Direct wallboard radiation heating system employing buried gravity heat pipes

A gravity heat pipe and radiant heating technology, which is applied in heating systems, geothermal power generation, and heat collectors that use underground pools to accumulate working fluids, etc., can solve violations of energy saving and consumption reduction, increase operating energy consumption, and increase the hydraulic power of the heating system Unbalance and other problems, to achieve the effect of no operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

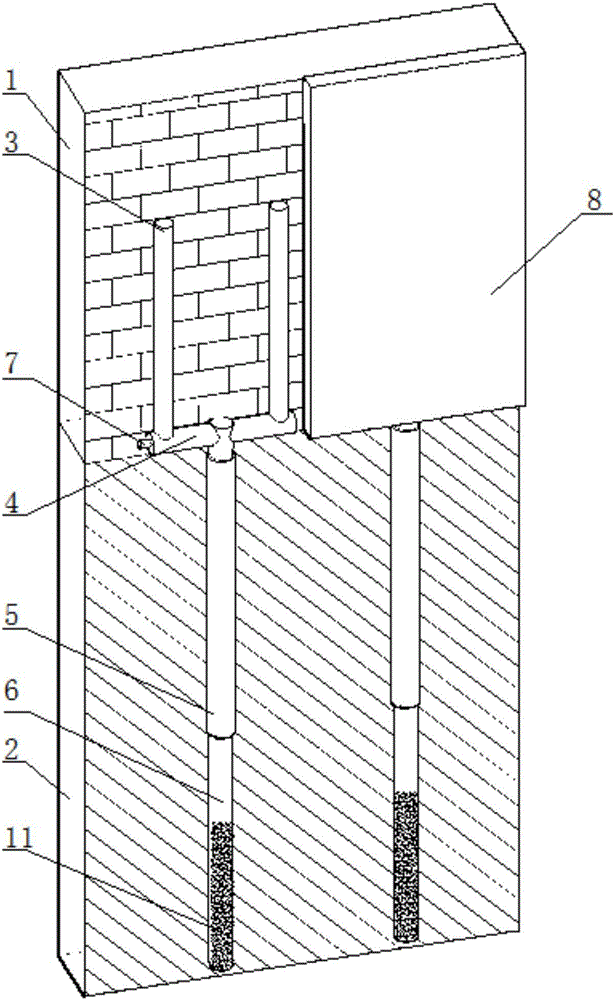

[0023] Such as figure 1 As shown, the heating system includes multiple groups of buried gravity heat pipe heat dissipation units, each heat dissipation unit includes a condensation section 3, a heat transfer section 5, an evaporation section 6, a liquid injection port 7, and a phase change liquid 11; each heat dissipation unit has Two or three condensing sections 3 are connected to the horizontal main pipe 4 by welding; the horizontal main pipe 4 and the heat transfer section 5 are connected by a tee; The evaporation section 6 and the heat transfer section 5 are vertically placed in the soil, wherein the evaporation section 6 is placed in the constant temperature layer of the soil 2 at a depth of 10m-15m for direct absorption of shallow geothermal energy, and the heat transfer section 5 is placed in the soil at a constant temperature Between the floor and the ground, there is a polyurethane insulation layer; the condensation section 3 and the horizontal main pipe 4 are placed ...

Embodiment 2

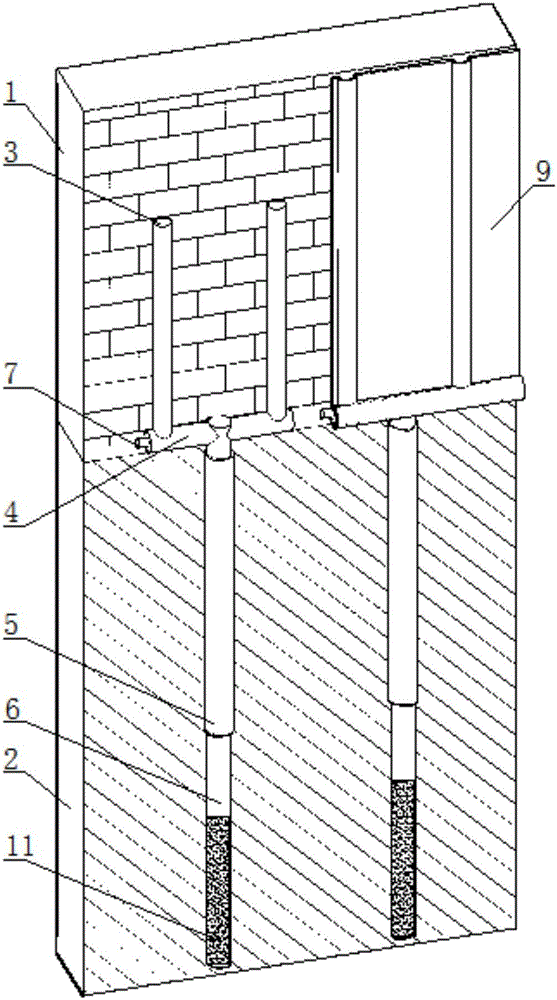

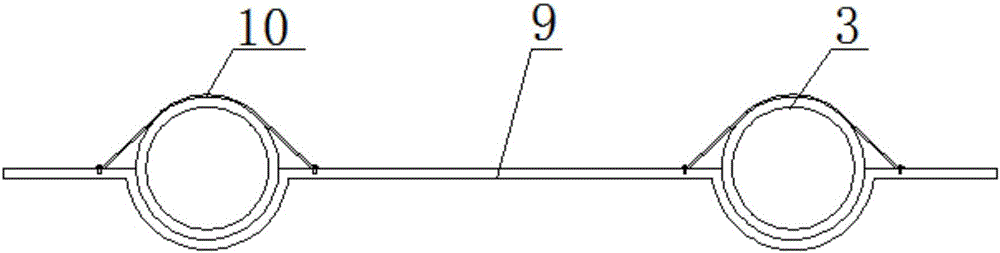

[0025] Such as figure 2 As shown, in this embodiment, the plastering layer 8 in the wall is replaced by an aluminum plate 9 with a groove, and the heat release section 3 of the heat pipe is embedded in the groove of the aluminum plate, and fixed by a U-shaped clamp 10, U The type clamp 10 and the aluminum plate 9 are connected by self-tapping screws, and the aluminum plate 9 and the wall 1 are fixed by screw connection. Other positions are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com