Variable-speed and constant-frequency power generation system and method based on screw expander

A technology of screw expander and constant frequency power generation, which is applied in the control system, control generator, machine/engine, etc., can solve the problems of consuming grid reactive power, grid power factor drop, large inrush current, etc., and achieve convenient grid connection The effects of decoupling, high power generation, and strong ability to adapt to gas flow fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

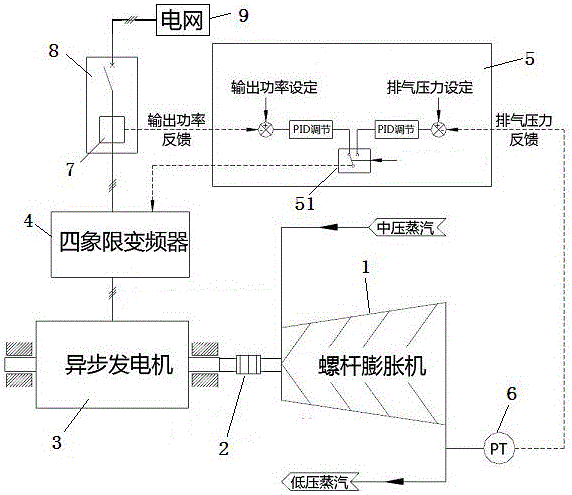

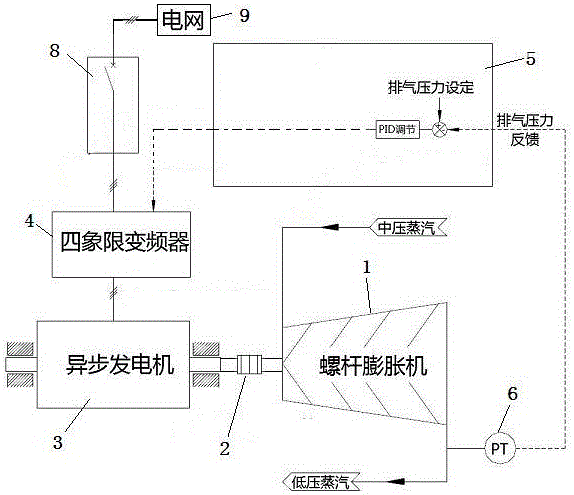

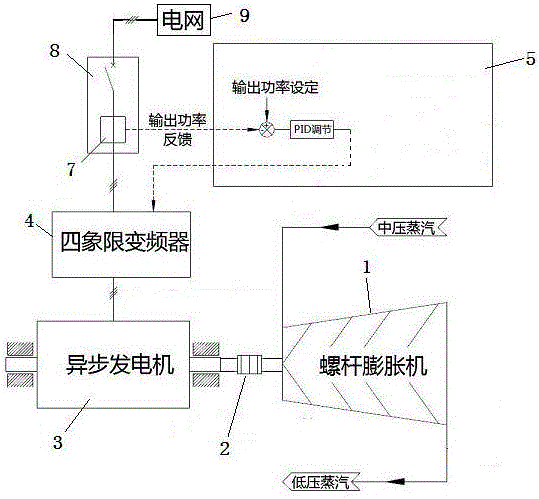

[0025] see figure 1 . According to the first embodiment of the present invention, a screw expander variable-speed constant-frequency power generation system includes a screw expander 1, a transmission mechanism 2, an asynchronous generator 3, a four-quadrant frequency converter 4, a controller 5, a pressure feedback device 6 and an output Power feedback device 7.

[0026] The output shaft of the screw expander 1 is connected with the rotor of the asynchronous generator 3 through the transmission mechanism 2 . In a specific embodiment, the transmission mechanism 2 is a shaft coupling. In another specific embodiment, the transmission mechanism 2 includes a first coupling, a second coupling and a gear box. The output shaft of the screw expander 1 is connected with the input shaft of the gearbox through the first coupling, and the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com