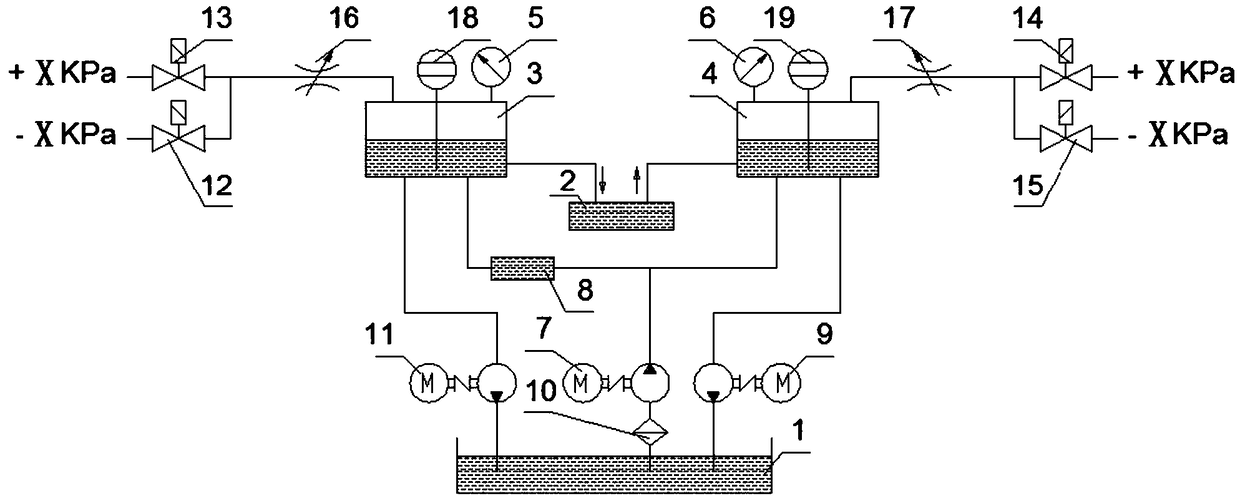

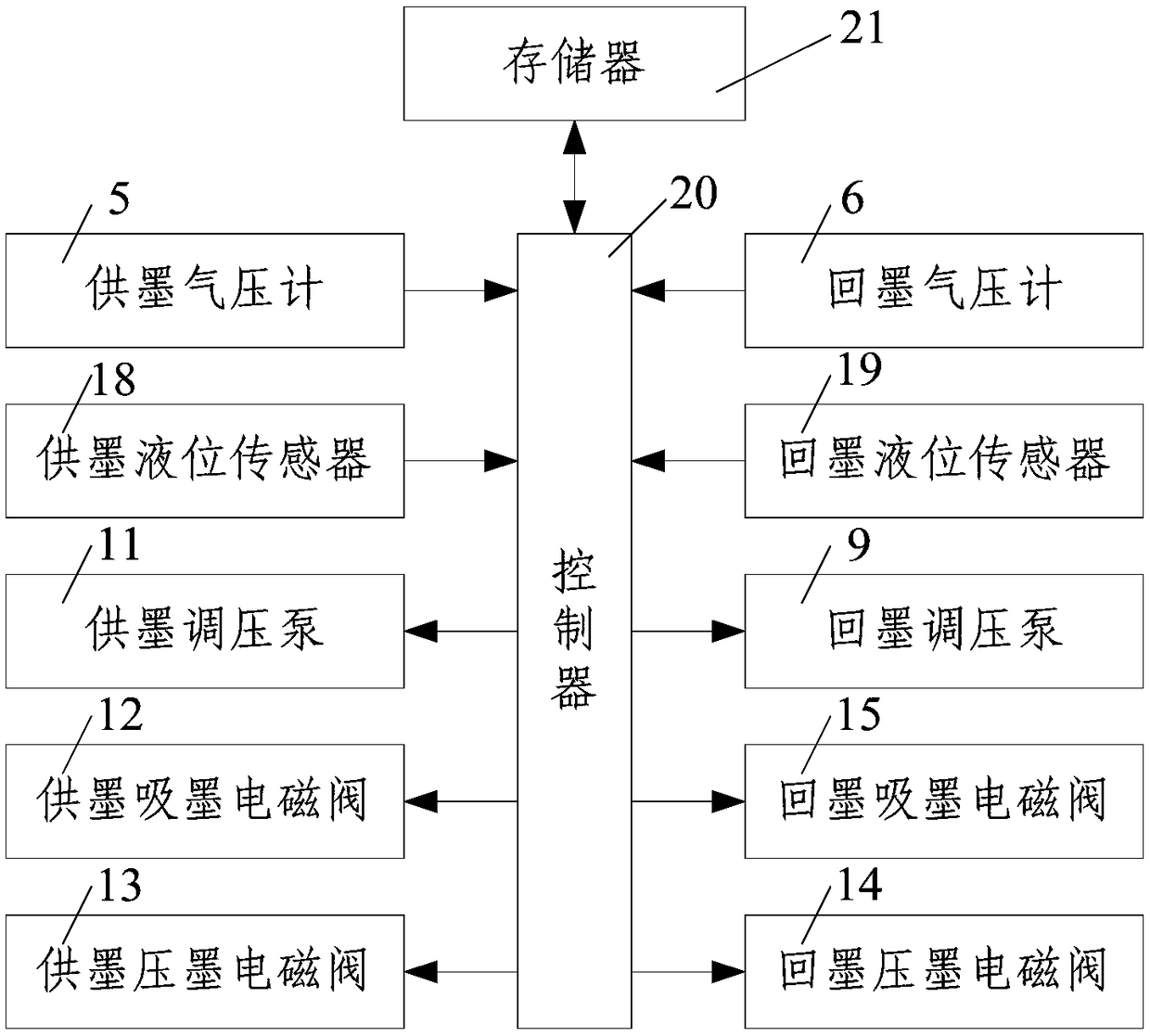

[0030] Such as figure 1 with figure 2 As shown, the present invention includes an ink tank 1, a negative pressure ink supply device for delivering ink to the print head 2, a negative pressure ink return device for recovering the remaining ink of the print head 2, and a negative pressure ink supply device for centralized control of the negative pressure ink supply device. The controller 20 of the ink device and the negative pressure ink return device for circulating ink supply is connected to the controller 20 for storing the vacuum degree threshold value of the negative pressure ink supply device and the vacuum degree threshold value of the negative pressure ink return device memory 21, the negative pressure ink supply device includes an ink supply box 3, an ink supply air pressure adjustment unit for adjusting the air pressure in the ink supply box 3, and an ink supply level adjustment unit for adjusting the liquid level in the ink supply box 3, the said The negative pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com