Novel substitutive alkali and preparation method thereof

A new technology of substitute alkali, which is applied in the field of new substitute alkali and its preparation, can solve the problems of unstable dyeing rate and deviation of color light, etc., and achieve the effects of reducing transportation costs, saving storage space, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

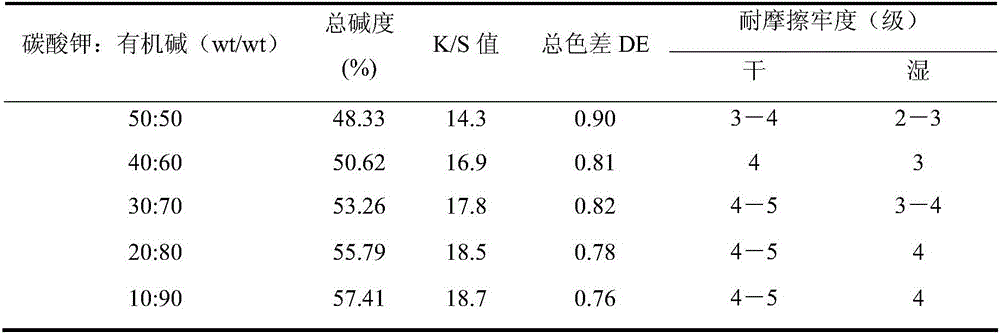

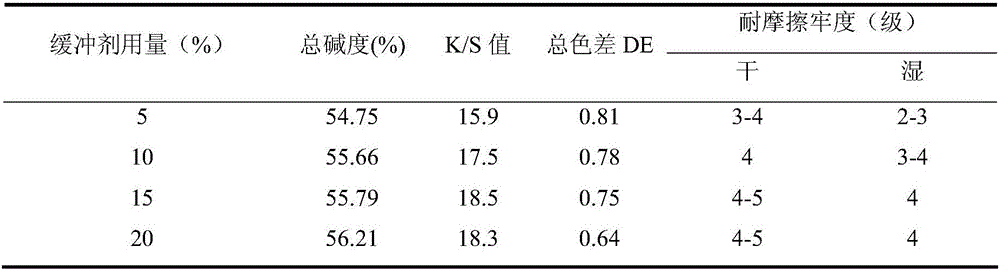

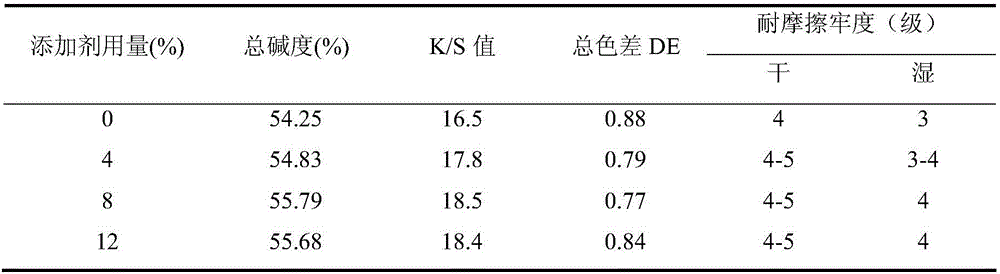

Method used

Image

Examples

Embodiment 1

[0018] A new substitute base is made from the following raw materials in weight percentage: 82% of organic base and potassium carbonate, 10% of buffering agent and 8% of additives. The weight ratio of the organic base and potassium carbonate is 10:90. The organic base is triethanolamine, the buffering agent is sodium metasilicate, and the additive is sodium hydroxide.

[0019] The preparation method of the novel substitute base comprises mixing an organic base with potassium carbonate, a buffer and an additive in proportion, and stirring at room temperature until it becomes a colorless transparent liquid.

Embodiment 2

[0021] A novel substitute base and preparation method thereof, the same as in Example 1, the difference is that the novel base substitute is made of the following raw materials in percentage by weight: organic base and potassium carbonate 73%, buffering agent 15%, additive 12% . Wherein, the weight ratio of organic base and potassium carbonate is 20:80.

Embodiment 3

[0023] A novel substitute base and preparation method thereof, the same as in Example 1, the difference is that the novel substitute base is made of the following raw materials in weight percentage: organic base and potassium carbonate 77%, buffer 15%, additive 8% . Wherein, the weight ratio of organic base and potassium carbonate is 20:80.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com