A kind of pulp foam material and preparation method thereof

A foam material and pulp technology, applied in the field of biomass foam materials, can solve the problems of high cost and application limitations of cellulose foam materials, and achieve the effects of low cost, simple operation, and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

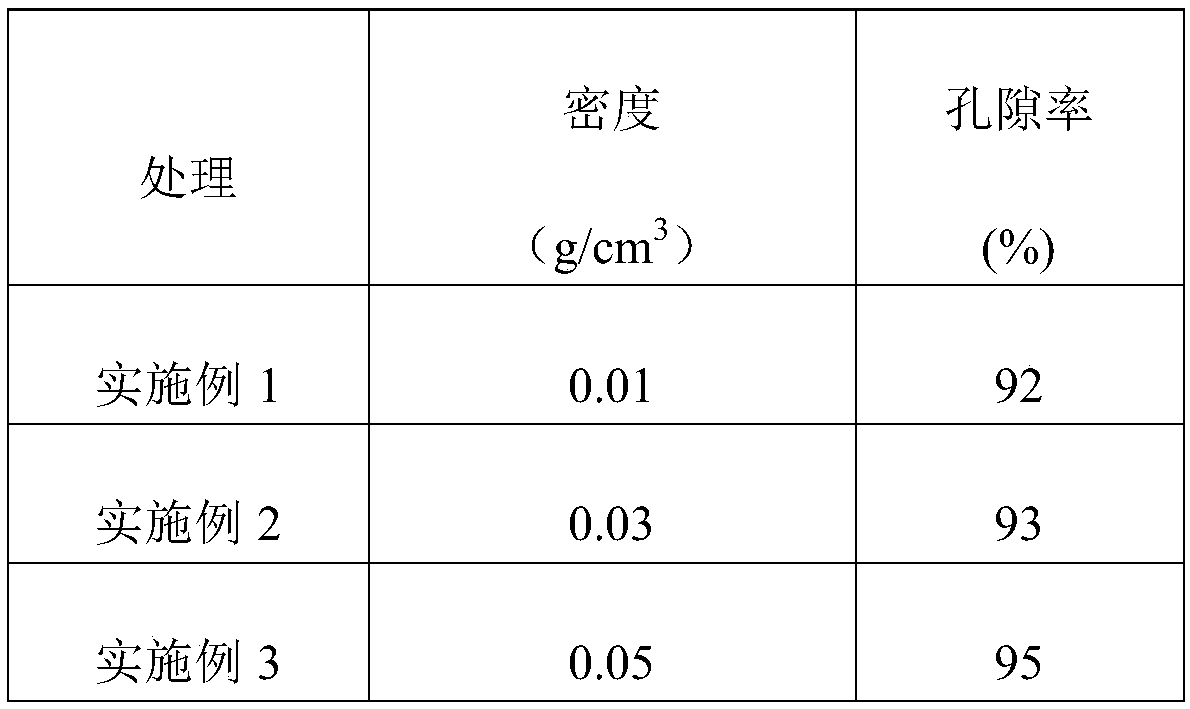

Embodiment 1

[0022] A pulp foam material, comprising the following components by weight: 0.5 parts of pulp, 0.005 parts of surfactant, 0.0005 parts of cationic polyacrylamide and 97.4 parts of water; the pulp is bleached wood pulp; the surface active The agent is Tween 80.

[0023] The preparation method of described pulp foam material is characterized in that, comprises the following steps:

[0024] (1) Take the pulp and water by weight, stir it mechanically to disperse it evenly, and obtain the pulp solution; the rotating speed of the mechanical stirring is 500r / min, and the stirring time is 0.5h;

[0025] (2) take surfactant again and add in the pulp solution that step (1) obtains, foam by mechanical stirring, obtain pulp foaming solution; The stirring speed of mechanical stirring foaming is 1000r / min, and foaming time is 0.5 h;

[0026] (3) Add cationic polyacrylamide to the pulp foaming solution obtained in step (2); continue stirring for 0.5 h, at a stirring speed of 1000 r / min, st...

Embodiment 2

[0028] A pulp foam material, comprising the following components by weight: 2.5 parts of pulp, 0.125 parts of surfactant, 0.0125 parts of cationic polyacrylamide and 99.5 parts of water; said pulp is bleached bamboo pulp; said surface active The agent is sodium lauryl sulfate.

[0029] The preparation method of described pulp foam material is characterized in that, comprises the following steps:

[0030] (1) Take the pulp and water by weight, stir it mechanically to disperse it evenly, and obtain the pulp solution; the rotating speed of the mechanical stirring is 5000r / min, and the stirring time is 2.0h;

[0031] (2) take surfactant again and add in the pulp solution that step (1) obtains, foam by mechanical stirring, obtain pulp foaming solution; The stirring speed of mechanical stirring foaming is 5000r / min, and foaming time is 5.0 h;

[0032] (3) Get cationic polyacrylamide and add in the paper pulp foaming solution that step (2) obtains; Continue to stir for 2h, the spee...

Embodiment 3

[0034] A pulp foam material, comprising the following components by weight: 1.0 parts of pulp, 0.05 parts of surfactant, 0.005 parts of cationic polyacrylamide and 98 parts of water; the pulp is bleached cane pulp; the surface active The agent is Tween 80.

[0035] The preparation method of described pulp foam material is characterized in that, comprises the following steps:

[0036] (1) Take paper pulp and water by weight ratio, make it uniform dispersion by mechanical stirring, obtain paper pulp solution; The rotating speed of mechanical stirring is 3000r / min, stirring time 1.0h;

[0037] (2) take surfactant again and add in the pulp solution that step (1) obtains, foam by mechanical stirring, obtain pulp foaming solution; The stirring speed of mechanical stirring foaming is 3000r / min, and foaming time is 2.0 h;

[0038] (3) Add cationic polyacrylamide to the pulp foaming solution obtained in step (2); continue to stir for 1.0 h, at a stirring speed of 2000 r / min, stop sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com