Heat treatment process for improving strength and low-temperature impact toughness of anti-corrosion steel casting

A technology of low temperature impact toughness and steel castings, which is applied in the field of production of corrosion-resistant steel castings for bridge supports, can solve the problems of yield strength not reaching 400MPa level, tensile strength not reaching 550MPa level, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

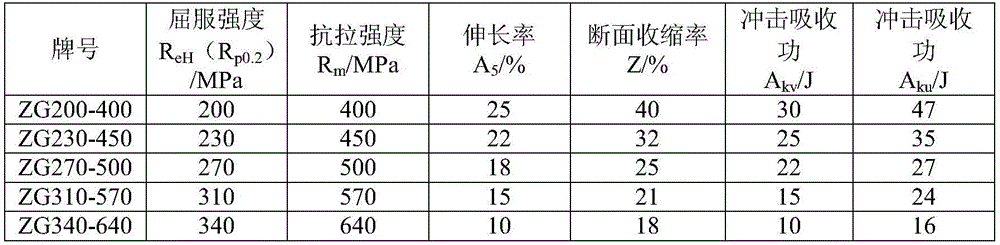

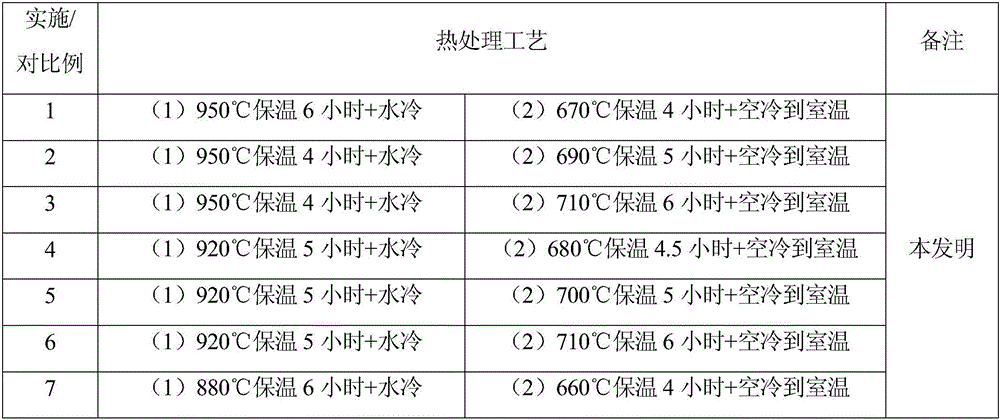

[0027] See Tables 2, 3, and 4 for the main chemical components, heat treatment process, and mechanical properties of the embodiments of the present invention and comparative examples.

[0028] Each embodiment of table 2 and comparative example main chemical composition (%)

[0029] test steel C Si mn P S Cu Cr Ni Al V Mo Example 1 0.10 0.50 1.38 0.005 0.006 0.39 3.14 1.44 0.12 - 0.04 Example 2 0.15 0.21 0.87 0.007 0.004 0.35 4.65 0.39 0.23 - - Example 3 0.08 0.65 0.79 0.008 0.005 0.57 4.90 0.58 0.06 0.04 - Example 4 0.12 0.46 0.98 0.006 0.005 0.62 3.54 0.73 0.18 - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com