Integrated device and method for measuring well dynamic fluid level

A liquid level measurement and dynamic technology, applied in construction and other directions, can solve the problems of short service life, lack, complex process structure, etc., and achieve the effect of novel and reasonable design, good use effect, and volume reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

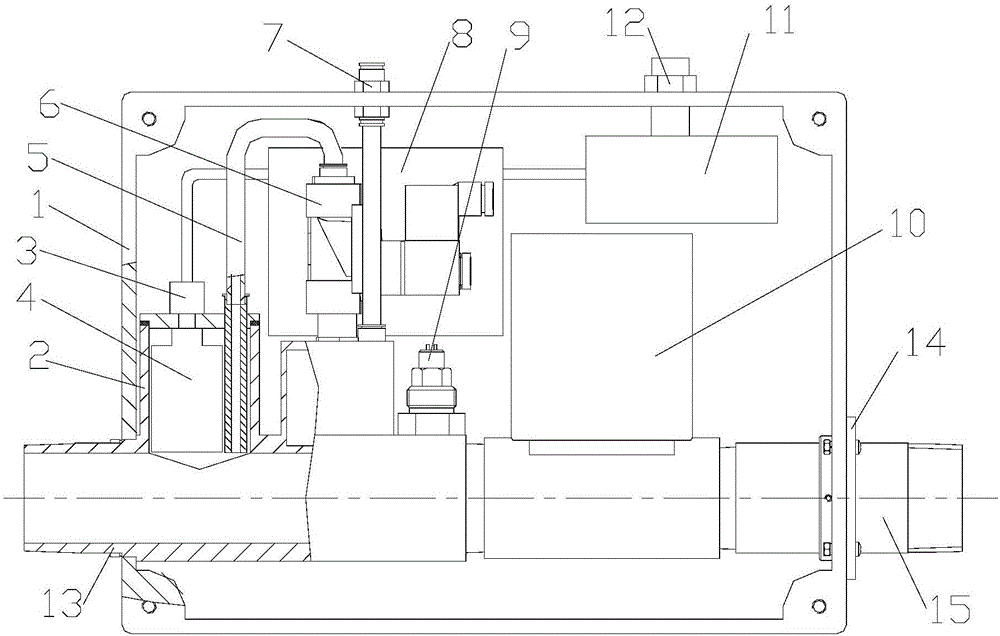

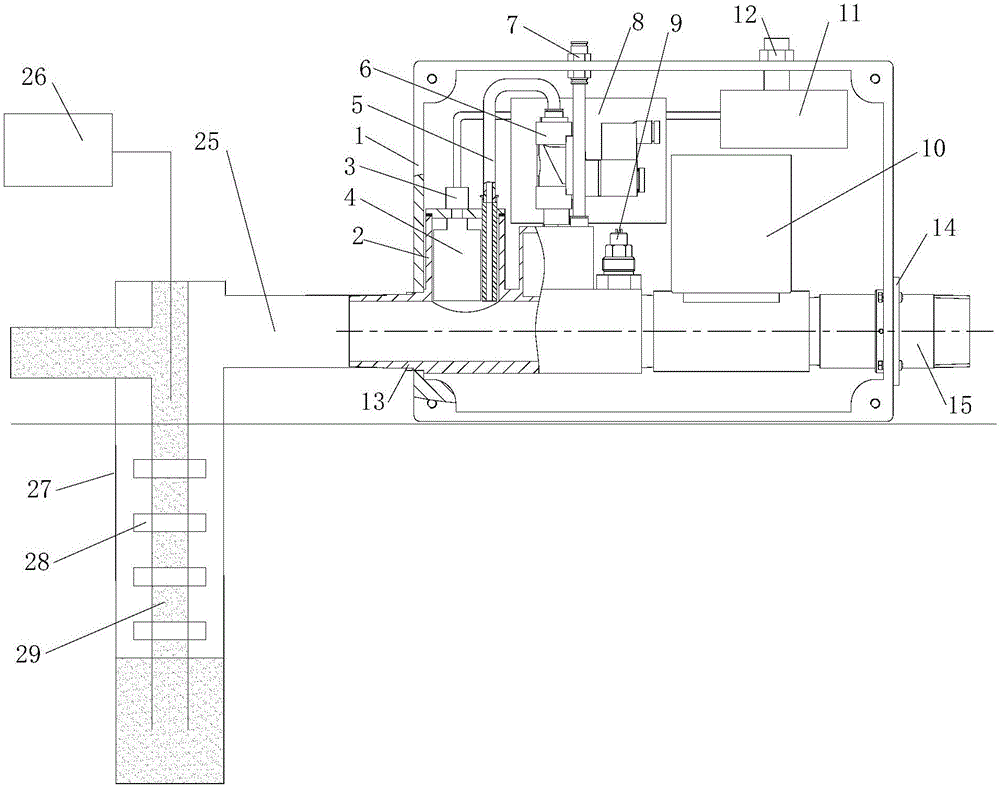

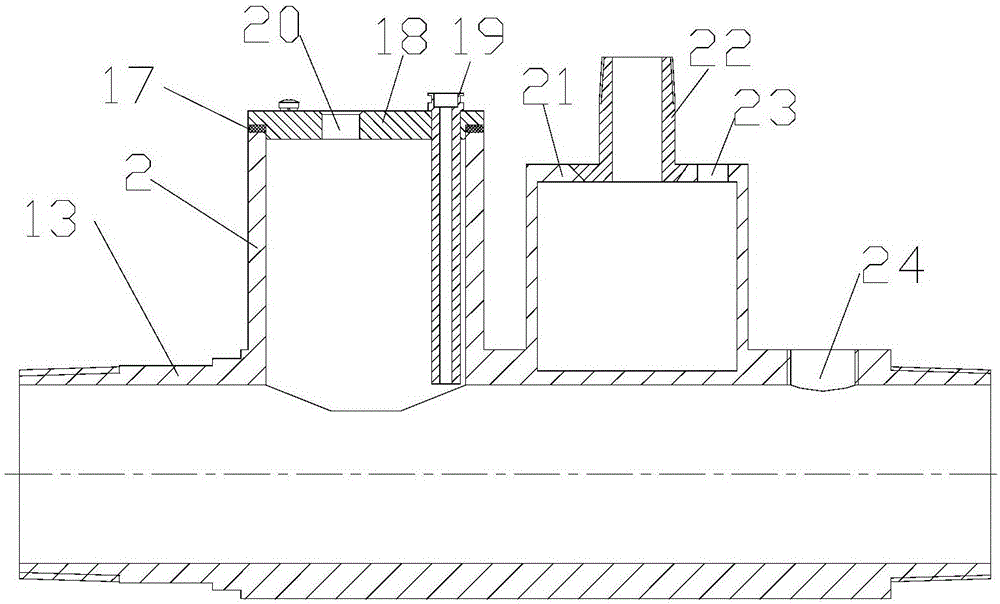

[0042] Such as Figure 1 to Figure 4 The integrated oil well dynamic liquid level measurement device shown includes an explosion-proof casing 1 installed on the casing branch pipe 25, a transmission pipe passing through the explosion-proof casing 1 and docking with the casing branch pipe 25, and an acoustic measurement device set in the explosion-proof casing 1. Mechanism and electrical control unit 11, the transmission tube is made up of a test tube 13 and an air release tube 15, the side wall of the test tube 13 is provided with a sound wave receiving air pipe 2 and a pressure measuring hole 24 communicated with the test pipe 13, the sound wave receiving air pipe 2 Closed by the installation cover 18, the installation cover 18 is provided with a microphone installation hole 20, and the position of the test tube 13 close to the sound wave receiving air pipe 2 is provided with a gas storage bin 21 integrated with the test tube 13 processing system to store gas. The bin 21 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com