Electric bus composite braking hardware-in-the-loop test platform and method based on electronic-controlled braking system

A technology for electronically controlled braking and electric buses, which is applied in general control systems, control/adjustment systems, test/monitoring control systems, etc., and can solve problems such as joint testing of electronically controlled braking systems and regenerative braking systems of electric buses. , to achieve the effect of repeated tests, saving test funds, and fewer test personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0053] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

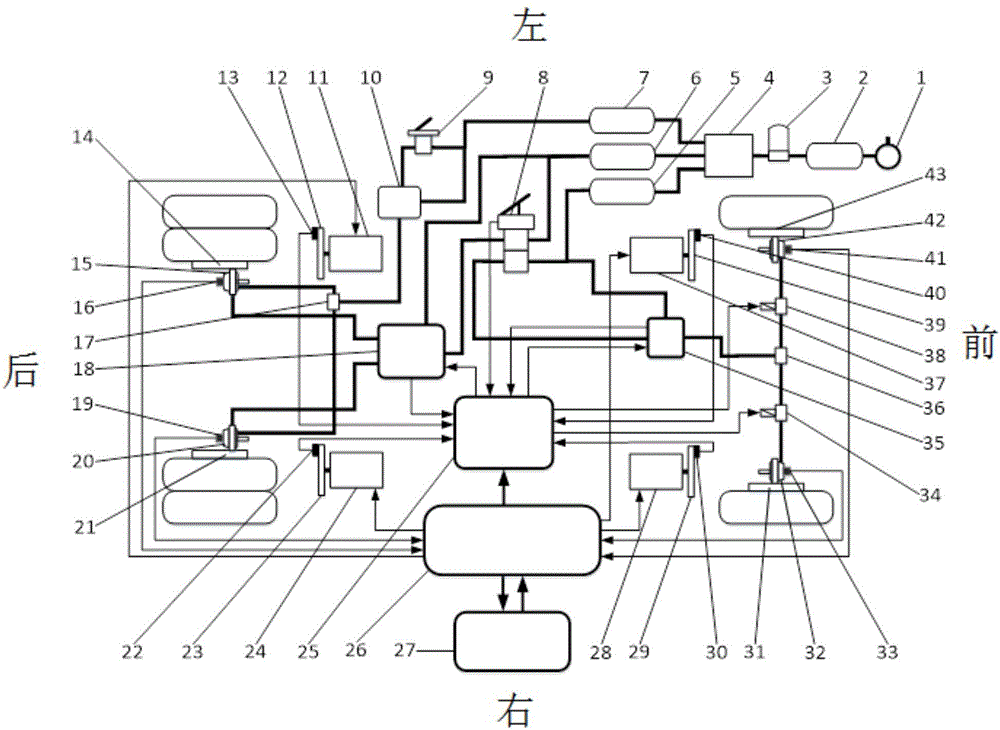

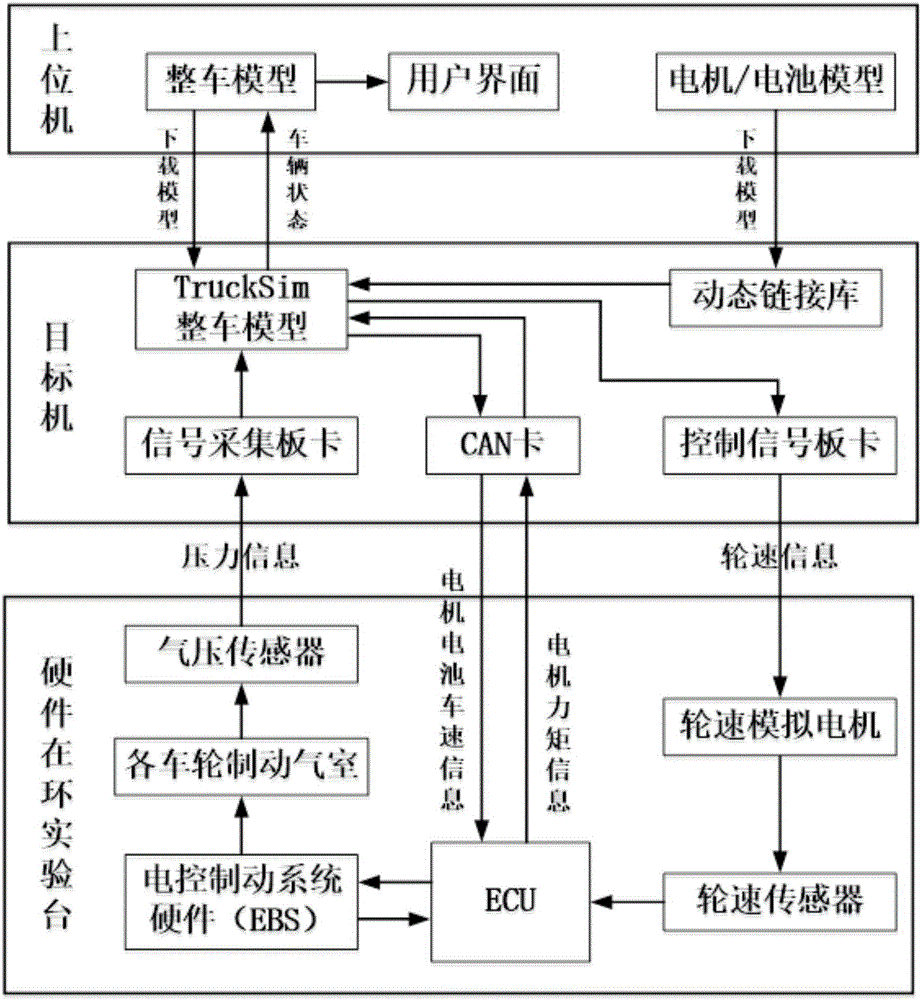

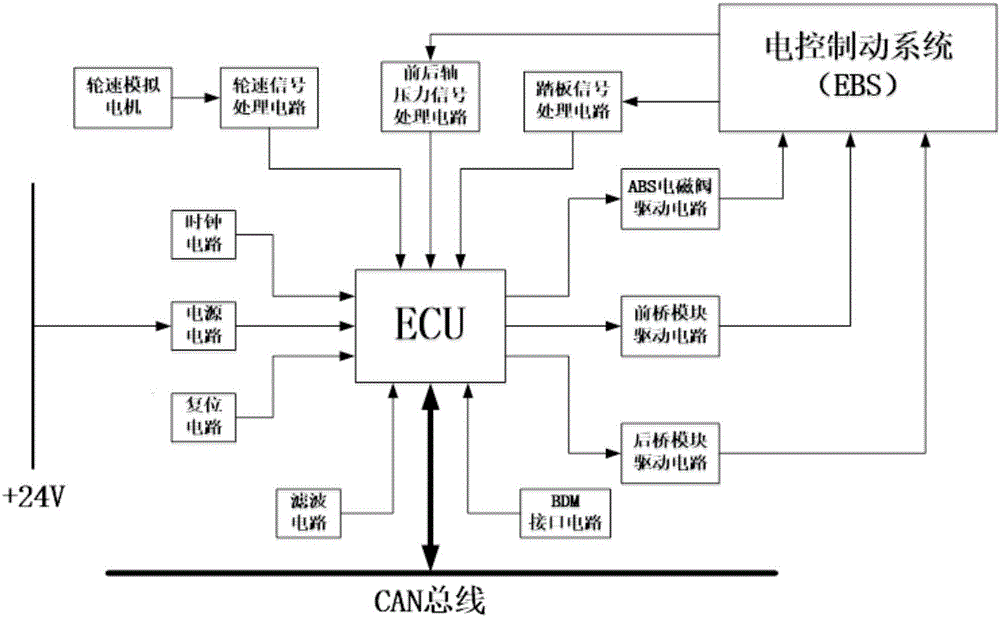

[0054] refer to figure 1 , the invention discloses a hardware-in-the-loop test platform for composite braking of electric passenger cars based on an electronically controlled braking system. The controller 25, the upper computer 27 and the target computer 26 are composed.

[0055] The air making assembly includes an air compressor 1 , a wet air storage tank 2 , an air dryer 3 , a four-circuit protection valve 4 , a front axle air storage tank 5 , a rear axle air storage tank 6 and a parking brake air storage tank 7 .

[0056] The third-generation electronically controlled braking system (EBS) includes master brake valve 8, model WABCO 4800021030; front axle pressure control module 35, model WABCO 4801067010; rear axle pressure control module 18, model WABCO4801067010; left fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com