Control method of underground linear motor difunctional reciprocating oil-well pump oil production device

A technology of linear motors and oil extraction devices, applied in AC motor control, pump control, control systems, etc., to reduce system collisions, automatically adjust operating positions, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

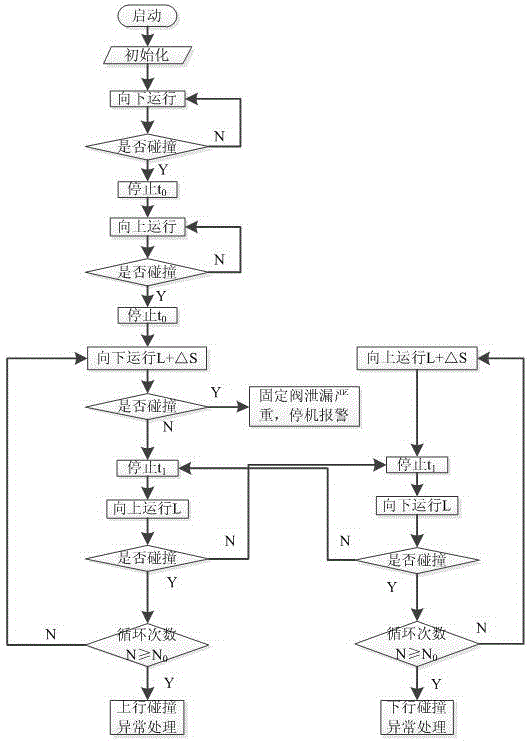

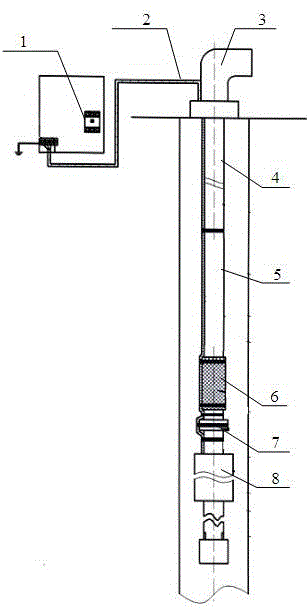

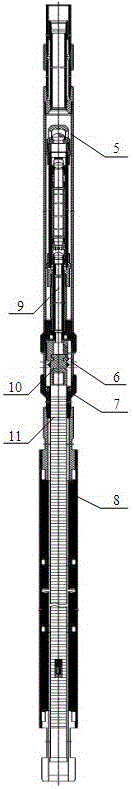

[0026] The working principle of the control method of the present invention is as follows:

[0027] The working mode of the linear motor double-acting reciprocating oil pump is intermittent operation, and the plunger of the double-acting reciprocating oil pump can be self-locked when it is not in motion. When the downhole oil production device is working, the working stroke L of the movable part is set to be less than its maximum stroke L through control. 0 , leaving a certain stroke margin ΔS near the upper and lower endpoints of the stroke, that is, L 0 =L+2ΔS, which can ensure that the moving part always runs within the maximum stroke, so it can ensure that it does not collide with the fixed part.

[0028] When the mover of the linear motor collides with the fixed part, the input current of the motor will be distorted, and the characteristics such as the periodic amplitude of the current will be different from the output set by the control program. According to this featu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com