Electrical imaging measuring device with emitting and reflowing inside electrode plate and method

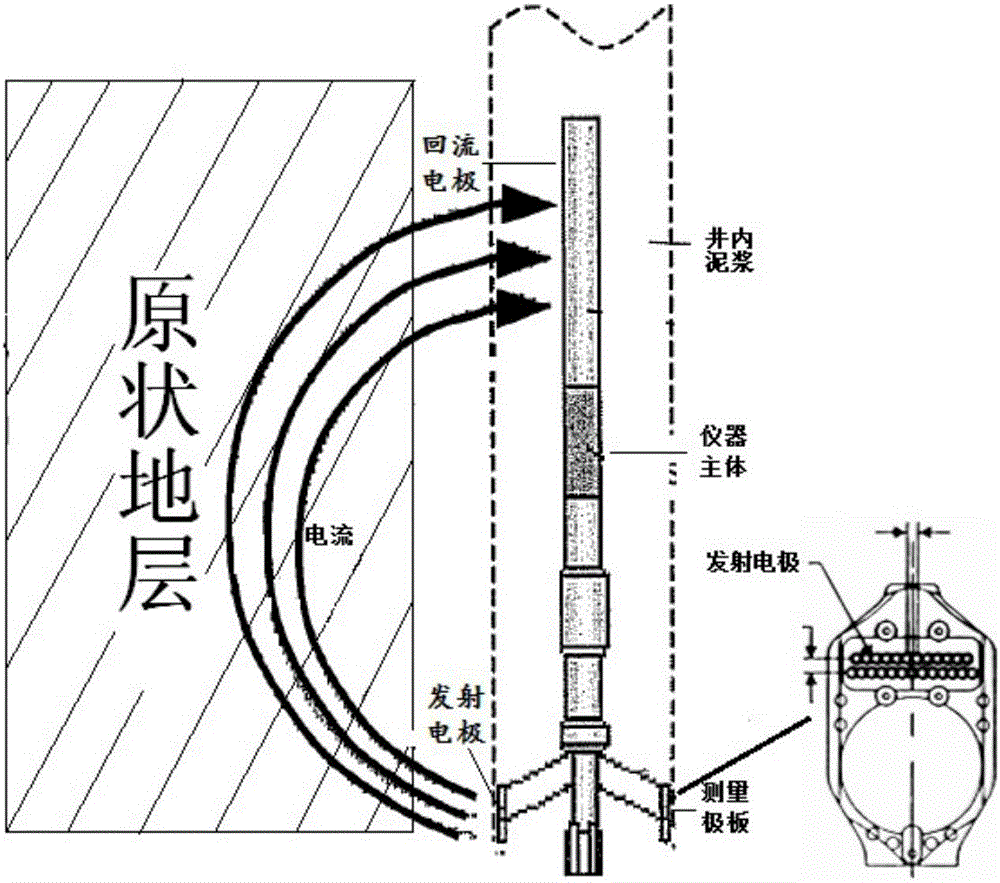

An electro-imaging and transmitting electrode technology, which is used in earth-moving drilling, wellbore/well components, etc., can solve the problem of unfavorable measurement of real information and measurement balance, inability to obtain the real electrical characteristics of the formation, and increase the difficulty of data processing and work. It can shorten the launch-return distance, increase the wellbore coverage, and reduce the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

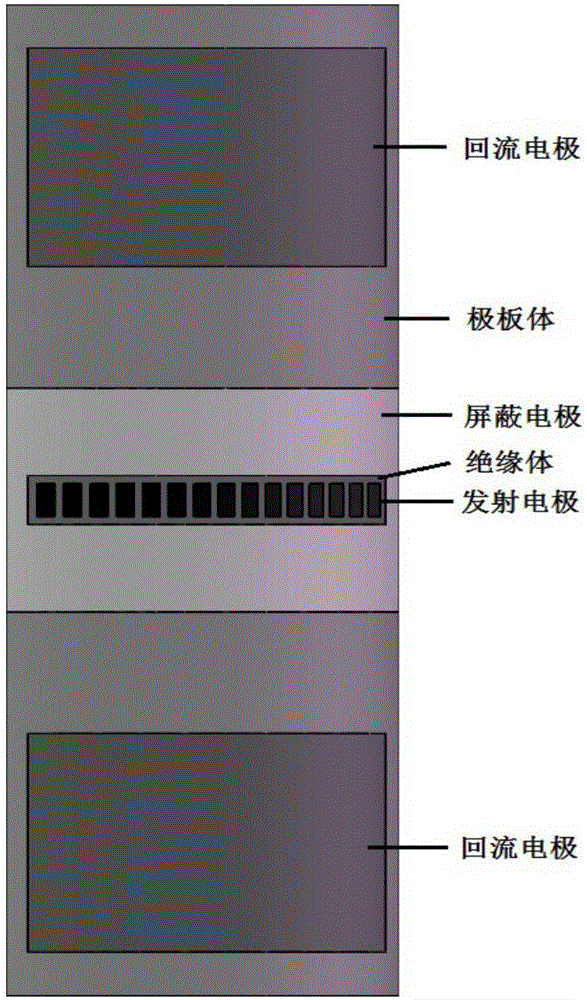

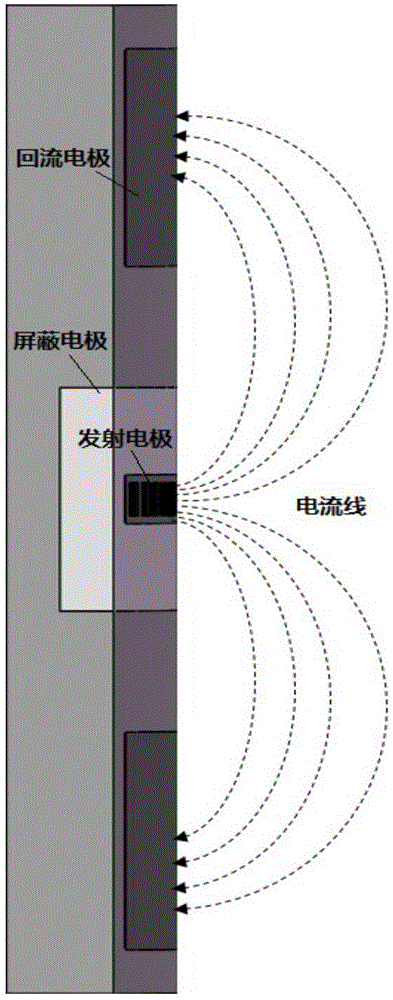

[0050] figure 2 It is the plate structure diagram of the instrument in the embodiment of the present invention, which shows the distribution position and arrangement of each electrode. The pole plate includes a group of emitter electrodes installed on the outer surface of the pole plate, and the emitter electrodes are arranged in a row and evenly distributed in the center of the pole plate. The polar plate also includes an integral shielding electrode, which is distributed around the emitter electrode and separated from the emitter electrode by an insulator. The shielding electrode is roughly flush with the outer surface of the emitting electrode, and the shielding electrode is made of a conductive material, which focuses the emitting current. The pole plate also includes an integral insulator, and the insulator is distributed between the shielding electrode and the emitting electrode, and plays an insulating and separating role on the emitting electrode and the shielding el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com