Drug powder trace filling machine

A filling machine and powder technology, which is applied in the field of pharmaceutical powder micro-filling machines, can solve problems such as incomplete design parameters, inability to truly and well realize powder, and inability to further in-depth research, etc., to achieve positioning Quantitative free filling, high vibration transmission efficiency and low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

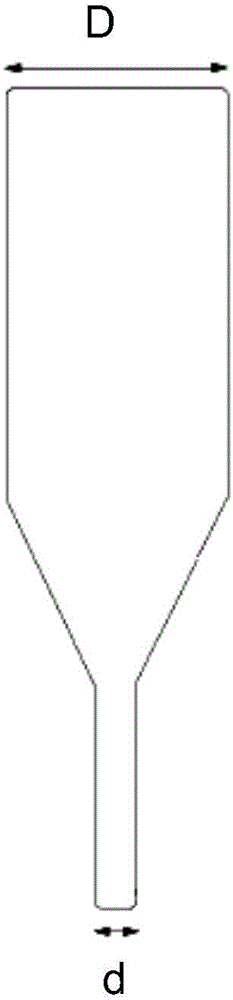

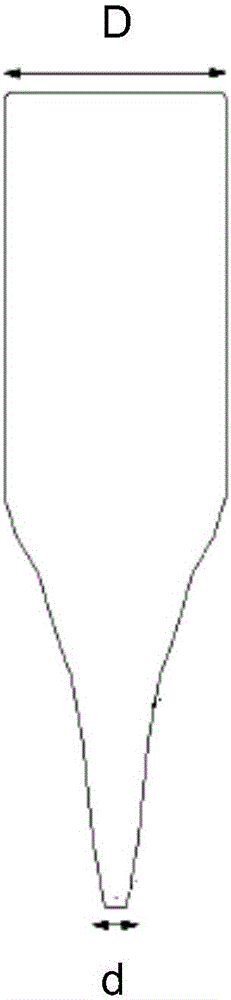

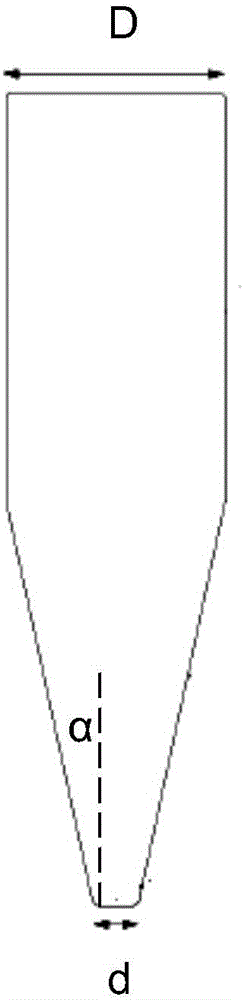

[0033] The pharmaceutical powder micro-filling machine of the present invention is as figure 2 As shown, it mainly includes a fuselage 100 , a precision displacement platform 101 disposed in the fuselage 100 , a filling platform 102 , and a filling nozzle 103 . Wherein, the filling nozzle 103 is arranged on the filling platform 102, and can move relative positions through the precision displacement platform 101 (the filling platform 102 can be fixed, the filling nozzle 103 can be moved, or the filling nozzle 103 can be fixed, and the filling Two ways of moving the filling platform 102) are used to fill the filling objects such as capsules and vesicles on the filling platform 102 below it to fill the drug powder. The filling nozzle 103 may include a nozzle housing 10, a filling flow channel 11 arranged in the nozzle housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com