Marine diesel engine sliding main bearing thermoelectricity signal calibration device and calibration method

A marine diesel engine and calibration device technology, applied in mechanical bearing testing, material defect testing, etc., can solve problems such as main bearing wear, eccentric shaft box melting and breaking, economic loss, etc., to achieve the effect of enhancing adaptability and ensuring smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

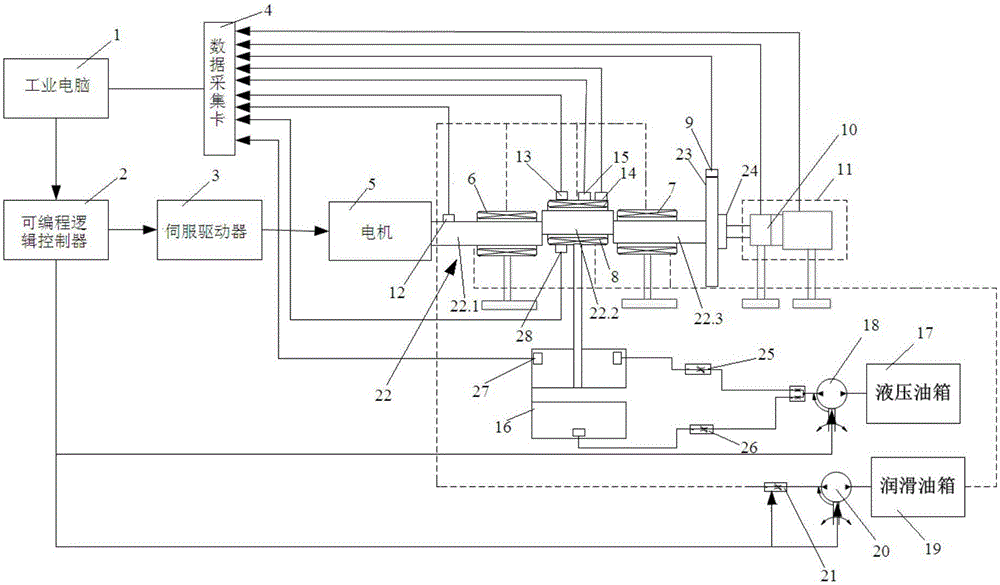

[0047] The thermal electric signal calibration device of the sliding main bearing of the marine diesel engine of the present invention comprises an industrial computer 1, a programmable logic controller 2, a servo driver 3, a data acquisition card 4, a motor 5, a front support bearing 6, a rear support bearing 7, and an experimental bearing 8. Speed sensor 9, thermoelectric sensor 11, torque sensor 12, tile back temperature sensor 13, lubricating oil temperature sensor 14, lubricating oil pressure sensor 15, hydraulic cylinder 16, hydraulic oil tank 17, hydraulic pump 18, lubricating oil tank 19, lubricating oil pump 20. Lubricating oil heater 21, hydraulic sensor 27 and displacement signal sensor 28;

[0048] Wherein, the signal output terminal of the industrial computer 1 is connected to the signal input terminal of the programmable logic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com