Variable pitch slip ring brush with an elastic conductive device

A slip ring brush, elastic conductive technology, applied in circuits, current collectors, electrical components, etc., can solve the problems of difficult cleaning and maintenance, poor contact, laborious, etc., to reduce product maintenance frequency, improve stability, and solve easy problems. break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiment of the pitch slip ring brush with the elastic conductive device of the present invention will be further described below in conjunction with the accompanying drawings.

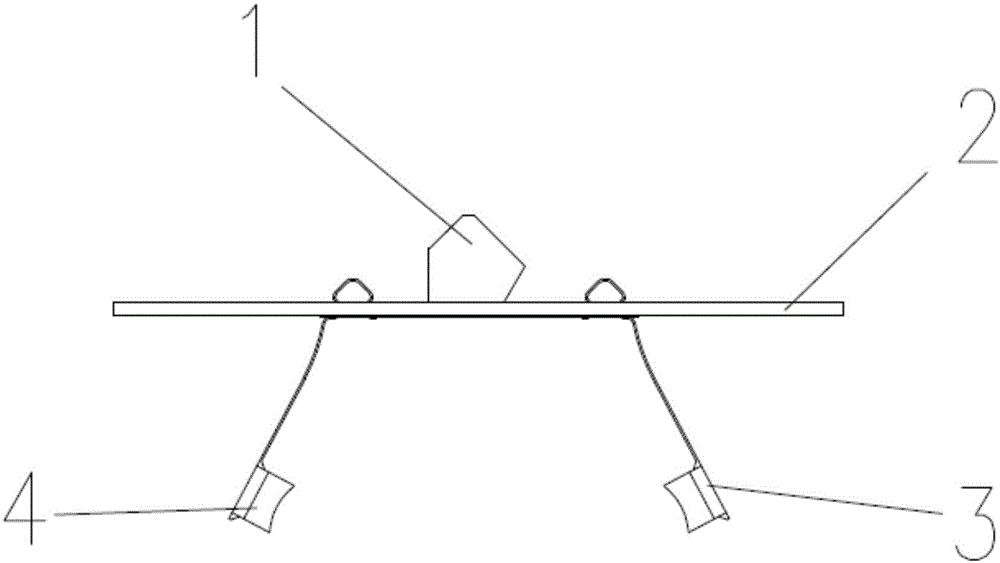

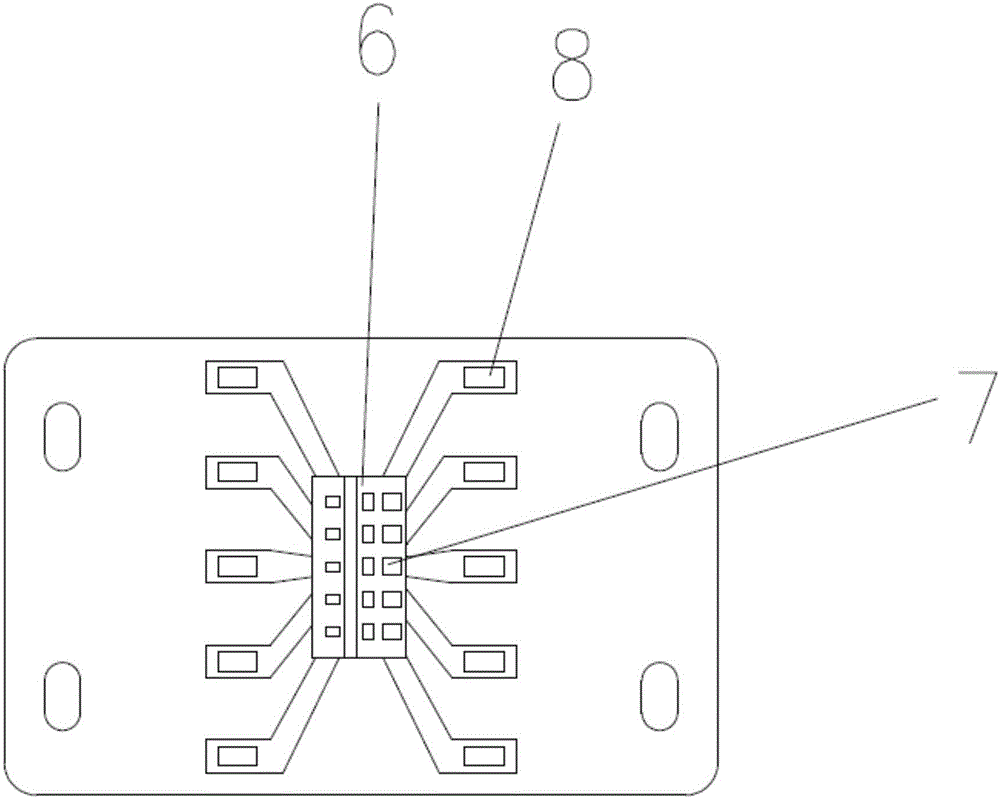

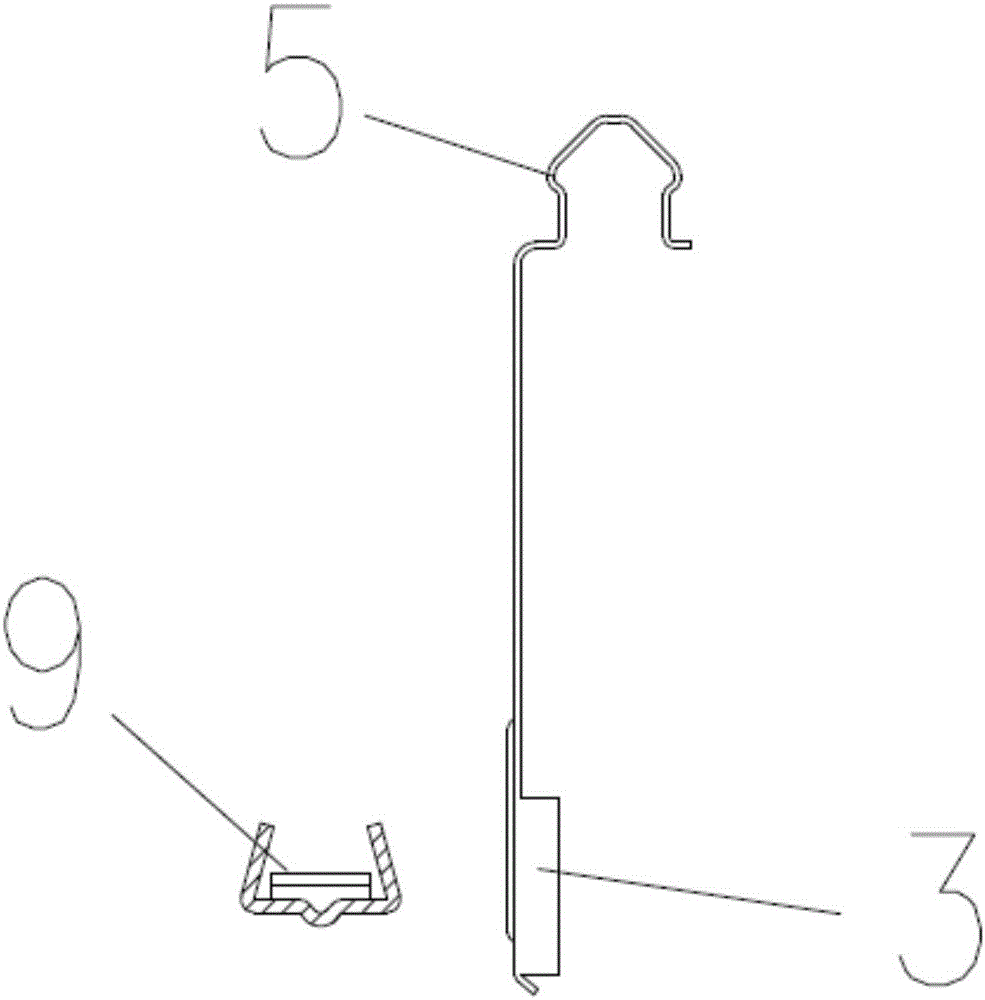

[0014] A pitch slip ring brush with an elastic conductive device, including a terminal 1, a circuit board 2, a contact shrapnel 3 and a brush, the terminal 1 is arranged on one side of the circuit board 2, the circuit board 2 and the terminal 1 There is an embedded copper conductive sheet 8 between them, square holes 8 are opened on both sides of the embedded copper conductive sheet 8, an elastic buckle 5 is provided on the contact shrapnel 3, and a square opening 7 is provided on the circuit board 2. The elastic buckle 5 of the point shrapnel 3 is installed in the square opening 7 of the circuit board 2. The electric brush is a dovetail brush 4. One end of the contact shrapnel 3 is provided with an elastic buckle 5, and the other end is connected with a reinforcing rib and The dovetail b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com