A kind of sulfate-reducing bacteria activator and its application in microbial oil recovery

A microbial oil recovery and sulfate technology, applied in the field of oil recovery, can solve problems such as the hazards of the reinjection water system and corrosion of oilfield pipelines, and achieve the effects of rapid directional activation, rapid activation, and enhanced biochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

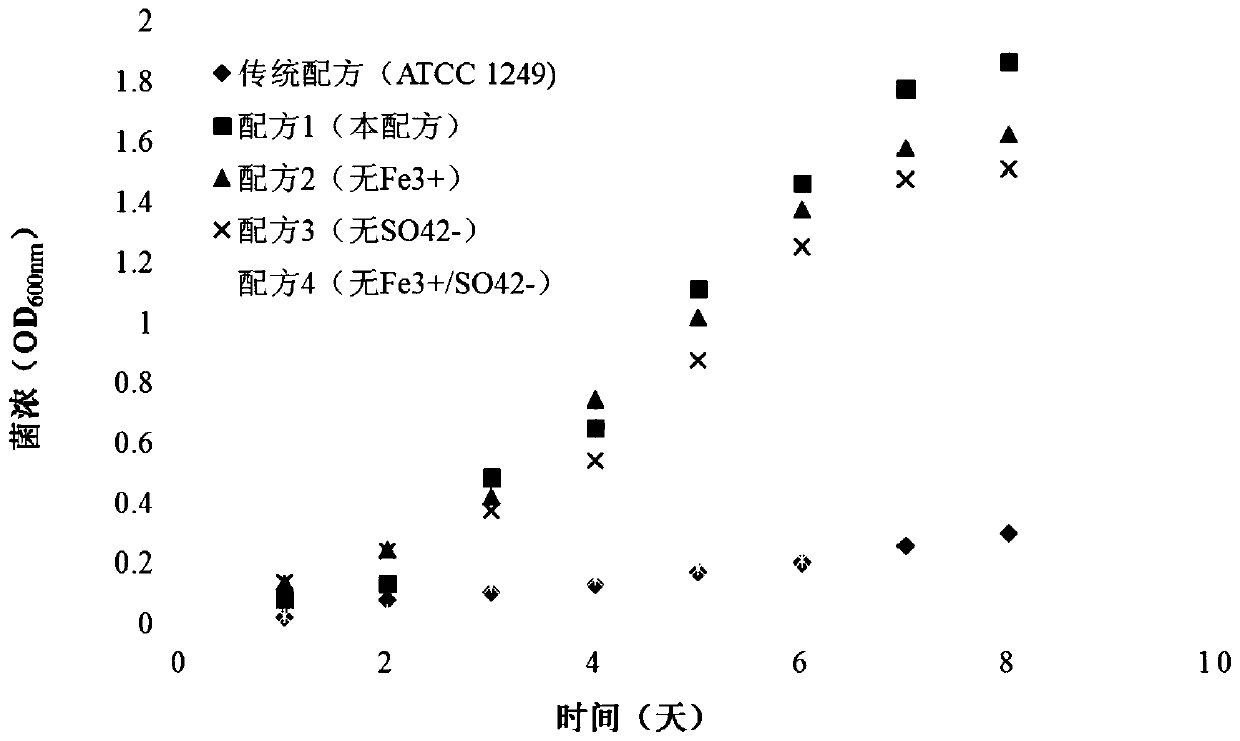

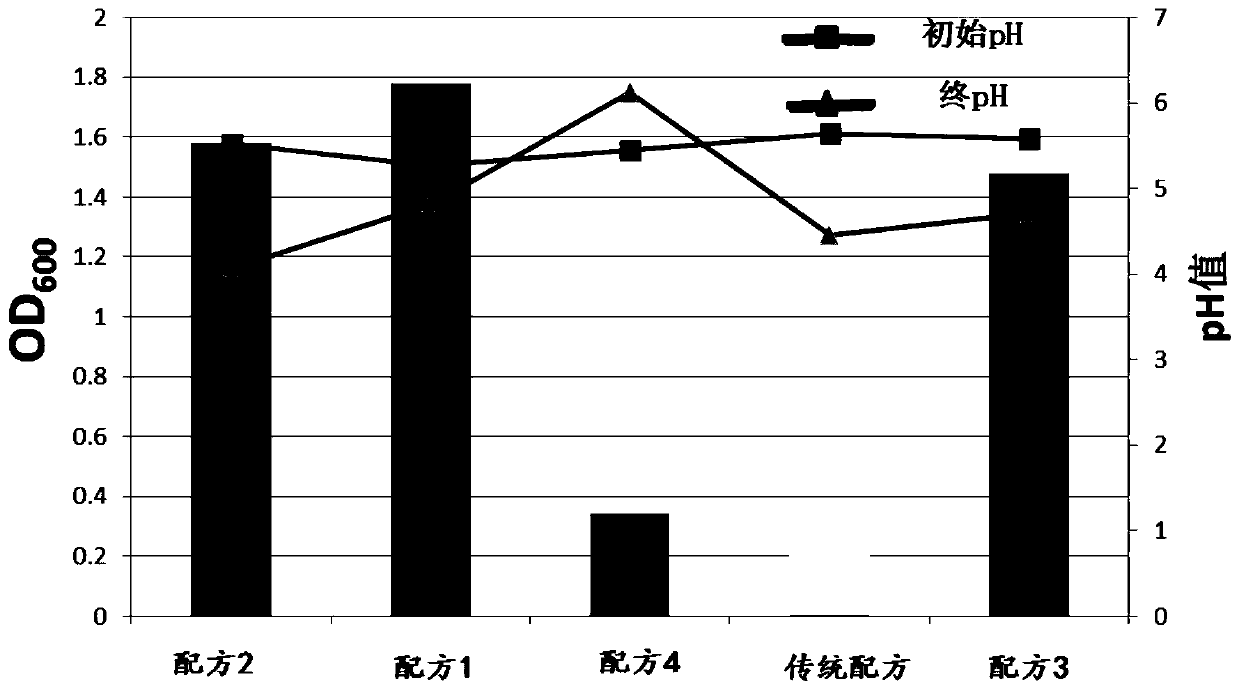

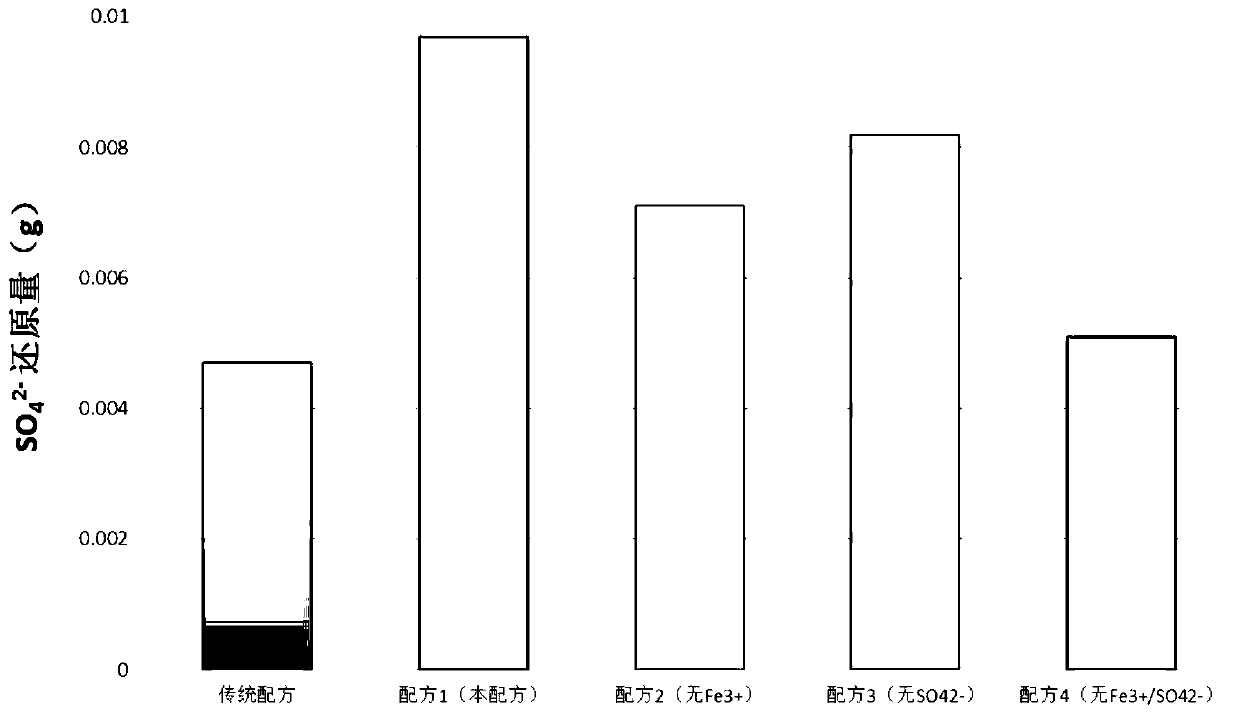

[0043] This implementation provides a kind of sulfate-reducing bacteria activator (formula 1), wherein, in mass / volume ratio, every liter of sulfate-reducing bacteria activator comprises the following components:

[0044] 0.6% molasses, 0.4% yeast powder, 0.2% peptone, 0.2% Tween 80, 0.5% K 2 HPO 4 , 0.2% NaCl, 0.2% MgSO 4 , 0.10% FeCl 3 and the remainder of the water.

Embodiment 2

[0060] This implementation provides a kind of sulfate-reducing bacteria freeze-dried powder, and the specific preparation steps are as follows:

[0061] a. formula 1 that sulfate-reducing bacteria bacterial strain adopts embodiment 1 to carry out enrichment culture, in 13 days, cultivate to optimal state (by OD 600nm The detection is between 1.2-1.8); then the cells are extracted and made into a suspension with water;

[0062] b. Put the above suspension into a -86°C refrigerator, and freeze it at ultra-low temperature for more than 48 hours;

[0063] c. Put the frozen cells into a Labconco lyophilizer, and dry them at low temperature for 18-24 hours to obtain lyophilized powder of sulfate-reducing bacteria.

Embodiment 3

[0068] The present embodiment provides the indoor oil displacement experiment of sulfate reducing bacteria, specifically as follows:

[0069] (1) Oil displacement ability of sulfate reducing bacteria

[0070] In order to confirm the oil displacement ability of sulfate reducing bacteria, the oil displacement experiment of injecting fresh bacteria was carried out first, and the specific steps are as follows:

[0071] a. Cultivate the sulfate-reducing bacteria strains with ATCC 1249 medium for about 28 days, then add sterilized deionized water and fully mix them into a bacterial suspension;

[0072] b Inject the bacterial suspension into the rock core after water flooding, and statically revive for 48 hours;

[0073] c. Carry out post-water flooding experiments.

[0074] After testing, injecting 0.5PV (void volume of 0.5 cores) with the enriched cultured sulfate-reducing bacteria solution can increase the recovery rate by 11.78% on the basis of water flooding. Very obvious (te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com