Direct combustion heating type supercritical carbon dioxide power cycle system and method

A carbon dioxide, circulating system technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problem of a large proportion of the cost of air separation devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

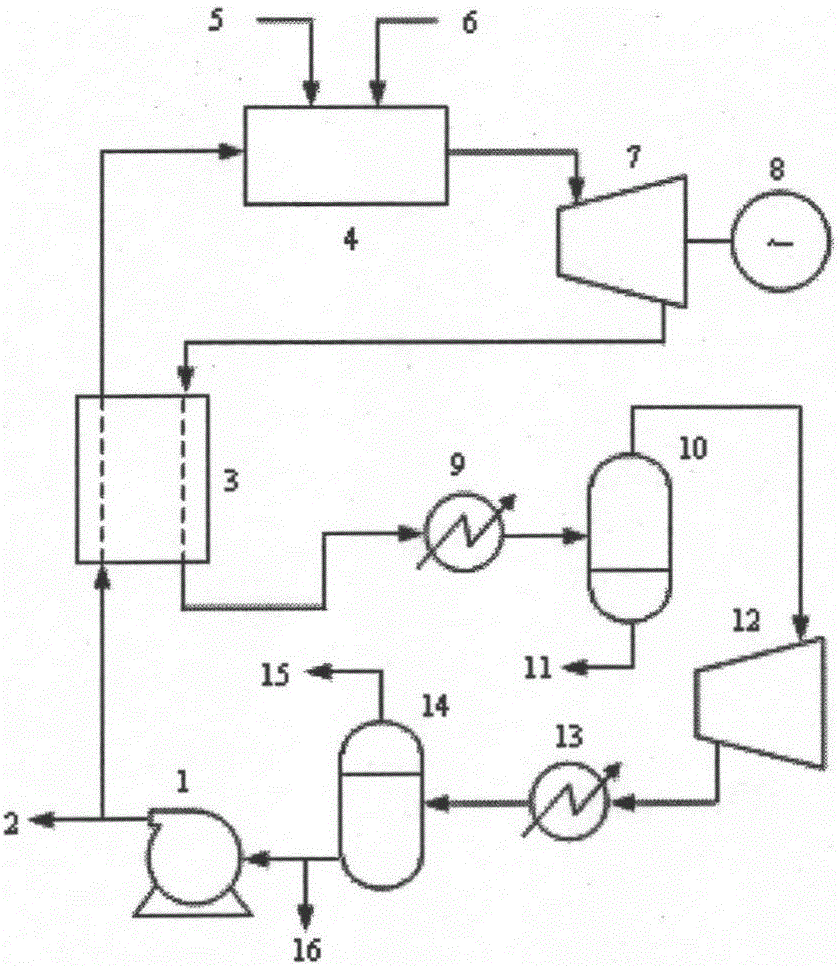

[0034] like figure 1 As shown, a direct combustion heating supercritical carbon dioxide power cycle system provided by the present invention includes a pump 1, the outlet of the pump 1 is connected to the inlet of the low-pressure side of the regenerator 3, and the outlet of the low-pressure side of the regenerator 3 is connected in turn The first cooler 9, the water separator 10, the compressor 12, the second cooler 13, the gas separator 14, the bottom of the water separator 10 is provided with a drain port 11, and the top of the gas separator 14 is provided with an exhaust port 15, The bottom is connected to the inlet of the pump 1; the high-pressure side of the regenerator 3 forms a circuit through the burner 4 and the turbine 7 in turn. The outlet of the pump 1 is provided with a carbon dioxide discharge port 1 2 , and the inlet is provided with a carbon dioxide discharge port 2 16 . The various devices are connected by pipelines, and valves and instruments can be arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com