Prefabricated reinforced concrete composite heat-preservation outer wall plate and manufacturing and installation method thereof

A reinforced concrete and composite thermal insulation technology, applied in thermal insulation, building components and other directions, can solve the problems of thermal insulation thickness restriction, thermal insulation board falling off, unfavorable hoisting, etc., to achieve the effect of reducing weight, safe installation and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0045] The invention discloses a method for manufacturing a prefabricated reinforced concrete composite thermal insulation exterior wall panel, which comprises:

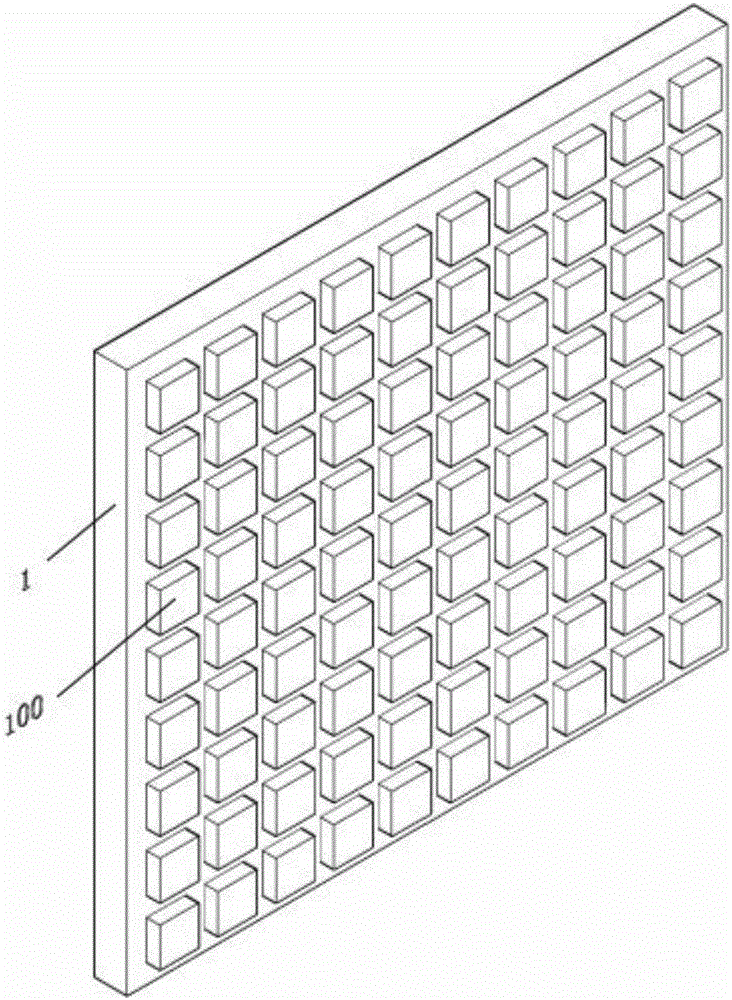

[0046] Step 1, making an insulating board with mounting bumps in a mold with grooves;

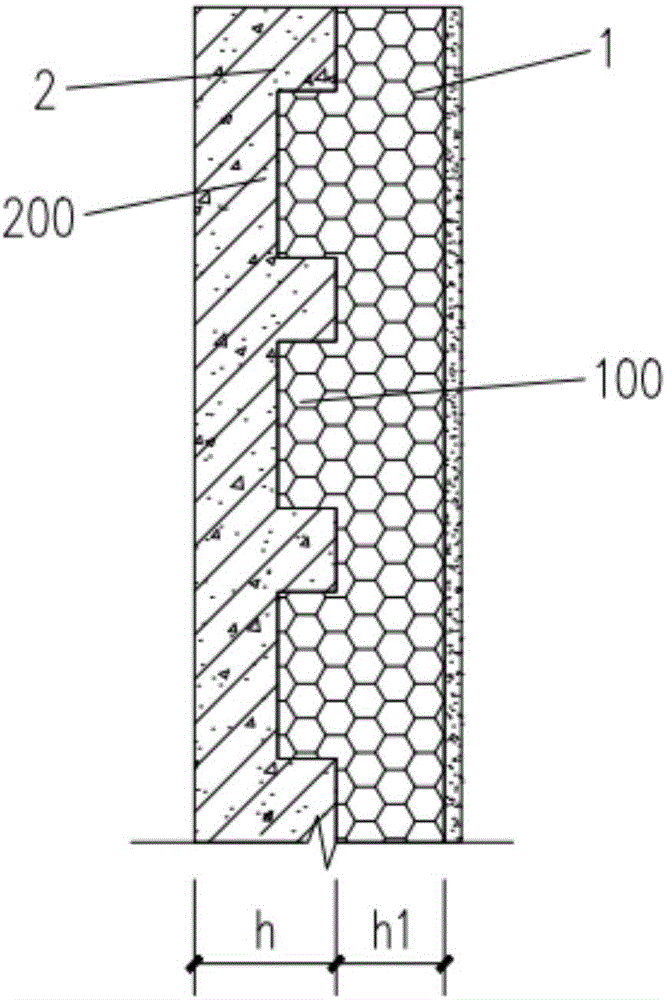

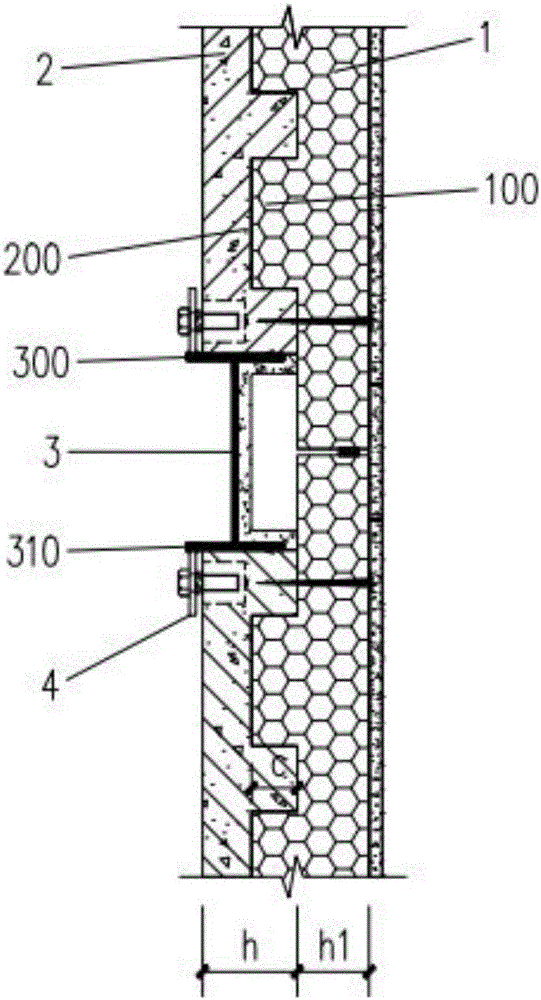

[0047] Step 2, binding steel bars on the side of the installation bumps of the insulation board, and pouring concrete on the steel bars to form a prefabricated reinforced concrete wall panel with installation grooves matching the installation bumps;

[0048] Wherein, the thermal insulation board is fixedly connected to the prefabricated reinforced concrete wall panel through the concave-convex engagement of the installation bump and the installation groove.

[0049] First use the mold with grooves to produce insulation boards wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com