Method for producing feed oil and corn germ meal feed using dehydrated oil bottoms

A technology of corn germ meal and dehydrated oil, applied in animal feed, animal feed, applications, etc., can solve the problems of dehydrated oil feet being gelatinous, difficult to transfer, difficult to use in feed factories, etc., to achieve the goal of increasing phosphorus content and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

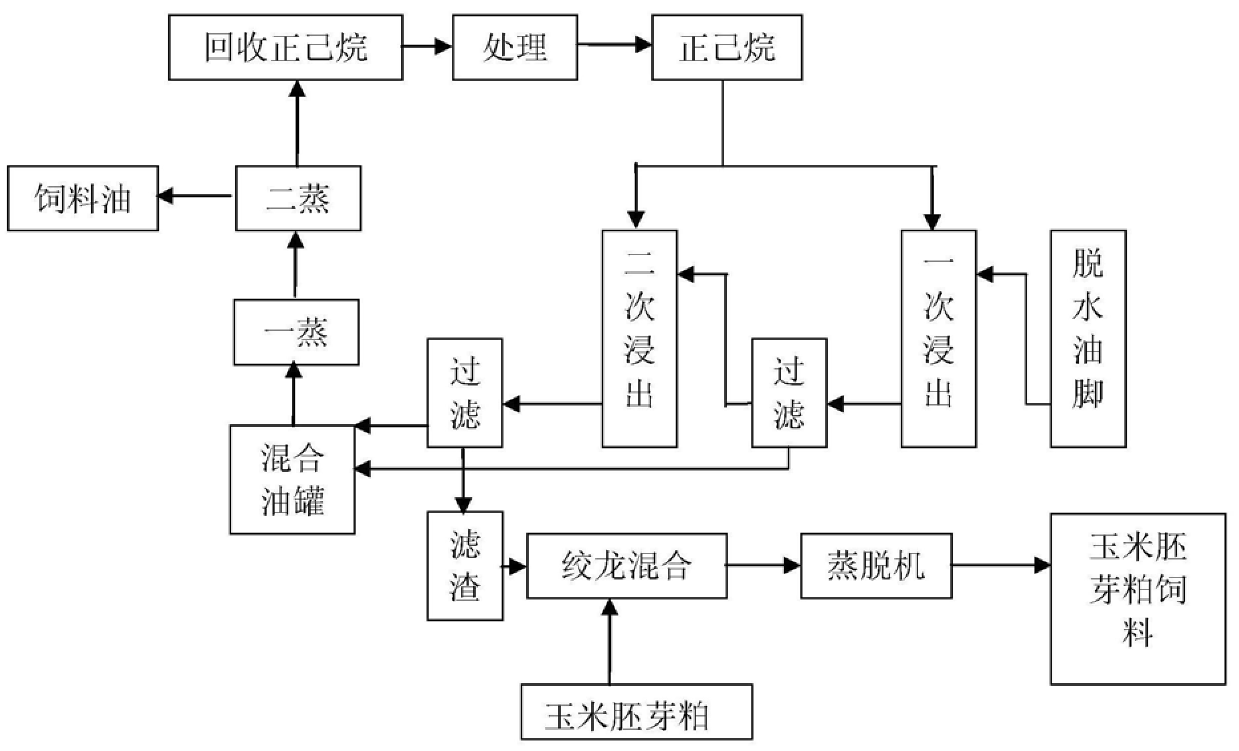

Method used

Image

Examples

Embodiment 1

[0036] A method for producing feed oil and corn germ meal feed by adopting dehydrated oil bottoms, the steps are as follows:

[0037] (1) In the experiment, the corn oil production line adopts the soap-free refining production process, the degumming temperature is 80°C, the phosphoric acid concentration is 75%, the phosphoric acid addition amount is 0.80‰ of the oil weight, the degumming time is 30min, and the phosphoric acid is neutralized by adding light alkaline water (the addition amount of alkali is calculated according to the addition amount of phosphoric acid), and the water of the same temperature is added and washed, and the amount of water is calculated by 3.5% of oil weight, and the oil foot is separated.

[0038] (2) Steam the de-oiled feet to obtain dehydrated oily feet.

[0039] (3) Take 518.7kg of dehydrated oil feet and 3.31% moisture. In one leaching, the volume ratio of dehydrated oil bottoms to n-hexane is 1:6, the leaching time is 20min, and the leaching t...

Embodiment 2

[0046] A method for producing feed oil and corn germ meal feed by adopting dehydrated oil bottoms, the steps are as follows:

[0047] (1) In the experiment, the corn oil production line adopts a soap-free refining production process. The degumming temperature is 75°C, the phosphoric acid concentration is 70%, the phosphoric acid addition amount is 0.75‰ of the oil weight, the degumming time is 25min, and the phosphoric acid is neutralized by adding light alkaline water (the addition amount of alkali is calculated according to the addition amount of phosphoric acid), and the water of the same temperature is added and washed, and the amount of water is calculated by 3.5% of oil weight, and the oil foot is separated.

[0048] (2) Steam the de-oiled feet to obtain dehydrated oily feet.

[0049] (3) Get 543.2kg of dehydrated oil feet, moisture 3.15%. In one leaching, the volume ratio of dehydrated oil bottoms to n-hexane is 1:7, the leaching time is 15 minutes, and the leaching te...

Embodiment 3

[0056] A method for producing feed oil and corn germ meal feed by adopting dehydrated oil bottoms, the steps are as follows:

[0057] (1) In the experiment, the corn oil production line adopts the soap-free refining production process, the degumming temperature is 85°C, the phosphoric acid concentration is 80%, the phosphoric acid addition amount is 0.85‰ of the oil weight, the degumming time is 35min, and the phosphoric acid is neutralized by adding light alkaline water (the addition amount of alkali is calculated according to the addition amount of phosphoric acid), and the water of the same temperature is added for washing, and the amount of water is calculated by 4.0% of the oil weight, and the oil foot is separated.

[0058] (2) Steam the de-oiled feet to obtain dehydrated oily feet.

[0059] (3) Take 501.3 kg of dehydrated oil feet and 4.21% moisture. In one leaching, the volume ratio of dehydrated oil bottoms to n-hexane is 1:8, the leaching time is 25min, and the leac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com