Nondestructive inspection device for wire rope

A non-destructive testing and wire rope technology, applied in the direction of material magnetic variables, etc., can solve the problems of missed judgment, confusion of other signals of MFL signals, interference of MFL signals, etc., and achieve the effect of improving the signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

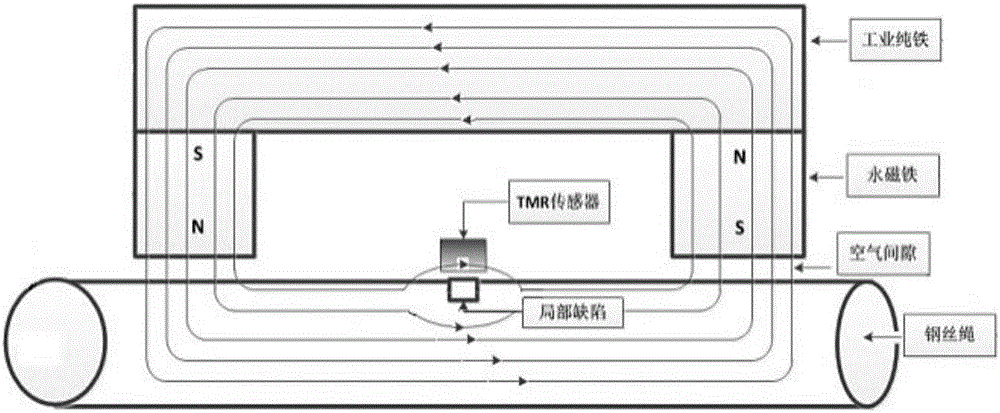

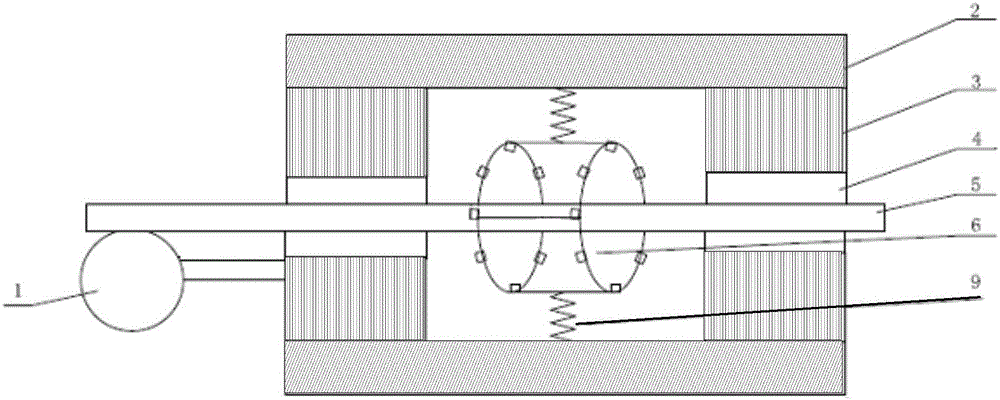

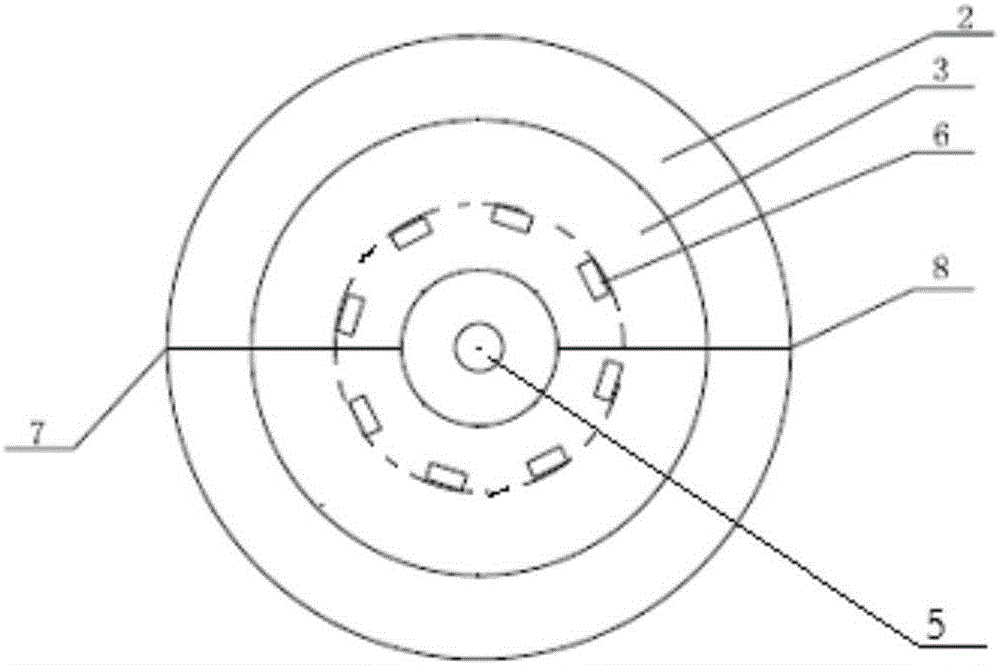

[0028] Fig. 2(a) and Fig. 2(b) are schematic diagrams of the principles of the non-destructive testing device for steel wire ropes of the present invention. As shown in the figure, the device includes: an excitation component, a sensor component, a data processing module and an angle encoder 1 .

[0029] The excitation assembly is used to provide a uniform magnetic field. In this embodiment, the excitation assembly is composed of a cylindrical magnetic conductor 2 and two annular permanent magnets 3 . Wherein, the cylindrical magnetizer 2 is made of industrial pure iron, and the annular permanent magnet 3 is made of permanent magnets. Two annular permanent magnets 3 are installed at both ends of the inner wall of the cylindrical magnetizer 2 , and an air gap 4 is provided in the middle of the annular permanent magnets 3 . The steel wire rope 5 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com