Micro-single-shell resonator

A single shell and resonator technology, applied in the field of micro-electromechanical systems, can solve problems such as parasitic capacitance and signal interference, affecting device performance, and large electrode and electrode areas, so as to reduce thermoelastic loss, low thermomechanical noise, and effective high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

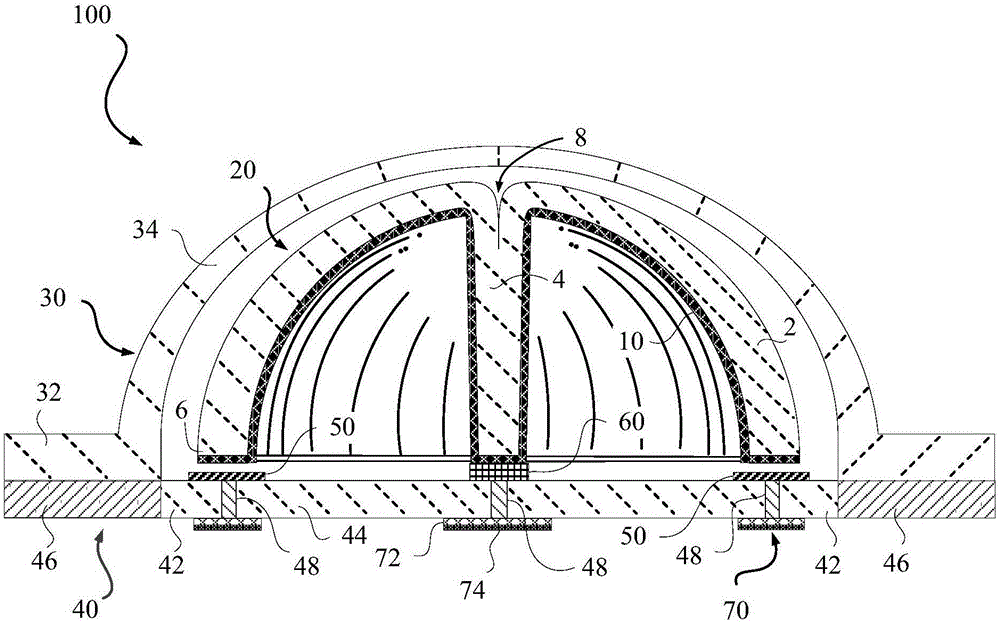

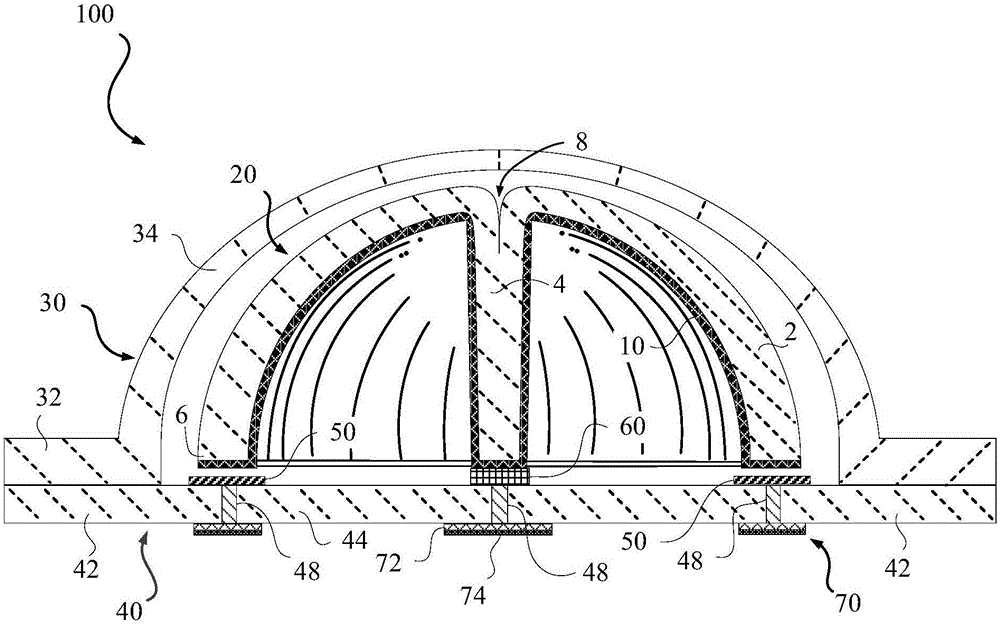

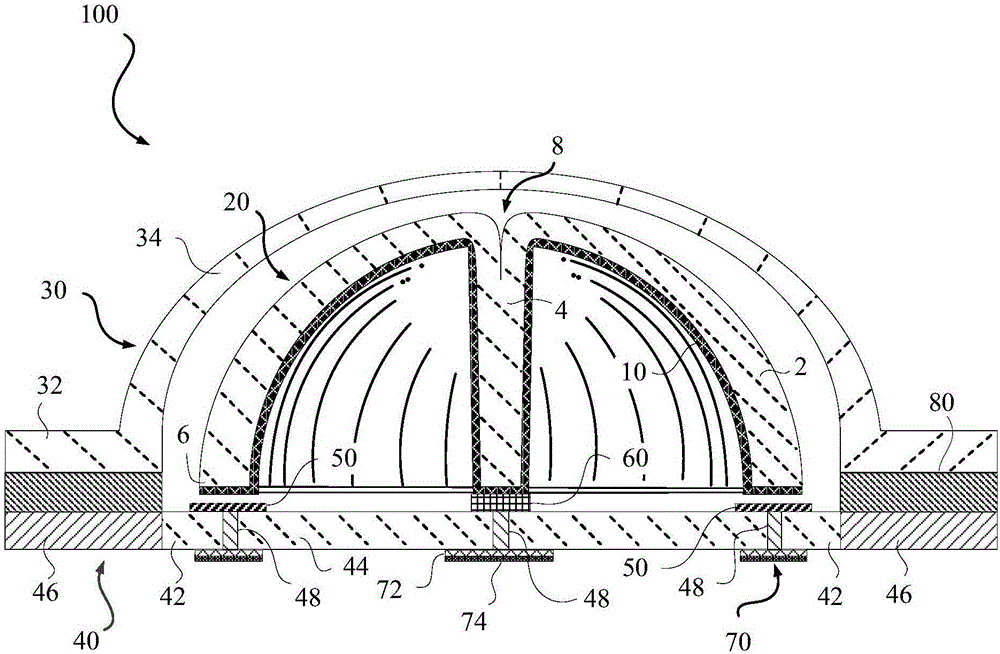

[0035] A micro monocoque resonator 100, comprising:

[0036] Encapsulation case cover 30;

[0037] Micro monocoque resonator 20;

[0038] planar electrode 50;

[0039] a composite structural substrate 40 with a plurality of conductive vias 48;

[0040] Wherein, the micro-single shell resonator 20 is composed of a single shell 2 and a single-end column 4 located at the inner central axis of the single shell 2; the bottom of the single-end column 4 and the bottom of the edge 6 of the single shell 2 flush; the single-end column 4 is connected and led out through a conductive through-hole 48 in the composite structure substrate 40 through a layer of conductive adhesive layer 60; there is a planar electrode 50 on the composite structure substrate 40; the planar electrode 50 passes through The conductive vias 48 located below are drawn vertically; the conductive vias 48 are drawn out through the conductive lead-out layer 70 on the back of the composite structure substrate 40; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com