Fiber grating with pre-distortion structure and manufacturing equipment and technology of fiber grating

A technology of twisted structure and fiber grating, applied in cladding fiber, optical waveguide light guide, optics, etc., can solve the problems of complex manufacturing process of fiber grating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

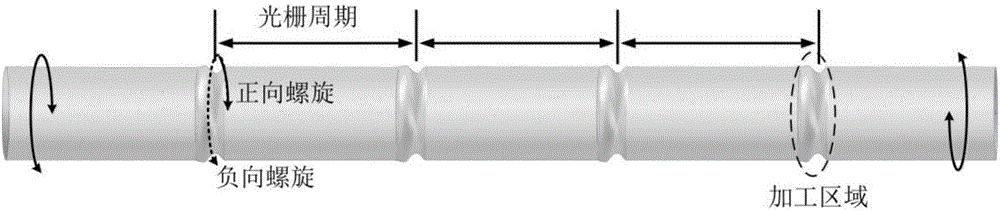

[0035] As a first embodiment of the present invention, such as figure 1 As shown, the present invention provides a fiber grating with a pre-twisted structure:

[0036] The fiber grating includes several grating periods, and the processing area of each grating period has a pre-twisted structure with positive helical deformation or a pre-twisted structure with negative helical deformation;

[0037] The several grating periods form a long-period fiber grating with a positive helical deformation pre-twist structure, or a long-period fiber grating with a negative helical deformation pre-twist structure, or a long-period fiber grating with a positive and negative helical deformation pre-twist structure.

[0038] like figure 1 The shown fiber grating with a pre-twisted structure is divided into multiple grating periods according to a certain grating pitch division method. In this embodiment, the grating pitch is generally defined to be about 300 μm to 700 μm, and the length of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com