Novel microstrip line packaging structure of substrate integrated gap waveguide

A technology of substrate integration and gap waveguide, applied in the field of electronics, can solve problems such as no public reports, achieve the effects of reducing space radiation, solving radiation loss and plane wave, and wide bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described in detail below in combination with specific embodiments.

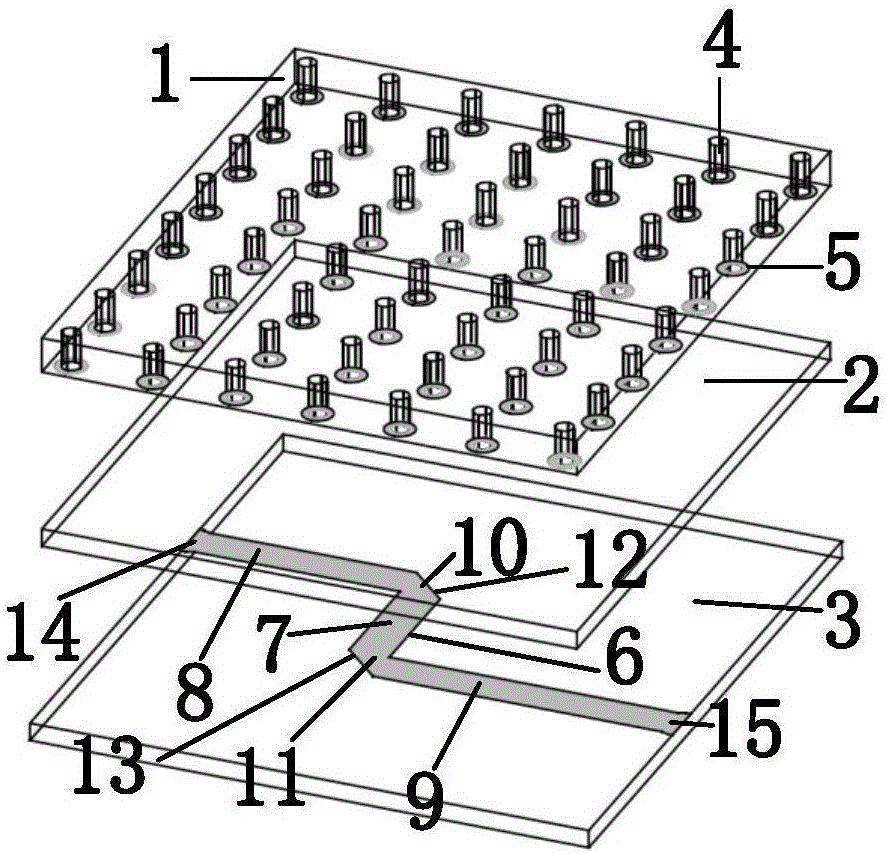

[0038] Such as Figure 1-6 As shown, a new substrate-integrated gap waveguide packaged microstrip line structure, including: a top dielectric board (1), a middle dielectric board (2), and a bottom dielectric board (3), wherein:

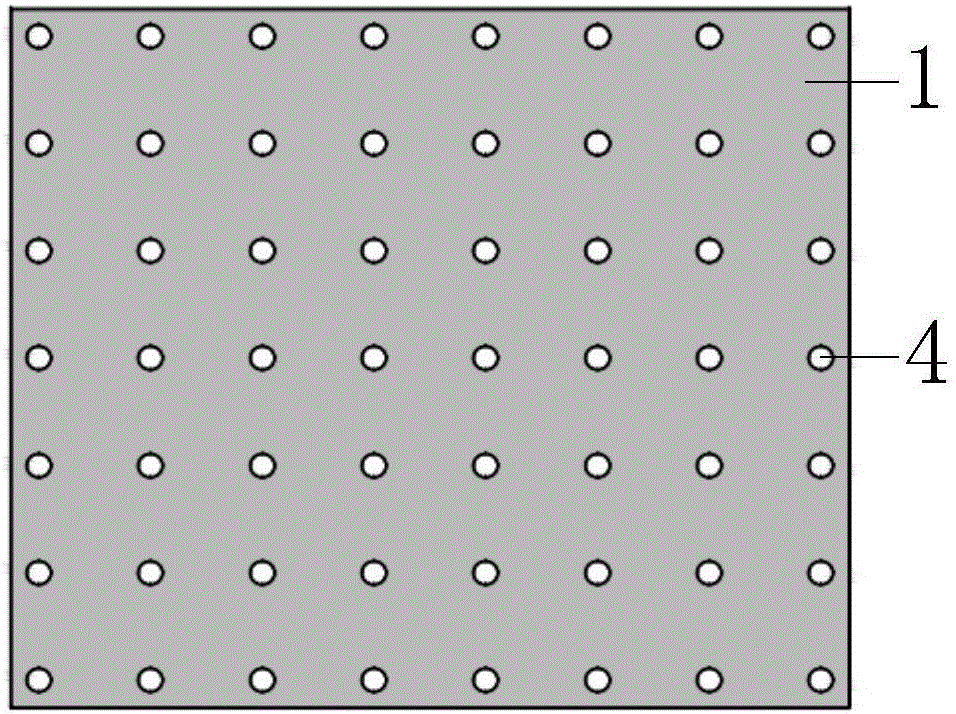

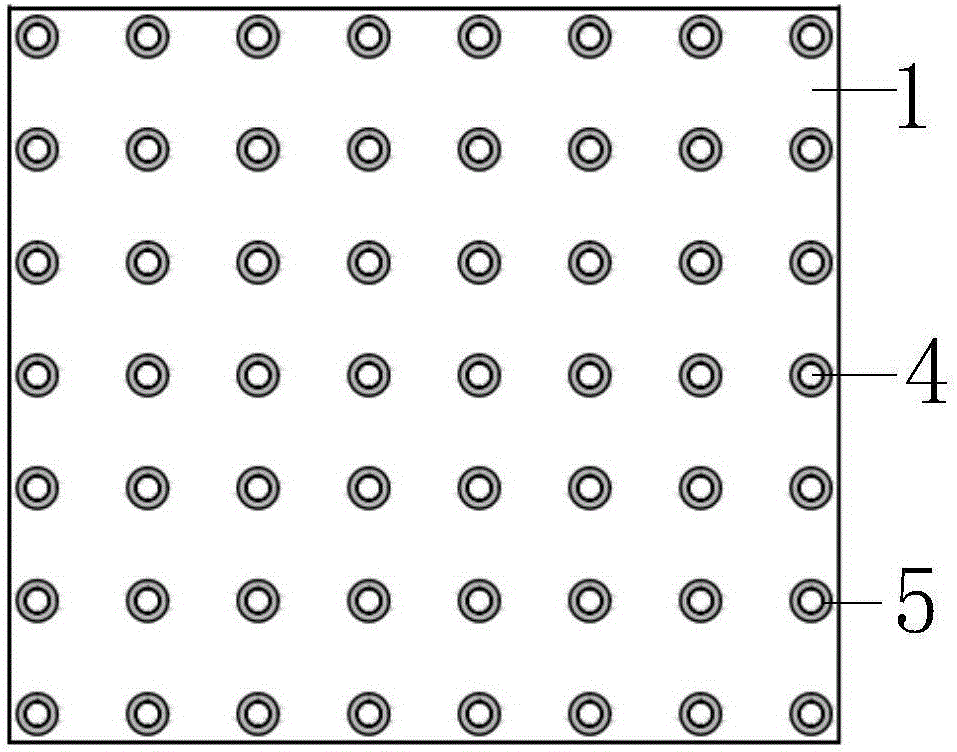

[0039] a. The upper surface of the top dielectric board (1) is printed with a metal layer, the dielectric board (1) is punched with periodic metal vias (4), and the lower surface of the dielectric board (1) is coated with periodic metal circular holes The patch (5), the periodic metal vias and the periodic metal circular patch (5) together form a mushroom-shaped electromagnetic bandgap (EBG) structure;

[0040] b. The middle dielectric board (2) is the gap layer, which is located in the middle of the top dielectric board (1) and the bottom dielectric board (3);

[0041] c. The upper surface of the bottom dielec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com