Baffle rod type preheater for high-pressure boiler water and chemical reaction device

A high-pressure boiler and preheater technology, which is applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc. Low thermal efficiency and other problems, to achieve the effect of reducing material requirements and manufacturing difficulty, eliminating hidden dangers of high temperature stress, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

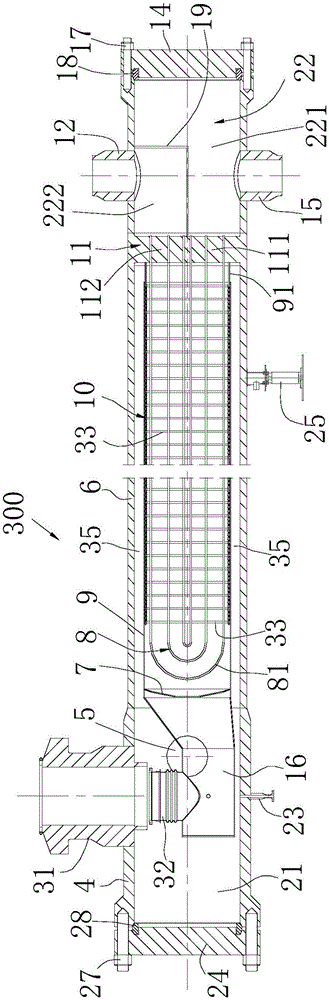

[0024] refer to figure 1 , a high-pressure boiler water baffle rod preheater 300, which includes a shell 6 closed at both ends, the shell 6 is cylindrical, a front end cover 24 is installed at one end of the shell 6, and a rear end cover is installed at the other end 14. Front-end cover bolts 27 fasten the front-end cover 24 to one end of the casing, and a front-end seal 28 is installed between the front-end cover 24 and the end surface of the casing. The rear end cover bolts 17 fasten the rear end cover 14 on the other end of the casing, and a rear end seal 18 is installed between the rear end cover 14 and the end surface of the casing.

[0025] A tube plate 11 is arranged in the shell 6, and the tube plate 11 divides the inner cavity of the shell 6 into a heat exchange cavity and a water cavity 22; Divided into a water inlet chamber 221 and a water outlet chamber 222 that are not connected to each other, the partition plate 19 divides the tube plate 11 into two parts: the w...

Embodiment 2

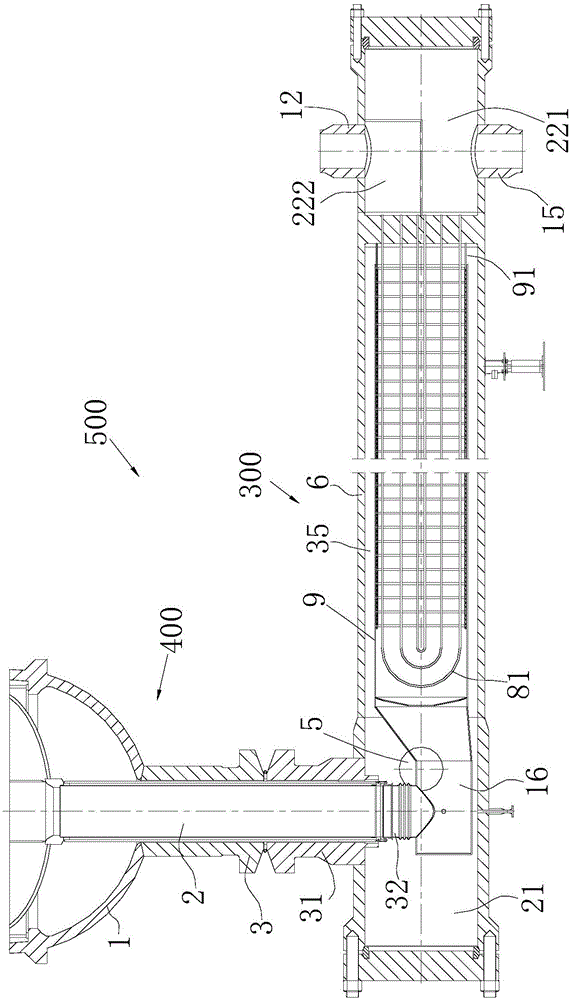

[0034] see figure 2 , a chemical reaction device 500 for an exothermic reaction, which includes the high-pressure boiler water baffle rod preheater 300 described in Embodiment 1 and a reactor 400, and the shell 1 of the reactor 400 is connected by a connecting flange 3 To the inlet sleeve 31 of the preheater 300, the reaction gas outlet pipe 2 of the reactor 400 is connected to the gas inlet 32 of the preheater 300, and a metal soft joint is installed between the reaction gas outlet pipe 2 and the gas inlet 32 .

[0035] The reaction gas that has completed the reaction in the reactor 400 enters the preheater 300 through the reaction gas outlet pipe 2 and the gas inlet 32, and then the reaction gas enters the tube bundle sleeve 9 through the high-temperature inner header 16, and passes through the tube bundle sleeve 9 The internal reactant gas passes through the gaps between the U-shaped heat exchange tubes 81, exchanges heat with the cooling water in the U-shaped heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com