Barrel of rotary water-spraying cooling device

A water spray cooling and cylinder technology, applied in the field of cylinder coolers, can solve the problems affecting the reduction rate and pulverization rate of reduced iron pellets, the difficulty of installation and maintenance, and the easy flow of spray cooling water, etc. Small floor area, improved cooling effect, simple installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

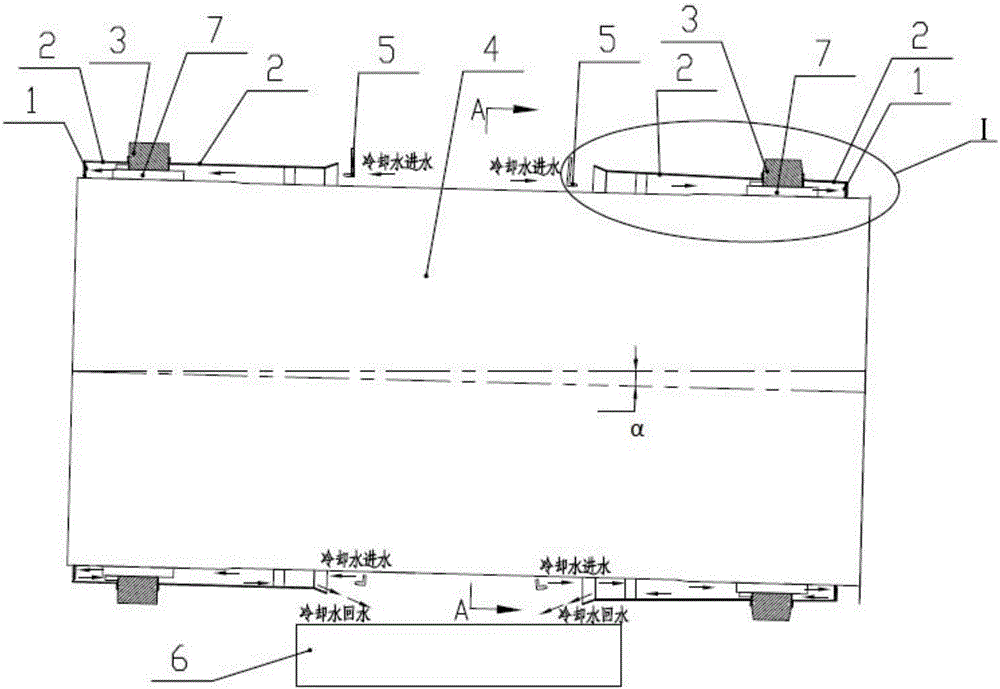

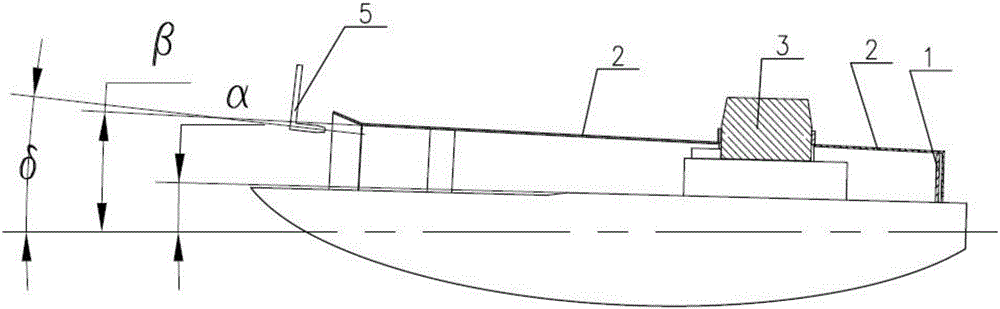

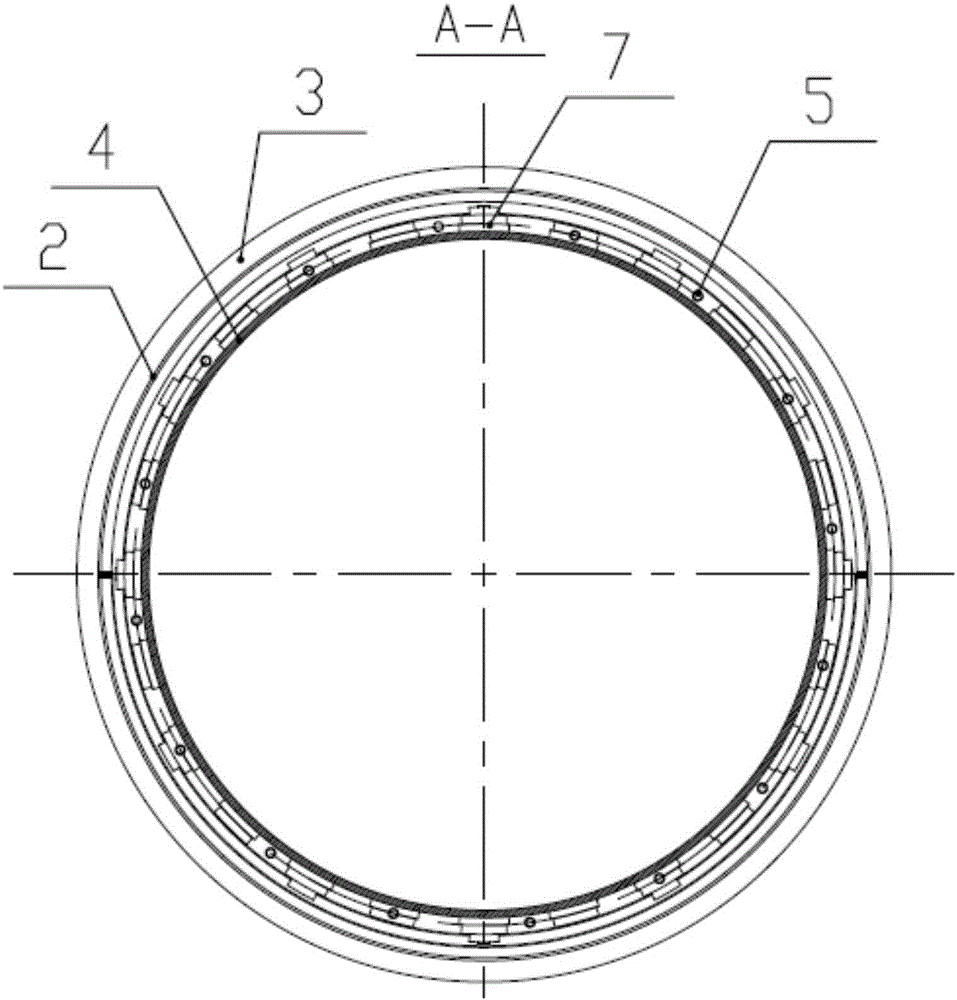

[0024] Such as figure 1 and image 3 As shown, a cylinder of a rotary water spray cooling device includes a water retaining plate 1, a water retaining cover 2, a wheel belt 3, a cylinder body 4, a cooling water nozzle 5, a water cooling box 6, a wheel belt backing plate 7, and a wheel belt 3 are supported by a number of tire backing plates 7 and arranged at both ends of the outer circle of the cylinder 4. The water shield 2 is installed on both sides of the tire 3, and the two sides of the tire 3 at both ends are respectively equipped with water shields 2 , the cooling water nozzle 5 is installed on the water inlet side of the water shield 2, the water inlet side of the water shield 2 is the side facing the middle of the cylinder body, the other side is the water blocking side, and the other side of the water shield 2 A water baffle 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com