Cooling water pump for internal combustion engine and production process of cooling water pump

A technology for cooling water pumps and internal combustion engines, which is applied in the cooling of engines, liquid fuel engines, components of pumping devices for elastic fluids, etc. , reduce the impact, improve the effect of pump flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

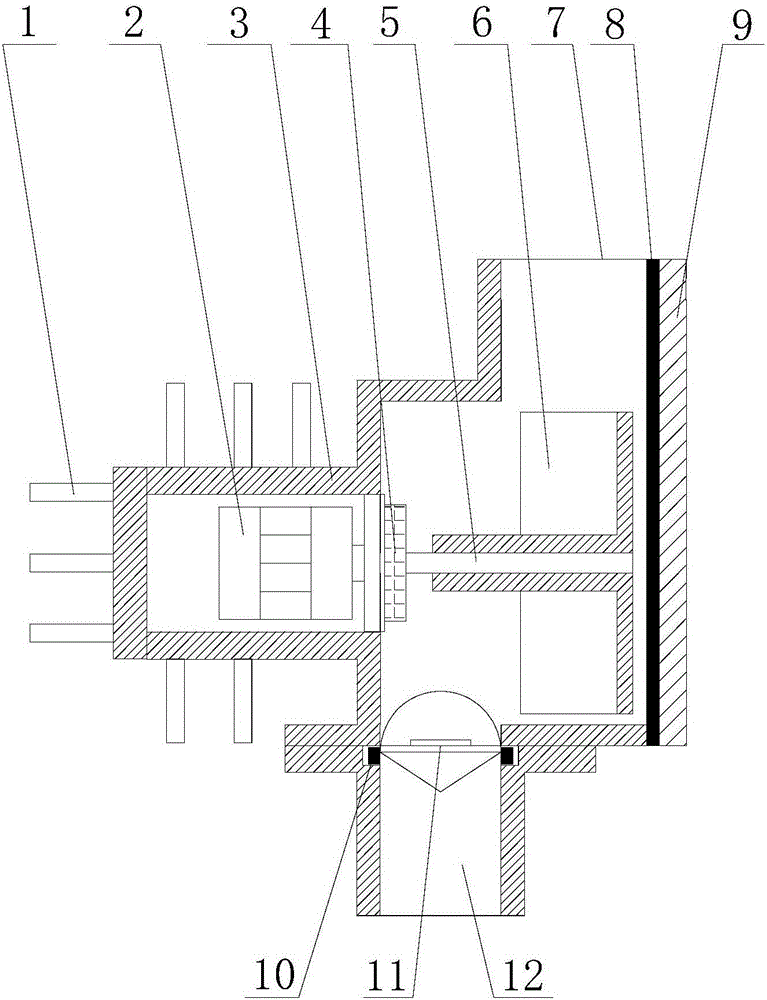

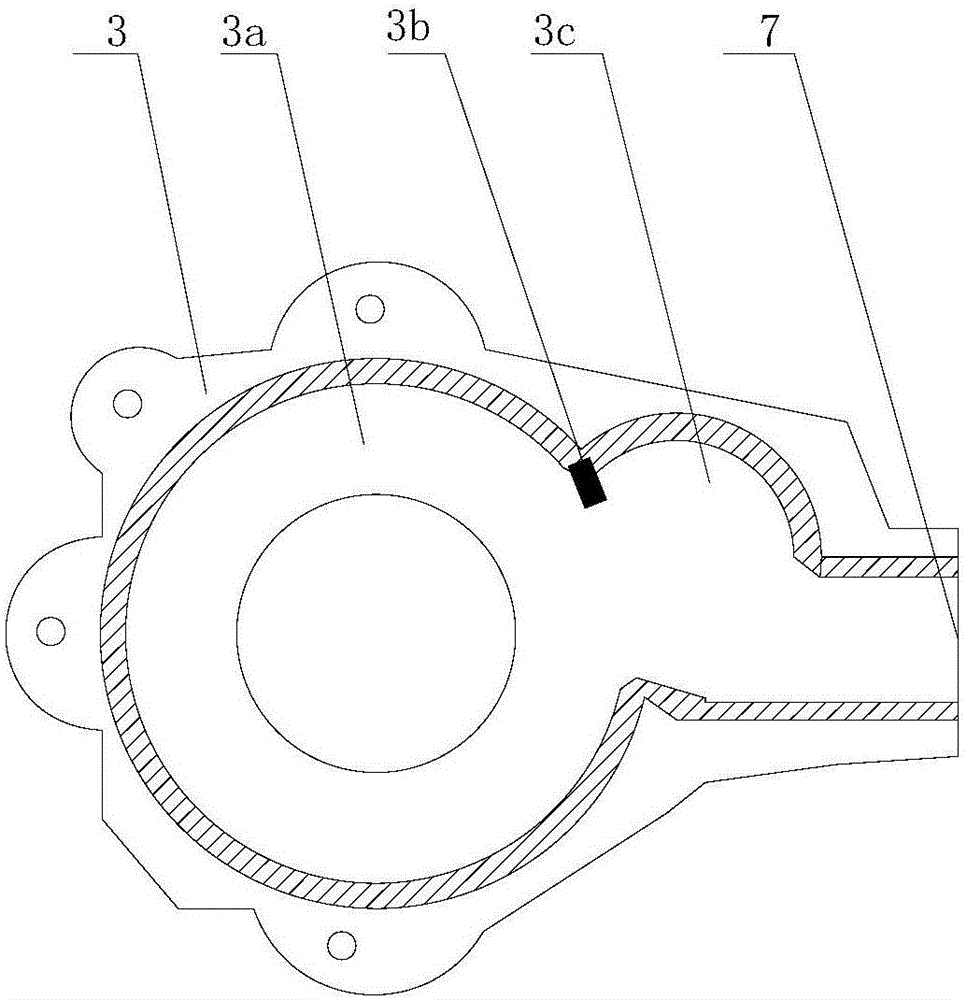

[0070] This embodiment provides a cooling water pump for an internal combustion engine, such as figure 1 , 2 As shown in and 3, it includes a water pump housing 3, a rotating shaft 5, a cover plate 9 and an impeller 6. The water pump housing 3 is formed with a cavity 3a, the rotating shaft 5 is installed in the middle of the cavity 3a through a bearing, and the impeller 6 can rotate along its own axis. Installed on the rotating shaft 5, the cover plate 9 is affixed to the side of the water pump housing 3 that is formed with the cavity 3a; the water pump housing 3 is provided with a water inlet 12 and a water outlet 7, and the water inlet 12 of the water pump housing 3 is provided with In the temperature control valve 11, a partition tongue 3b is formed near the water outlet 7 in the cavity 3a, and a vortex chamber flow channel 3c is formed between the partition tongue 3b and the water outlet 7, and the vortex chamber flow channel 3c is arc-shaped;

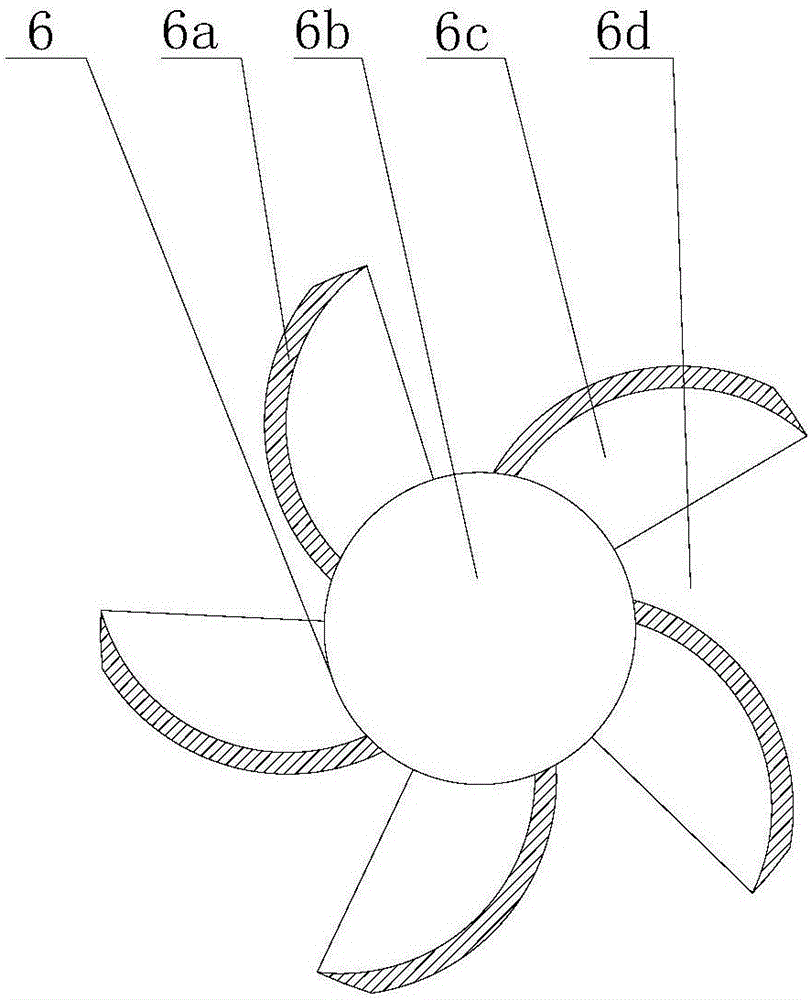

[0071] The impeller 6 incl...

Embodiment 2

[0103] This embodiment provides a kind of cooling water pump for internal combustion engine, comprising water pump housing 3, rotating shaft 5, cover plate 9 and impeller 6, water pump housing 3 is shaped on cavity 3a, rotating shaft 5 is installed in the middle part of cavity 3a through bearing, impeller 6 is installed on the rotating shaft 5 that can rotate along its own axis, and the cover plate 9 is fixedly connected with the side of the cavity 3a of the water pump housing 3; the water pump housing 3 is provided with a water inlet 12 and a water outlet 7, and the water pump housing 3 The water inlet 12 is provided with a temperature control valve 11, and a partition tongue 3b is formed near the water outlet 7 in the cavity 3a, and a vortex chamber flow channel 3c is formed between the partition tongue 3b and the water outlet 7, and the vortex chamber flow channel 3c is Arc type;

[0104] The impeller 6 includes a hub 6b, a disc 6c and a blade 6a, the hub 6b is fixed to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com