A method for removing arsenic from arsenic-containing dust and comprehensively recycling valuable elements

A technology for valuable elements and arsenic soot, applied in the field of metallurgy, can solve the problems of low comprehensive recovery rate of valuable elements, limited market for arsenic products, untreated sodium arsenate, etc. Wide range of effects with low arsenic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

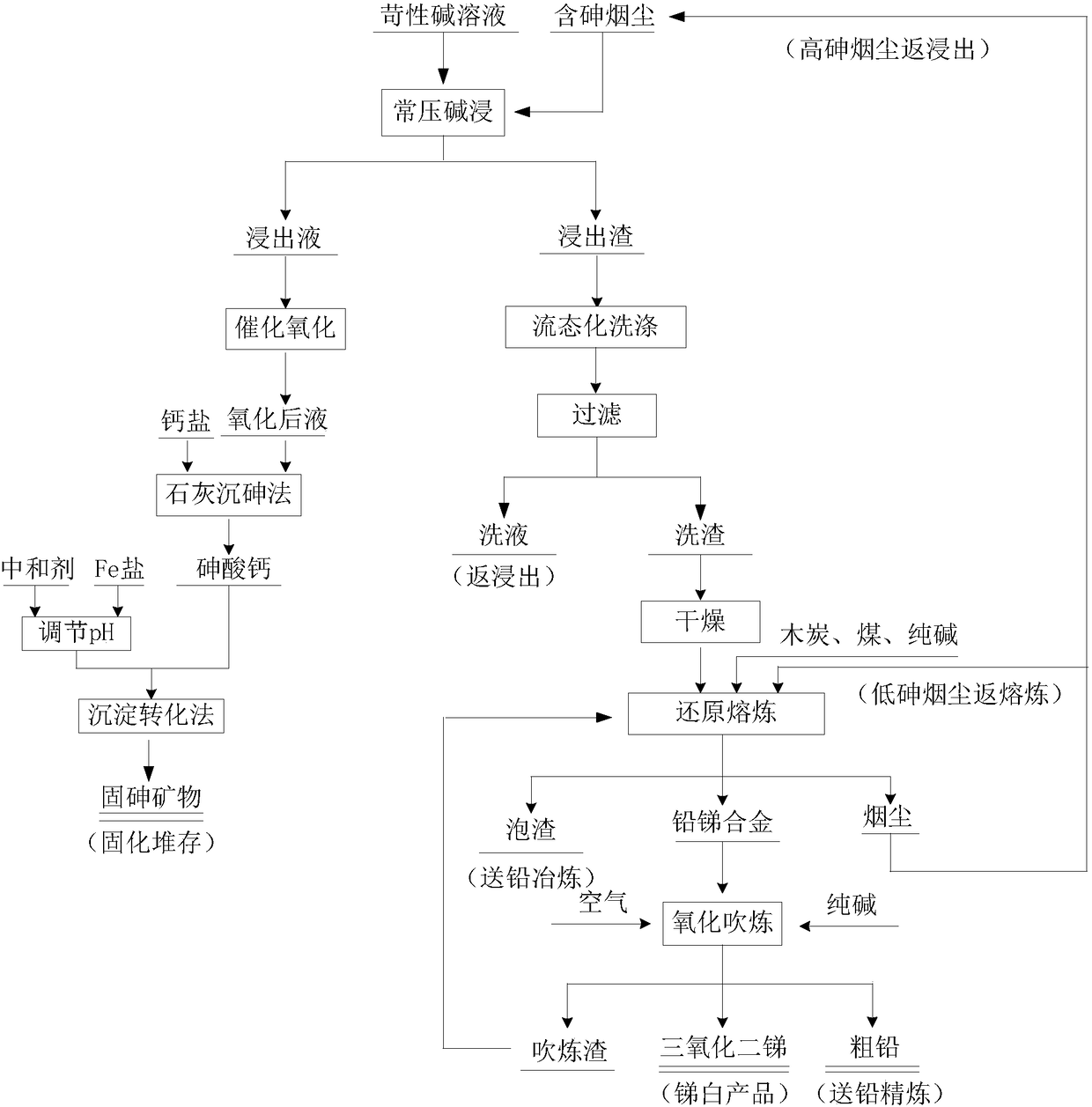

Method used

Image

Examples

Embodiment 1

[0054] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, it includes the following main components in terms of mass percentage: Pb 5.26%, As 39.65%, Sn 0.5%, Sb 29.36%, Zn 0.12%, Se 0.04%.

[0055] Weigh a certain mass of the high arsenic and antimony fumes in the reaction kettle, according to the liquid-solid volume mass ratio of 10:1 (ml:g), the stirring speed is 700r / min, the NaOH concentration is 1mol / L, the leaching temperature is 80°C, and the leaching time is 2h. conditions for leaching experiments. After leaching, the slurry was removed and separated by filtration; the arsenic leaching rate was measured to be 72.36%, and the concentrations of elements in the leach solution were Pb 86.00ppm, Se 1.80ppm, Zn 20ppm, Sb 1.36g / L, and As 28.69g / L.

[0056] The leaching solution adopts the method of catalytic oxidation to decompose As 3+ Oxidized to As 5+ , the control conditions are as follows: the oxygen flow rate is 5L / min, the As / Mn molar ra...

Embodiment 2

[0061] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, it includes the following main components in terms of mass percentage: Pb 10.39%, As 34.59%, Sn 1.45%, Sb 20.54%, Zn 0.11%, Se 0.24%.

[0062] Weigh a certain mass of the high arsenic and antimony fumes in the reaction kettle, according to the liquid-solid volume mass ratio of 10:1 (ml:g), the stirring speed is 700r / min, the NaOH concentration is 3mol / L, the leaching temperature is 50°C, and the leaching time is 4h. conditions for leaching experiments. After leaching, the slurry was removed and separated by filtration; the arsenic leaching rate was measured to be 52.06%, and the concentration of elements in the leaching solution were Pb 87ppm, Se 0.52ppm, Zn 71ppm, Sb 1.24g / L, and As 18.01g / L.

[0063] The leaching solution adopts the method of catalytic oxidation to decompose As 3+ Oxidized to As 5+ , the control conditions are as follows: the oxygen flow rate is 10L / min, the As / Mn molar ...

Embodiment 3

[0068] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, it includes the following main components in terms of mass percentage: Pb 19.57%, As 24.26%, Sn 1.47%, Sb 30.45%, Zn 0.16%, Se 0.21%.

[0069] Weigh a certain mass of the high arsenic and antimony fumes in the reaction kettle, according to the liquid-solid volume mass ratio 5:1 (ml:g), stirring speed 1000r / min, NaOH concentration 1mol / L, leaching temperature 30 ℃, leaching time 2h conditions for leaching experiments. After leaching, the slurry was removed and separated by filtration; the arsenic leaching rate was measured to be 42.26%, and the concentrations of elements in the leach solution were Pb 124ppm, Se 0.67ppm, Zn 107ppm, Sb 2.02g / L, and As 10.25g / L.

[0070] The leaching solution adopts the method of catalytic oxidation to decompose As 3+ Oxidized to As 5+ , the control conditions are as follows: the oxygen flow rate is 1L / min, the As / Mn molar ratio is controlled at 20:1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com