Passive plasma lightning expeller

A plasma and lightning arrester technology, applied in electrical components, circuits, corona discharge devices, etc., can solve the problems of lightning strikes, insufficient lightning clearance, and high failure probability of lightning clearance, so as to protect buildings, weaken the thunder cloud effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

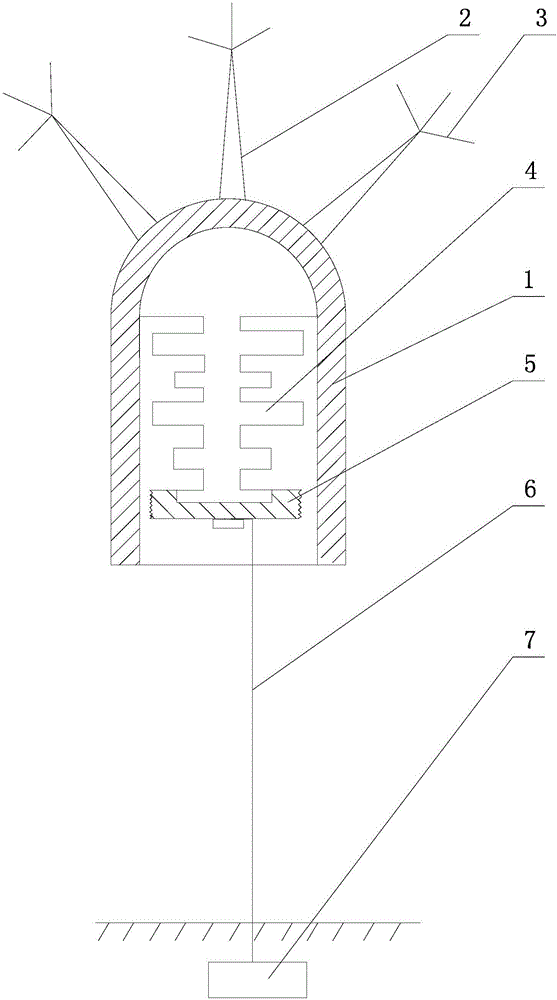

[0027] Such as figure 1 As shown, a passive plasma lightning drive device includes a metal cover 1, a plurality of discharge needles 2 are uniformly arranged on the outer wall of the metal cover 1, and a plurality of first-stage discharge needles 3 are arranged at the end of the discharge needle 2, and the inner wall of the opening end of the metal cover 1 is installed There is an insulator 4, the bottom of the insulator 4 is provided with an electrode 5, and the electrode 5 is spaced from the inner wall of the metal cover 1, and the electrode 5 is connected to the earth through the ground wire 6. By designing the metal cover 1, the discharge needle 2, the primary discharge needle 3 and The electrode 5 realizes that under the action of the thundercloud electric field, the primary discharge needle 3 and the thundercloud generate a passive primary discharge, and a passive secondary discharge is generated between the metal cover 1 and the electrode 5, and a large amount of plasma ...

Embodiment 2

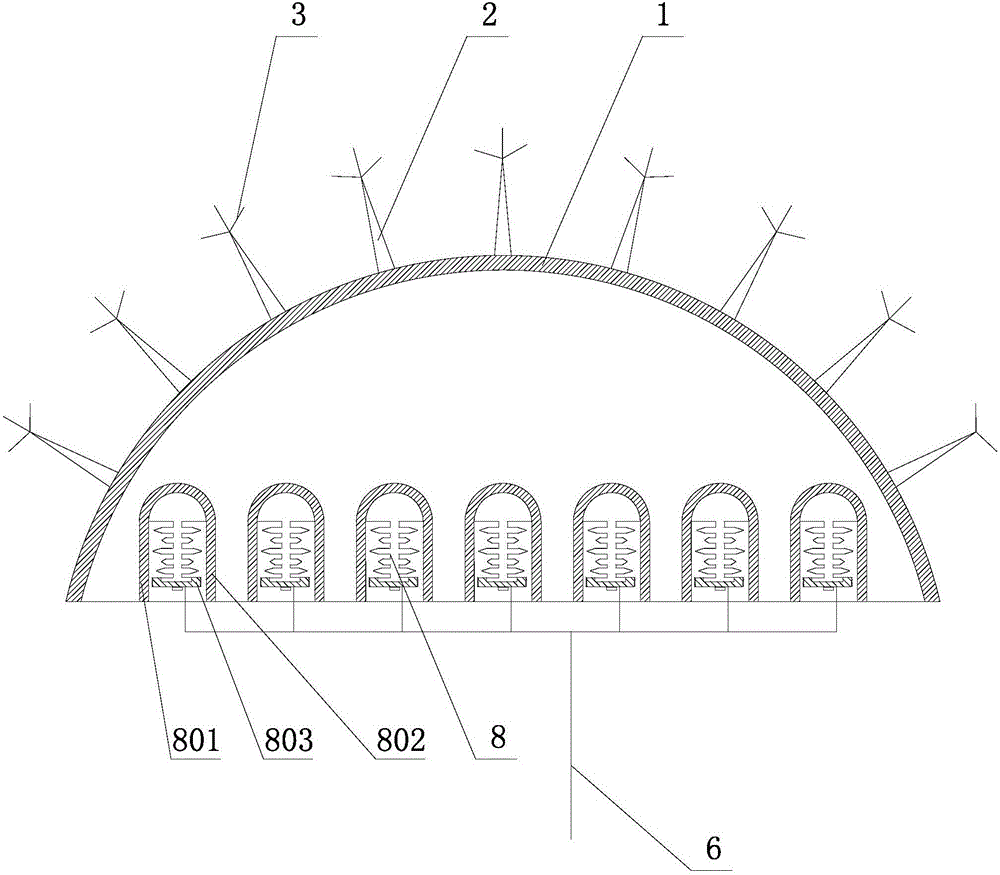

[0032] Such as figure 2 As shown, a single or multiple plasma generating chambers 8 are arranged inside the metal housing 1 , and a number of discharge needles 2 are uniformly arranged on the outer wall of the metal housing 1 .

[0033] A number of primary discharge needles 3 are arranged at the end of the discharge needle 2 .

[0034] The plasma generating chamber 8 includes a first metal outer cover 801, a first insulator 802 is installed on the inner wall of the opening end of the first metal outer cover 801, and a first electrode 803 is arranged at the bottom of the first insulator 802. The first electrodes 803 are arranged at intervals, and the first electrodes 803 are connected to the ground through the ground wire 6 to increase the amount of plasma generated.

[0035] The first metal housing 801 is connected to the metal housing 1 through wires

[0036] Embodiment 1 is example, illustrates the course of work of the present invention:

[0037] When there is thundercl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com