Electronic throttle valve of engine of range-increasing type electric vehicle

An electronic throttle, electric vehicle technology, applied in the direction of engine control, machine/engine, electrical control, etc., can solve the problems of high control precision, achieve precise control of speed, reduce heat generation and power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

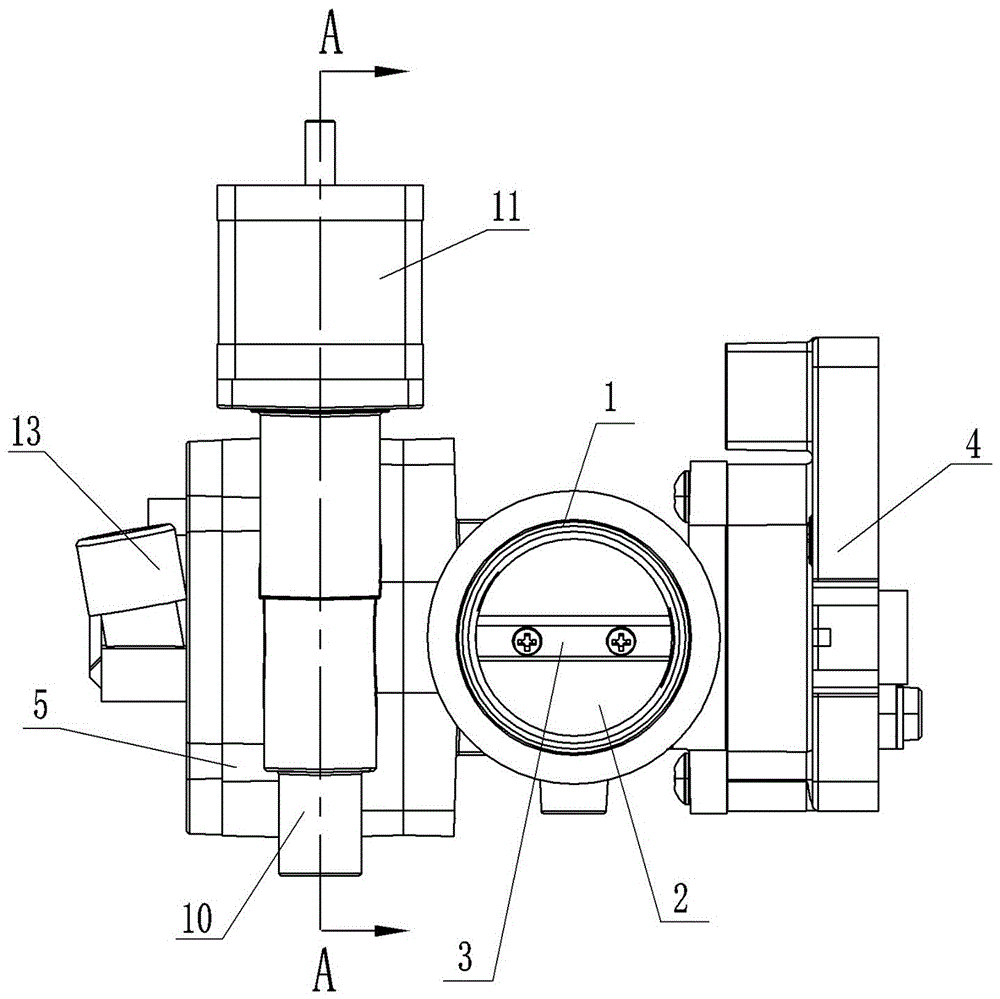

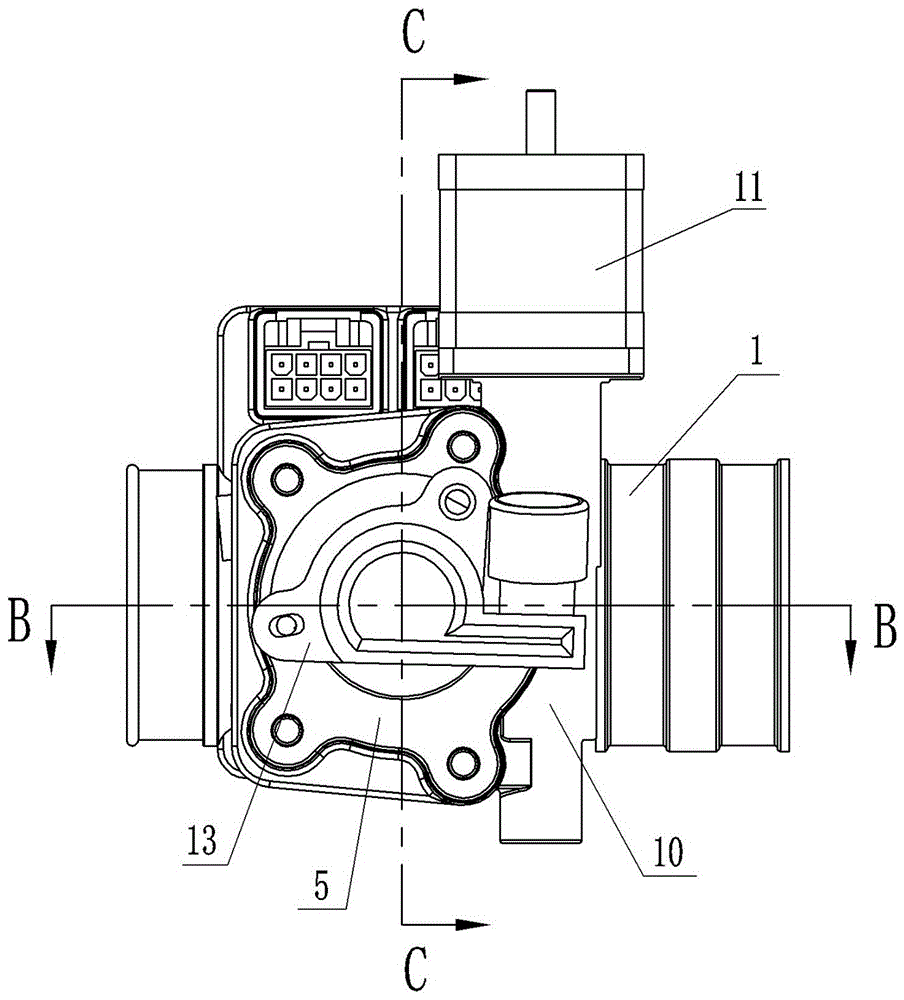

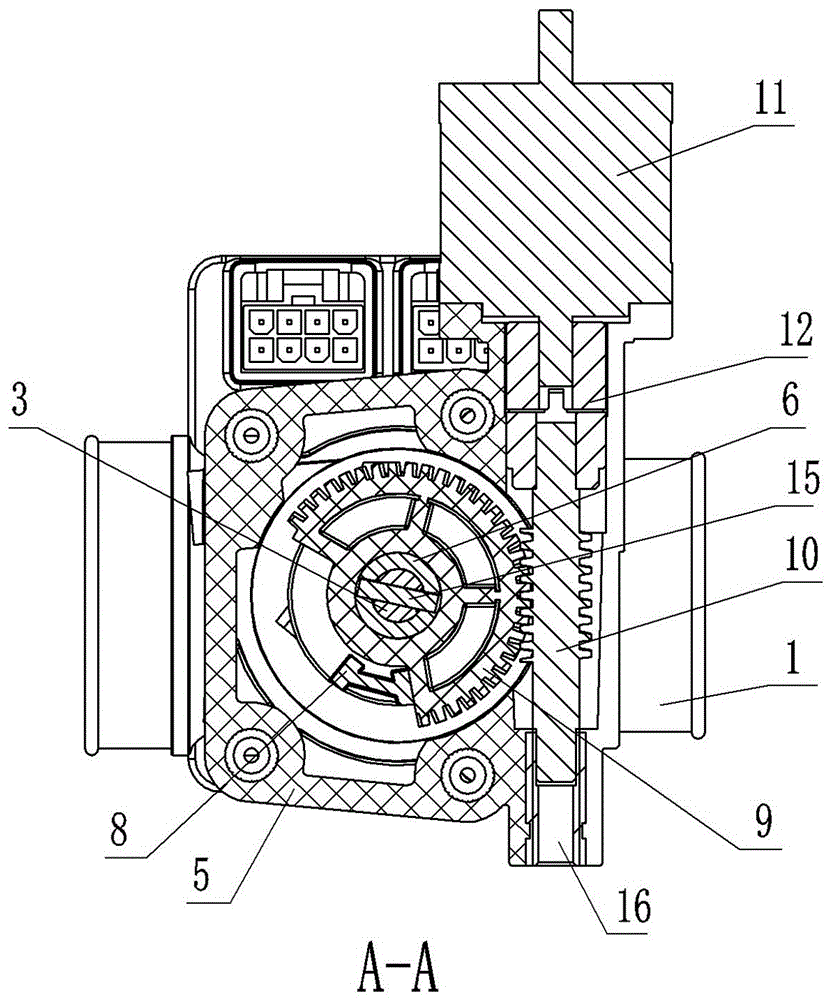

[0025] The electronic throttle valve of the extended-range electric vehicle engine of the present invention includes an intake pipe 1, a valve plate 2, a throttle shaft 3, an electric injection ECU 4 and a worm gear box 5, and the electric injection ECU 4 is fixedly arranged on one side of the intake pipe 1, and the worm gear The box body 5 is fixedly arranged on the other side of the intake pipe 1, the throttle shaft 3 is installed vertically on the intake pipe 1 inside the worm gear box 5 and the intake pipe 1, and the valve plate 2 is fixed on the throttle shaft 3 inside the intake pipe 1, so that A worm gear seat 6 is fixed on the throttle shaft 3 inside the worm gear box 5, and a return spring 7 is installed on the periphery of the throttle shaft 3 between the worm gear seat 6 and the intake pipe 1; Block 8, worm wheel seat 6 is set with worm wheel 9 for sliding, and worm wheel 9 is provided with notch groove corresponding to limit block 8, the height of limit block 8 matc...

Embodiment 2

[0030] The same as embodiment 1 will not be repeated, the difference is:

[0031] The driving motor is fixedly connected directly with the worm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com