Direct-current short-circuit prevention electric connection sheet

An electrical connection piece, anti-short-circuit technology, applied in circuits, electrical components, emergency protection devices, etc., can solve the problems of temperature rise, isolation, and heating of conductive parts in small-area sections, so as to reduce connection heat, reduce The effect of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

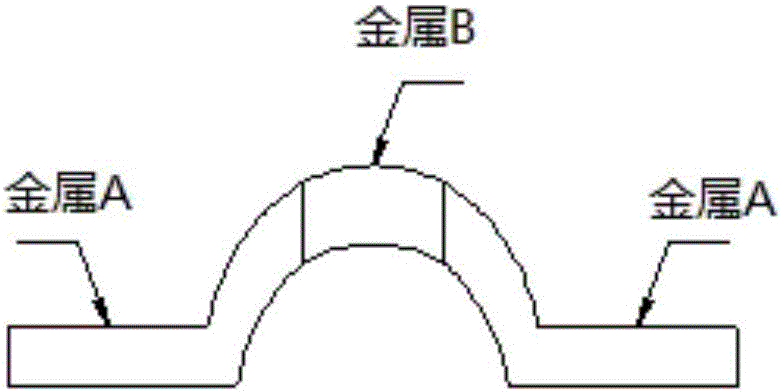

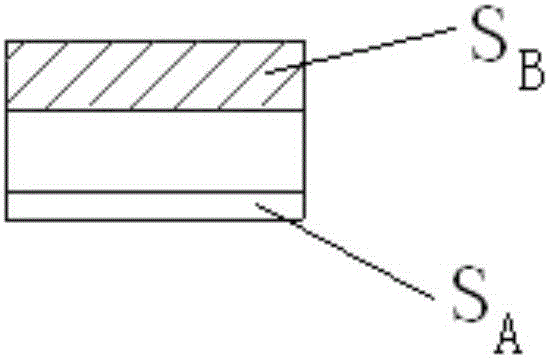

[0028] This embodiment includes two metal sheets A with the same thickness, such as Figure 1-Figure 2 The shape shown forms an arch at the junction, and through thickening or multi-layering, the thickness gradually increases from the arch section to the junction until it is the same thickness as the metal sheet B, and there is a piece of metal sheet B in the middle, whose thickness is the same as that of the metal sheet B The joints of sheet A are the same, and its equivalent rated overcurrent capacity is the same as that of the straight part of metal sheet A. The melting temperature is much lower than that of metal sheet A. The three metal sheets are connected together by electroplating or welding, and then the surface is electroplated with nickel. Or use it as an integrated electrical connection piece after tin treatment.

[0029] Cross-sectional area ratio calculation formula: ImA×SA=ImB×SB

[0030] Among them, ImA is the rated ampacity of metal A, ImB is the rated ampacit...

Embodiment 2

[0035] This embodiment provides a DC short-circuit proof electrical connector, in which multiple overcurrent units in the circuit are connected in series, and the connectors are used to connect each unit.

[0036] The two ends of the connection piece are copper nickel-plated metal pieces, which can effectively reduce the contact resistance of the contact surface and reduce the connection heat.

[0037] The rated overcurrent capability of the two metals is the same, ensuring the overall rated overcurrent capability.

[0038] When a circuit short circuit occurs, the intermediate metal (such as nickel, tin, aluminum, etc.) has a lower melting temperature than the connecting metal (such as copper or copper alloy) and the metal sheet will automatically fuse to protect the circuit.

[0039] Explosion-proof treatment is not required when the connecting piece is fused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com